Symmetrical constraint roller type quenching device and quenching method for heat treatment reinforced aluminum alloy plate

A technology of aluminum alloy plate and quenching device, which is applied in the direction of quenching device, heat treatment furnace, heat treatment equipment, etc., can solve problems such as easy deformation, achieve fast adjustment speed, improve quenching quality, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

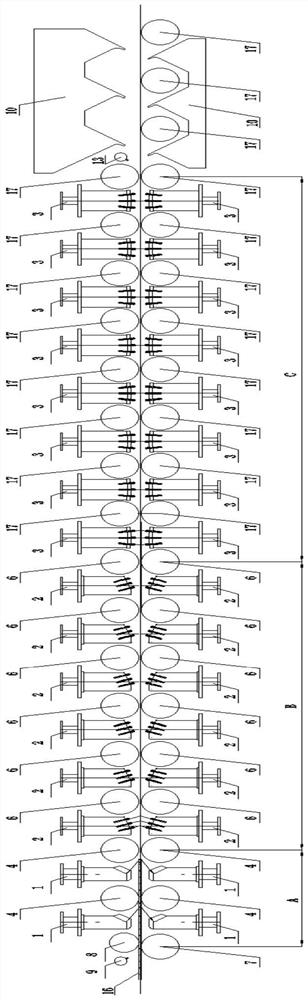

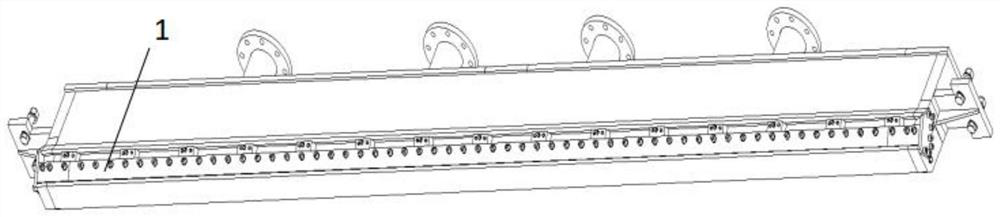

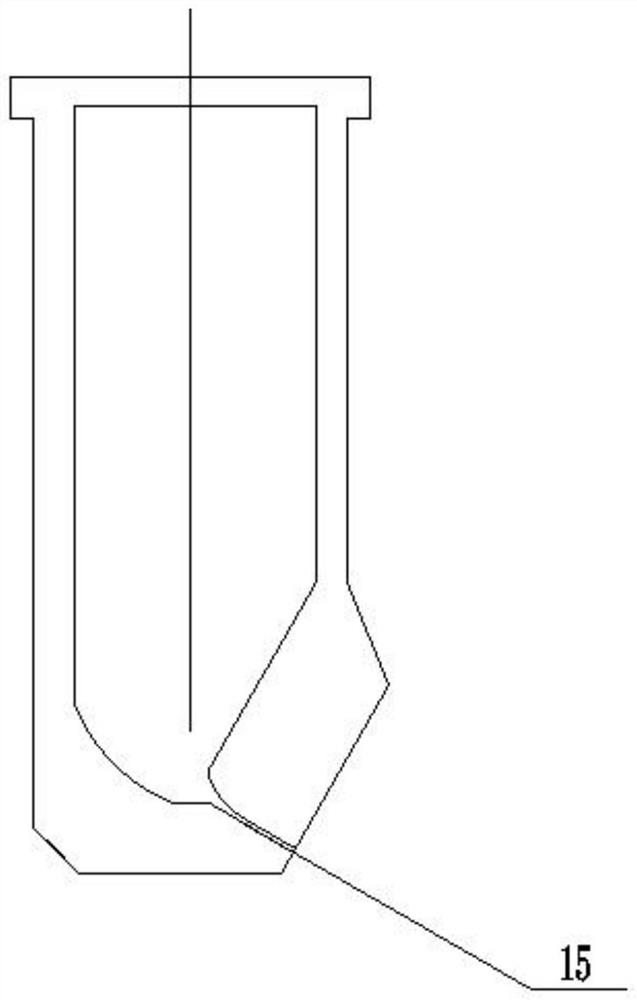

[0089] Example 1: (A quenching device and method for aluminum alloy sheet with a thickness of 3 to 20 mm)

[0090] Quenching device configuration: 1) 1 pair of slit nozzles 1 and 6 pairs of inclined fan nozzles 2 are arranged symmetrically up and down along the movement direction of the aluminum alloy plate 16; between the slit nozzle 1 and the first pair of inclined fan nozzles 2, and multiple pairs of inclined fan nozzles The spacing between the nozzles 2 along the movement direction of the aluminum alloy plate 16 is 500mm; the thickness of the slit 15 of the slit nozzle 1 is 1.5mm, the angle of the slit 15 is 30°, the spacing of the first nozzle 11 is 40mm, and the spraying The angle is 20°, and the included angle between the fan-shaped spray surface of the first nozzle 11 and the movement direction of the aluminum alloy plate 16 is 25°.

[0091] 2) Along the movement direction of the aluminum alloy plate 16, a high temperature resistant rubber spiral roller 4 is arranged a...

Embodiment 2

[0099] Embodiment 2: (A quenching device and method for aluminum alloy sheet with a thickness of 20 to 260 mm)

[0100] Quenching device configuration: 1) 2 pairs of slit nozzles 1, 6 pairs of inclined fan nozzles 2, 10 pairs of crown nozzles 3 are arranged symmetrically up and down along the movement direction of the aluminum alloy plate 16; The distances along the movement direction of the aluminum alloy plate 16 are all 500mm, between the first pair of crown-shaped nozzles 3 and the last pair of tilted fan-shaped nozzles 2, and between the plurality of pairs of crown-shaped nozzles 3 The spacing along the movement direction of the aluminum alloy plate 16 is 500mm; the thickness of the slit 15 of the slit nozzle 1 is 1.5mm, the angle of the slit 15 is 30°, and the spacing between any two first nozzles 11 is 40mm , the spray angle of the first nozzle 11 is 20°, the angle between the fan-shaped spray surface of the first nozzle 11 and the movement direction of the aluminum all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com