Flexible liner for thermal treatment of magnetic alloy rings

A kind of alloy ring, flexible technology, applied in the direction of heat treatment furnace, heat treatment equipment, furnace, etc., can solve the problems of different crystallization shrinkage time, collapse of magnetic alloy ring, deformation of inner ring, etc., and achieve reasonable structural design and material selection, and use Convenience and ideal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

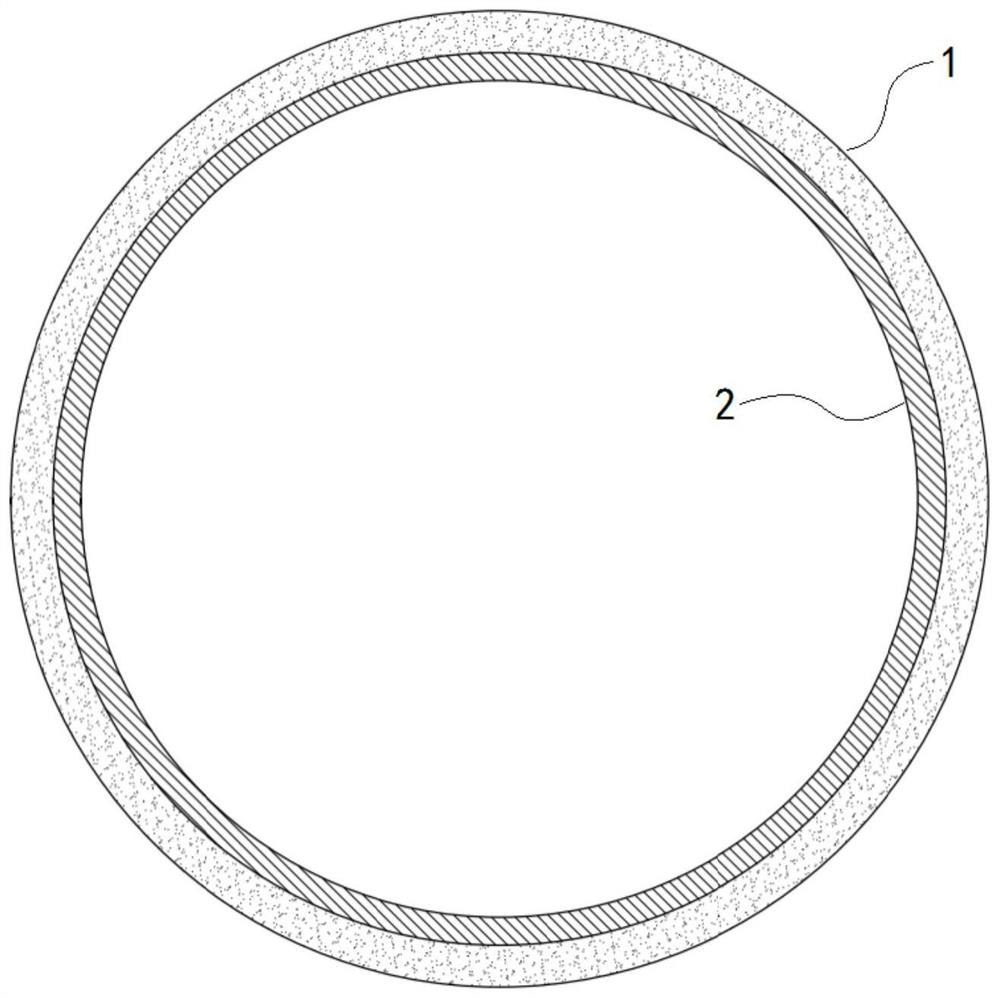

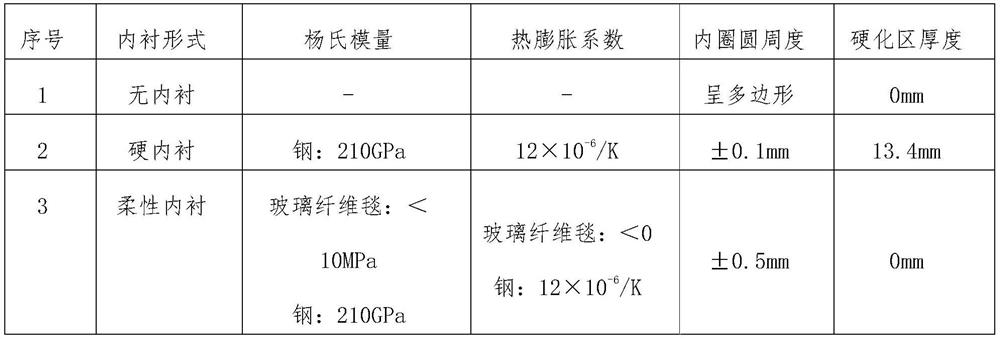

[0047] In this example, 3 large-sized magnetic alloy rings (outer diameter 500mm, inner diameter 300mm, height 25mm) with no inner lining, hard inner lining and flexible inner lining installed respectively are heat treated at 500°C, and the thickness of the hard inner lining material is 20 mm. The outer flexible material of the flexible inner lining is made of glass fiber blanket with a thickness of 10mm, and the inner rigid material is made of steel with a thickness of 10mm. Measure the hardened area of the magnetic alloy ring and the circumference of the inner ring after heat treatment, and the test results are as follows:

[0048] Table 1 Hardened zone of magnetic alloy ring and circumference of inner ring after heat treatment

[0049]

[0050] The magnetic permeability μ value test at 1MHz is carried out on the magnetic alloy ring after heat treatment, and the results are as follows:

[0051] Table 2 Magnetic permeability of magnetic alloy ring after heat treatment ...

Embodiment 2

[0055] In this example, magnetic alloy rings with inner linings of different materials are heat-treated at 500 °C, and the influence of different inner linings on magnetic alloy ring products is evaluated by measuring the circumference of the magnetic alloy ring after heat treatment at 500 °C, the hardened zone and the magnetic properties at 1 MHz. , Among them, the size of the magnetic alloy ring is selected as a large size magnetic alloy ring with an outer diameter of 800mm and an inner diameter of 400mm and a height of 30mm. The test results are as follows:

[0056] Table 3 Hardened zone of magnetic alloy ring and circumference of inner ring after heat treatment

[0057] serial number Lining form Young's modulus Thermal expansion coefficient Inner ring circumference Hardened zone thickness 1 steel 210GPa 12×10 -6 / K

±0.1mm 10.2mm 2 cement 30GPa 8×10 -6 / K

±0.2mm 8.2mm 3 fiberglass blanket <0 ±0.5mm 0mm

[0...

Embodiment 3

[0062] In this embodiment, the thickness (radial direction) of the flexible material in the flexible inner lining of the large-sized magnetic alloy ring is adjusted to conduct a heat treatment experiment. Among them, the flexible inner lining adopts the outer layer of glass fiber blanket, the inner layer is in the form of steel, the thickness of steel is fixed at 5mm, and the outer layer of glass fiber blanket adopts different thicknesses of 1mm, 2mm, 5mm, 10mm, 20mm, and the outer diameter is 800mm. The large size magnetic alloy ring with an inner diameter of 400mm and a height of 30mm is heat-treated at 500°C. The influence of the thickness of the flexible material in the flexible lining on the magnetic alloy ring product was evaluated by measuring the circumference of the magnetic alloy ring after heat treatment, the hardened zone and the magnetic properties at 1MHz. The test results are as follows:

[0063] Table 5 Hardened zone of magnetic alloy ring and circumference of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com