Device and treatment process for efficiently dealkalizing red mud in aluminum oxide production

A treatment process, alumina technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as increasing production costs, reduce environmental pressure, reasonable layout, and alkali removal rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

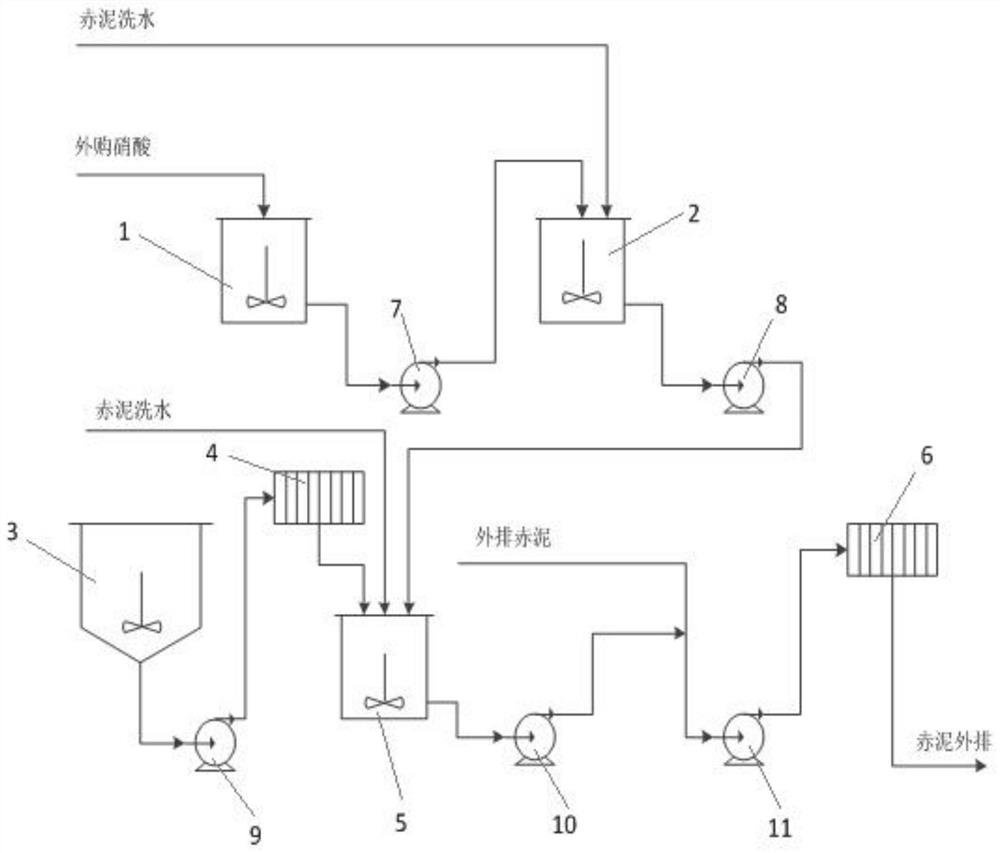

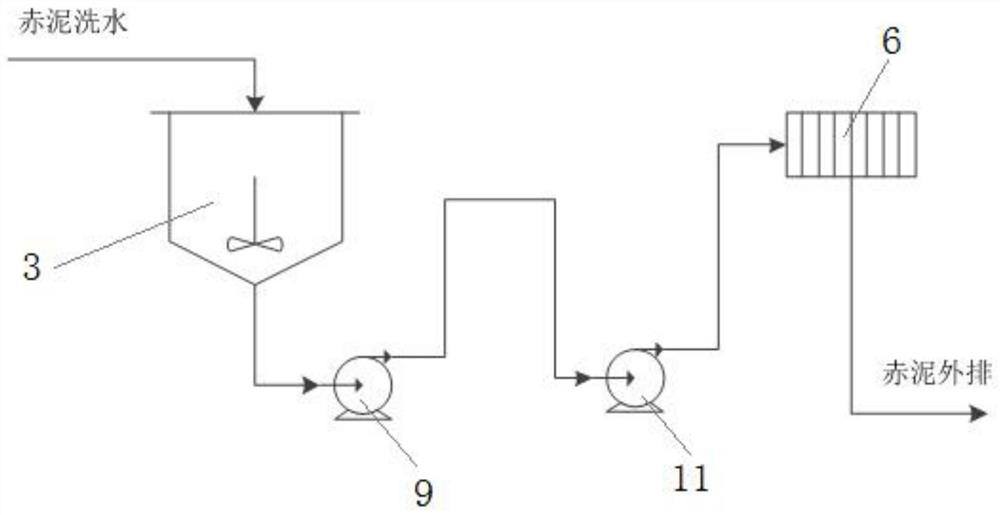

[0024] like figure 1 As shown, a device for high-efficiency dealkalization of red mud in alumina production includes a settling end washing tank 3, a dealkalizing plate-and-frame filter press 4, a reaction tank 5 and a plate-and-frame filter press 6, which are arranged in sequence. An underflow pump 9 is installed on the connecting pipeline of the settling end washing tank 3 and the dealkalizing plate and frame filter press 4, a slurry pump 10 is connected in front of the reaction tank 5, and a red slurry pump is connected in front of the slurry pump 10. Mud discharge diaphragm pump 11, the outlet of the red mud discharge diaphragm pump 11 is communicated with the plate and frame filter press 6; the outlet of the dealkalized plate and frame filter press 4 is communicated with the inlet of the reaction tank 5 , the inlet of the reaction tank 5 is communicated with the dilute nitric acid tank 2, and the dilute nitric acid pump 8 is installed on the communication pipeline of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com