Waste gas and sewage efficient treatment device for graphite reaction kettle

The technology of a treatment device and a reaction kettle is applied in the field of high-efficiency treatment devices for waste gas and sewage, which can solve the problems affecting the environmental protection of the device, reduce the cleaning efficiency, and reduce the practicability of the device, so as to improve the overall practicability, the service life, and the practicality of the device. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

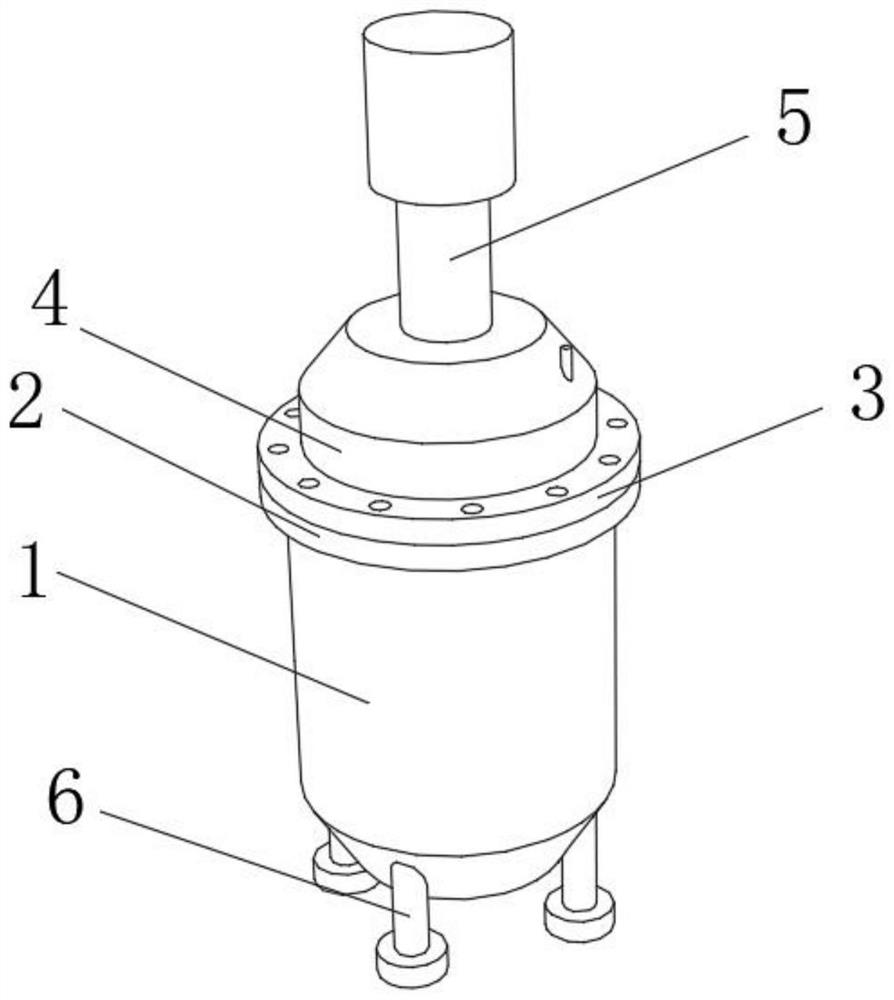

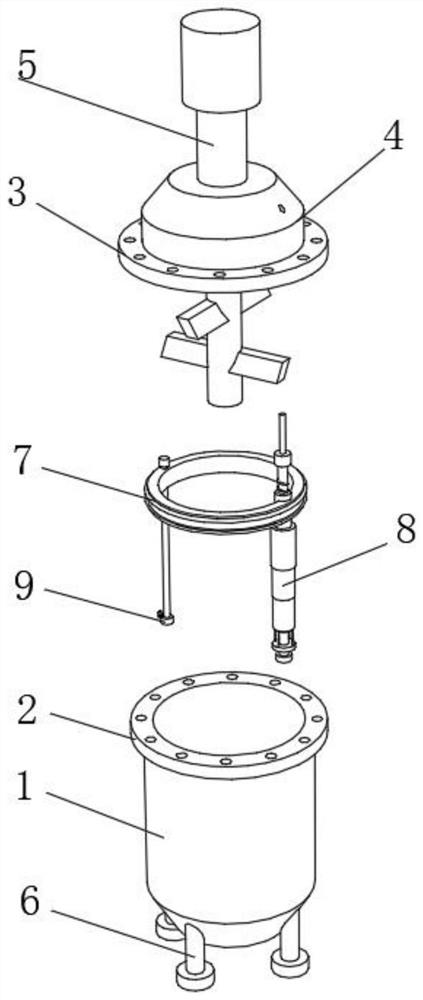

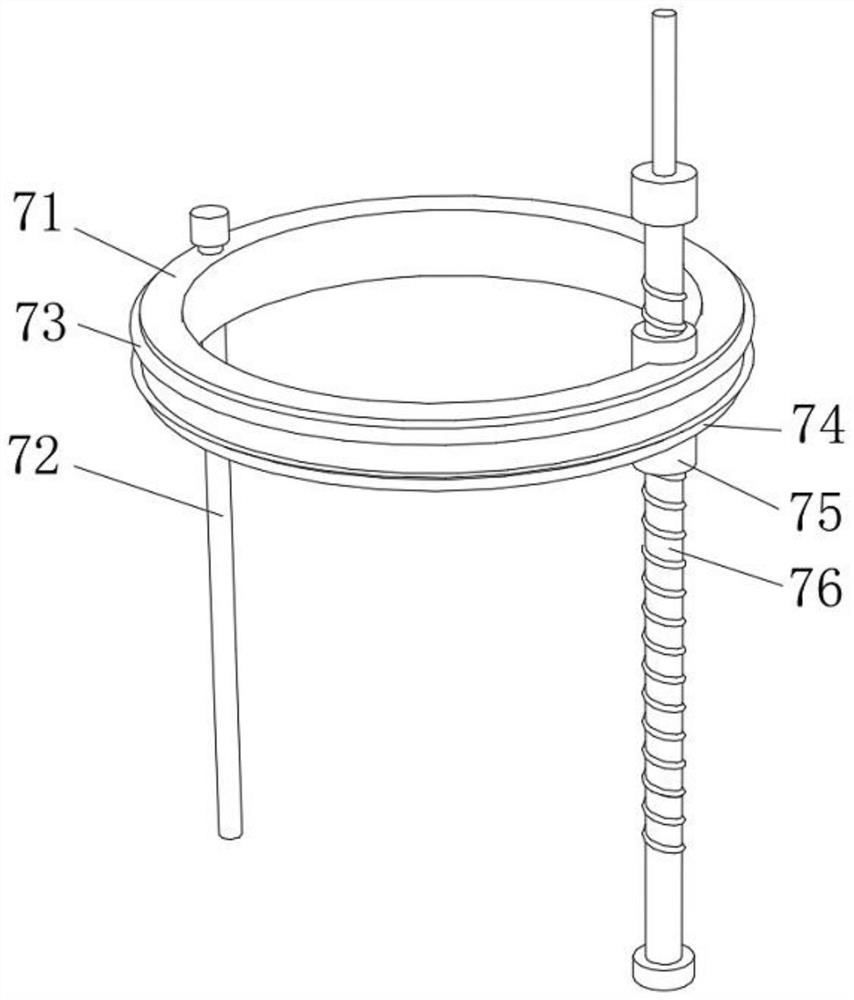

[0025] Attached to the following Figure 1-5 The present invention will be described in further detail.

[0026] see Figure 1-5 , the present invention provides a technical solution: a high-efficiency treatment device for waste gas and sewage for graphite reactors, such as Figure 1-3 As shown, it includes a tank 1, a first flange 2 is fixedly installed on the top surface of the tank 1, a second flange 3 is detachably installed on the top surface of the first flange 2, and the second flange 3 A tank cover 4 is fixedly installed on the top surface of the tank cover 4, a driving device 5 is installed in the middle of the top surface of the tank cover 4, and a supporting leg 6 is fixedly installed on the bottom surface of the tank body 1. The surface of the tank cover 4 is provided with a circular hole, and the inner The acceleration assembly 7 is rotatably installed, the surface of the acceleration assembly 7 is movably installed with a protection assembly 8, the bottom end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com