Tea polyphenol nanoparticle stabilized Pickering emulsion and preparation method thereof

A technology of nanoparticles and tea polyphenols, which is applied in emulsion delivery, chemical instruments and methods, skin care preparations, etc. It can solve the problems of low content of antioxidant functional components, unsatisfactory antioxidant effect, and low concentration of antioxidants. , to achieve the effects of improving oxidation stability, anti-oxidation efficiency, prolonging effective action time, and reducing toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] A kind of preparation of the Pickering emulsion stabilized by cysteine tea polyphenol nanoparticles, specifically comprises the following steps:

[0038] (1) preparation of water phase: the cysteine EGCG nanoparticle is used as the stabilizer of Pickering emulsion, and it is mixed with deionized water into a solution whose mass concentration is 0.5%-4% as the water phase of Pickering emulsion;

[0039] (2) Preparation of Pickering Emulsion: Mix linseed oil with the water phase prepared in step (1) (water-oil ratio: 1:1), shear and emulsify (10000 rpm, 60 s) to obtain Pickering emulsion;

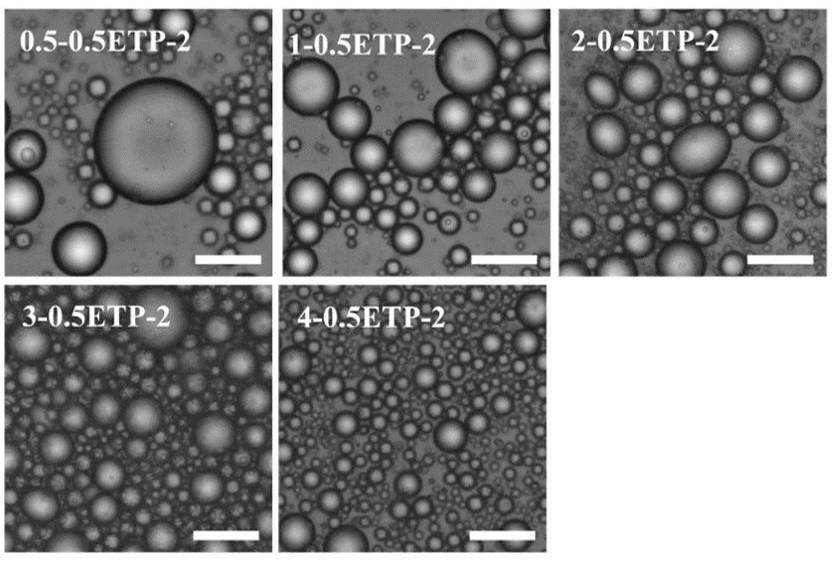

[0040] In this example, a gradient test was carried out on the mass concentration of cysteine EGCG nanoparticles in step (1), and the mass concentrations were 0.5%, 1%, 2%, 3%, and 4%, respectively. EGCG nanoparticle-stabilized Pickering emulsions (denoted as 0.5-0.5ETP-1, 1-0.5ETP-1, 2-0.5ETP-1, 3-0.5ETP-1, 4-0.5ETP-1, respectively). The emulsion layer height of the emulsion is...

example 2

[0046] The preparation of a glycine tea polyphenol nanoparticle-stabilized Pickering emulsion specifically comprises the following steps:

[0047] (1) preparation of water phase: the glycine EGCG nanoparticle is used as the stabilizer of Pickering emulsion, and it is mixed with deionized water into a solution with a mass concentration of 4% as the water phase of Pickering emulsion;

[0048] (2) Preparation of Pickering Emulsion: Mix linseed oil with the water phase prepared in step (1) (water-oil ratio: 2:3-3:7), shear emulsification (10000 rpm, 60 s) to obtain Pickering lotion;

[0049] In this example, a gradient test is carried out on the oil phase volume fraction in step (2). The volume fraction of linseed oil to the total system is 40%, 50%, 60%, and 70%, respectively. Pickering emulsions (denoted as 4-0.4ETP-2, 4-0.5ETP-2, 4-0.6ETP-2, 4-0.7ETP-2, respectively). The height of the emulsified layer of the emulsion is affected by the volume fraction of the oil phase. The l...

example 3

[0051] The preparation of a gelatinous glycine tea polyphenol nanoparticle-stabilized Pickering emulsion specifically comprises the following steps:

[0052] (1) preparation of water phase: the glycine EGCG nanoparticle is used as the stabilizer of Pickering emulsion, and it is mixed with deionized water into a solution with a mass concentration of 0.5% as the water phase of Pickering emulsion;

[0053] (2) Preparation of Pickering Emulsion: Mix linseed oil with the water phase prepared in step (1) (water-oil ratio: 2:3-3:7), shear emulsification (10000 rpm, 60 s) to obtain Pickering lotion;

[0054] (3) Preparation of gelatinous Pickering emulsion: add 2% PEG aqueous solution (the volume ratio of emulsion to PEG aqueous solution is 9:1) to the emulsion obtained in step (2), and then shear and emulsify (10000 rpm). , 30 s) to obtain a gel-like Pickering emulsion;

[0055] In this example, by simply adding PEG aqueous solution to the obtained low-concentration and fluid Picke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com