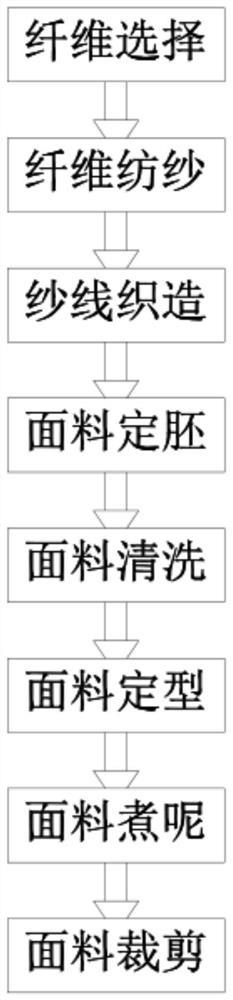

Production process of Sorona elastic yarn-dyed fabric

A production process and fabric technology, applied in the field of fabric production, can solve problems such as inconvenience in production work, and achieve the effect of comfortable and cool wearing, high strength, silky effect and feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]The production process of Sorona stretch yarn-dyed fabric is as follows: The production process of Sorona stretch yarn-dyed fabric includes the following steps: selecting bamboo fiber, cupro fiber, chitin fiber, cotton fiber and Sorona fiber as raw materials; The technological process is: blowing and carding → combing preparation → combing → first drawing frame → second drawing frame → roving → spun yarn, cotton fiber and chitin fiber are blended to make A yarn, and A yarn is used as the surface. Thread, blending cupro fiber and bamboo fiber to make B yarn, using B yarn as the middle construction line, and finally spinning the sorona fiber yarn as the inner thread; using a rapier loom, in order to open the shed, smoothly Weft insertion, so that the height of the shed is 32cm, and the rapier will not be squeezed by the upper and lower warp yarns when entering and leaving the shed. The selvage is well formed, the right hemming leveling time is 300 seconds, and the upper ma...

Embodiment 2

[0042] The production process of Sorona stretch yarn-dyed fabric is as follows: The production process of Sorona stretch yarn-dyed fabric includes the following steps: selecting bamboo fiber, cupro fiber, chitin fiber, cotton fiber and Sorona fiber as raw materials; The technological process is: blowing and carding → combing preparation → combing → first drawing frame → second drawing frame → roving → spun yarn, cotton fiber and chitin fiber are blended to make A yarn, and A yarn is used as the surface. Thread, blending cupro fiber and bamboo fiber to make B yarn, using B yarn as the middle construction line, and finally spinning the sorona fiber yarn as the inner thread; using a rapier loom, in order to open the shed, smoothly Weft insertion, so that the height of the shed is 35cm, and the rapier will not be squeezed by the upper and lower warp yarns when entering and leaving the shed. The selvage is well formed, the right hemming and levelling time is 306 seconds, and the up...

Embodiment 3

[0044] The production process of Sorona stretch yarn-dyed fabric is as follows: The production process of Sorona stretch yarn-dyed fabric includes the following steps: selecting bamboo fiber, cupro fiber, chitin fiber, cotton fiber and Sorona fiber as raw materials; The technological process is: blowing and carding → combing preparation → combing → first drawing frame → second drawing frame → roving → spun yarn, cotton fiber and chitin fiber are blended to make A yarn, and A yarn is used as the surface. Thread, blending cupro fiber and bamboo fiber to make B yarn, using B yarn as the middle construction line, and finally spinning the sorona fiber yarn as the inner thread; using a rapier loom, in order to open the shed, smoothly Weft insertion, so that the height of the shed is 39cm, and the rapier will not be squeezed by the upper and lower warp yarns when entering and leaving the shed. The selvage is well formed, the right hemming and levelling time is 312 seconds, and the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com