Wear-resistant TiSiCN nano-composite multilayer coating and preparation method thereof

A multi-layer coating and nano-composite technology, which is applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems that cannot meet the requirements of better performance of materials, and achieve huge market potential and use value , low production cost, and improved mechanical wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

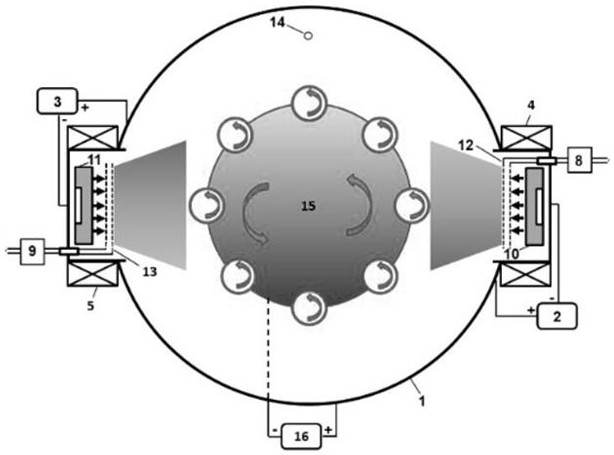

[0037]1) After degreasing and polishing the surface of the stainless steel, put it into acetone for ultrasonic cleaning. After cleaning, the substrate is cleaned with alcohol, then dried with nitrogen and placed on the turret 15 of the vacuum chamber 1 of the coating equipment. Pump to vacuum less than 5×10 -4 Pa, while heating to 400 ℃;

[0038] 2) First pass Ar gas into the vacuum chamber, adjust the intake flow rate through the flow meter, keep the air pressure of the vacuum chamber at 1.0Pa, then turn on the bias power supply, adjust the bias value to -1000 V, and carry out Ar glow cleaning on the workpiece The time is 10-20 min; then, a Ti target power supply is turned on at the same time, the DC mode is adopted, the DC current is 120 A, the air pressure of the vacuum chamber is kept at 1.0 Pa, the bias value is -1000 V, and the workpiece ion cleaning time is 10 min , to obtain the workpiece to be plated;

[0039] 3) Deposition of transition layer Ti / TiN / TiCN: turn on t...

Embodiment 2

[0045] 1) After degreasing and polishing the surface of the stainless steel, put it into acetone for ultrasonic cleaning for 5-10 minutes. After cleaning, the substrate is cleaned with alcohol, then dried with nitrogen and placed on the turret 15 of the vacuum chamber 1 of the coating equipment. , pump the vacuum chamber 1 to a degree of vacuum less than 5×10 -4 Pa, while heating to 400 ℃;

[0046] 2) First pass Ar gas into the vacuum chamber, adjust the intake flow rate through the flow meter, keep the air pressure of the vacuum chamber at 1.0Pa, then turn on the bias power supply, adjust the bias value to -600 V, and perform Ar glow cleaning on the workpiece The time is 5-10 min; then, a Ti target power supply is turned on at the same time, the DC mode is adopted, the DC current is 30 A, the air pressure of the vacuum chamber is kept at 0.3 Pa, the bias value is -600 V, and the workpiece ion cleaning time is 1 min , to obtain the workpiece to be plated;

[0047] 3) Deposit...

Embodiment 3

[0052] 1) After degreasing and polishing the surface of the high-speed steel, put it into acetone for ultrasonic cleaning for 5-10 minutes, and then clean the cleaned substrate with alcohol, then dry it with nitrogen and place it on the turret 15 of the vacuum chamber 1 of the coating equipment. , pump the vacuum chamber 1 to a degree of vacuum less than 5×10 -4 Pa, while heating to 400 ℃;

[0053] 2) First pass Ar gas into the vacuum chamber, adjust the intake flow rate through the flowmeter, keep the air pressure of the vacuum chamber at 0.8 Pa, then turn on the bias power supply, adjust the bias value to -1000 V, and carry out Ar glow cleaning on the workpiece The time is 10-20min; then, a Ti target power supply is turned on at the same time, the DC mode is adopted, the DC current is 120 A, the air pressure of the vacuum chamber is kept at 1.0 Pa, the bias value is -1000 V, and the workpiece ion cleaning time is 10 min. Obtain the workpiece to be plated;

[0054] 3) Depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com