Optical sensor based on surface lattice resonance and testing method thereof

An optical sensor, lattice technology, applied in transmittance measurement and other directions, can solve the problems of weakening SLR local field strength and increasing bandwidth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

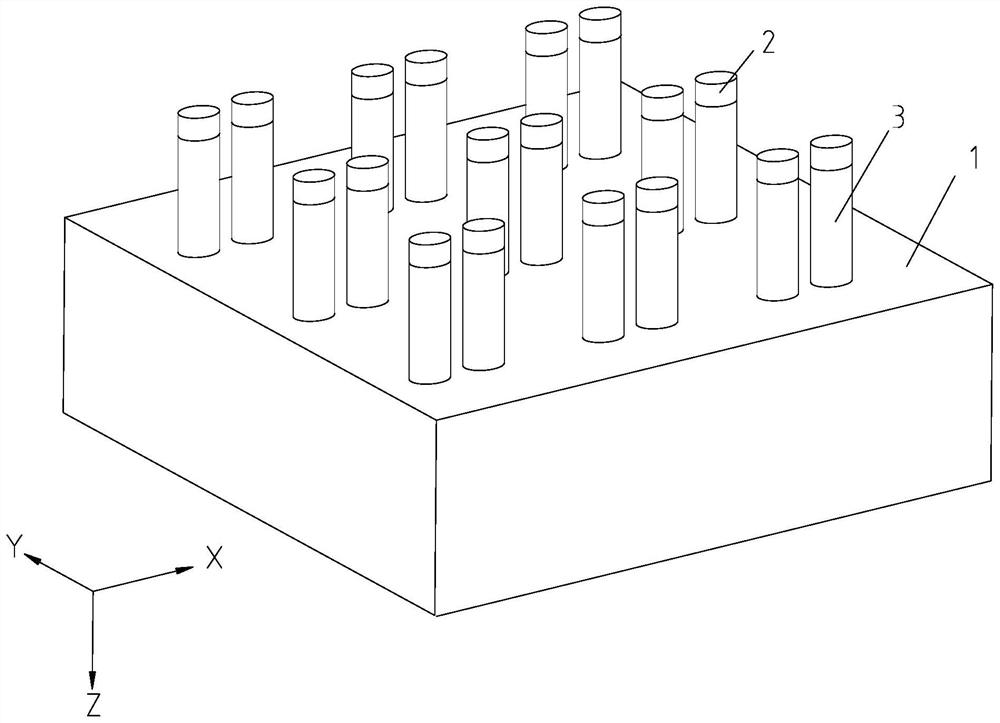

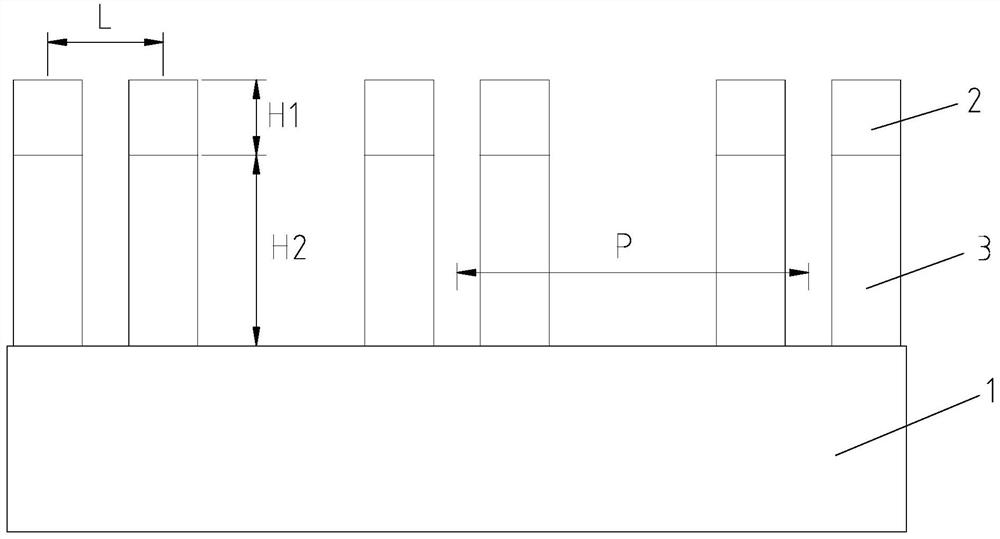

[0037] like figure 1 , 2 As shown, an optical sensor based on surface lattice resonance consists of a quartz substrate and a silicon / silicon dioxide nanopillar dimer array on the quartz substrate; the silicon / silicon dioxide nanopillar dimer array is composed of silicon / Silica nanopillar dimer is periodically and uniformly arranged; the silicon / silicon dioxide nanopillar dimer includes two spaced silicon / silicon dioxide nanopillars, the silicon / silicon dioxide nanopillar The nano-columns include silicon nano-columns 2 and silicon dioxide nano-columns 3 arranged in sequence from top to bottom.

[0038] The diameters of the two silicon / silicon dioxide nanopillars in the silicon / silicon dioxide nanopillar dimer are both 80 nm, and the height H1 of silicon nanopillar 2 is 100 nm; the height H2 of silicon dioxide nanopillar 3 is 900 nm; The center-to-center distance L between two silicon / silicon dioxide nanopillars in the silica nanopillar dimer is 90 nm; the period P of the arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com