Production process and application of small-section high-strength alloy steel welding product

A production process, high-strength technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of damage to the welding point and the metallographic structure of the base material, unable to meet the requirements of product characteristics, brittle fracture and impact resistance, etc. The problem is to shorten the heat treatment time, solve the brittle fracture of the weld scar, and improve the tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

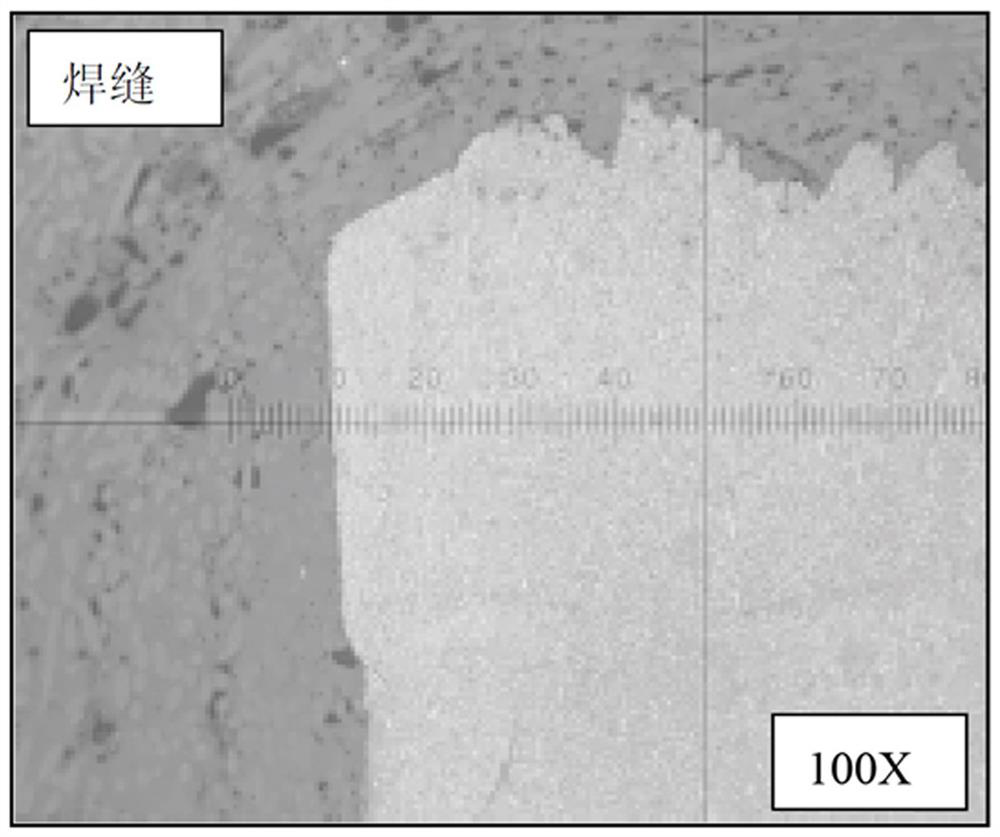

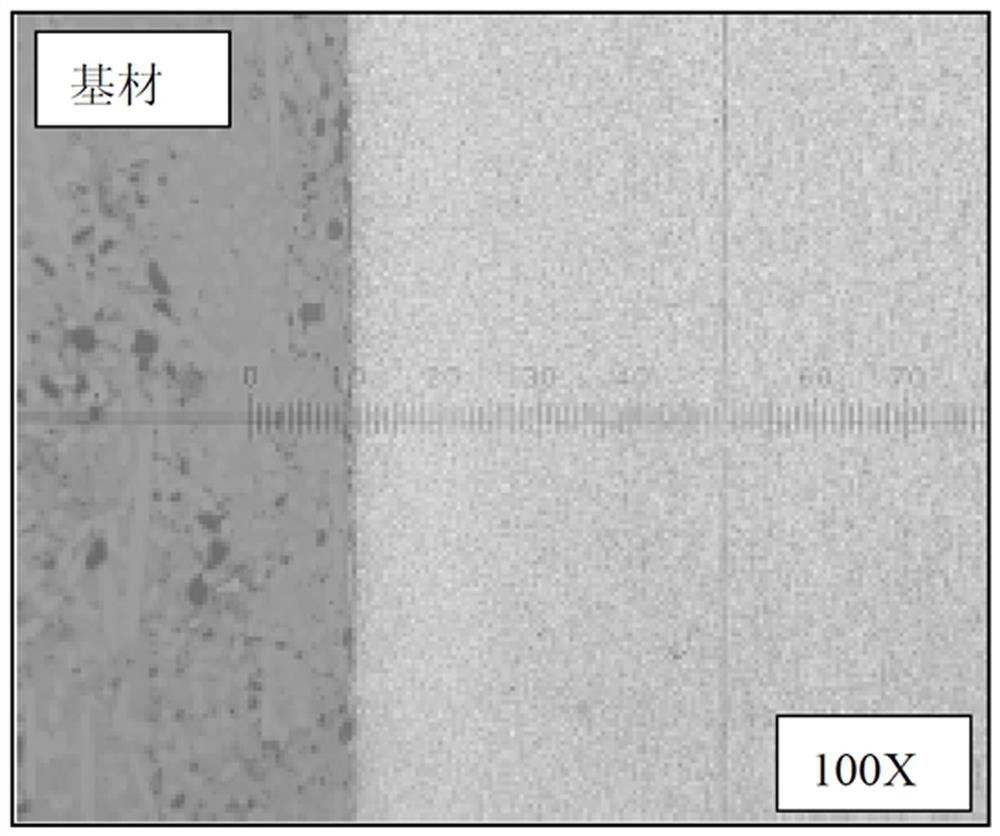

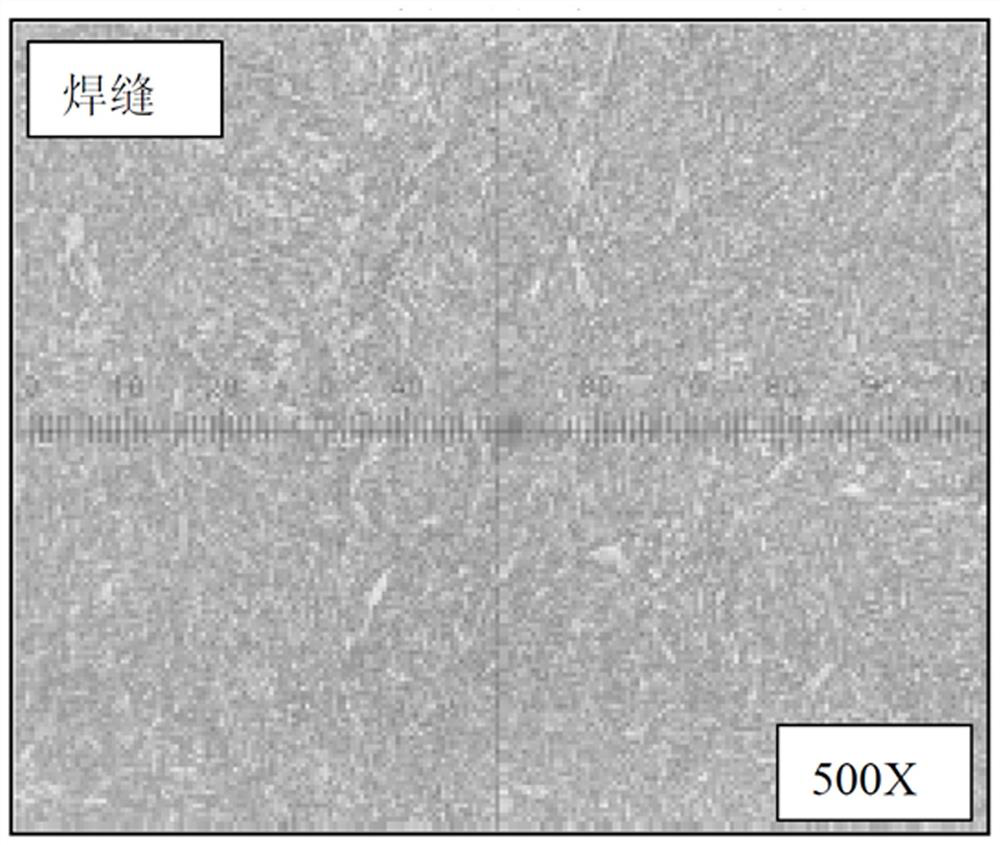

[0034] combined with figure 1 ~attached Figure 8 , In this embodiment, a production process for a small-section high-strength alloy steel welded product is proposed, and the process includes workpiece pre-forming, fiber laser welding, local rapid heat treatment, tempering and other processes; wherein the workpiece pre-forming process In order to cut high-strength alloy steel profiles near-line, and then pre-form the workpiece into a rectangular shape or a ring shape with unconnected ends by pre-forming equipment (such as lathes, stamping equipment or winding equipment); The local area of the preformed workpiece to be welded is placed in the cleaning equipment through the fixture for local cleaning and cleaning to remove oil stains, rust or other impurities on the surface.

[0035] The fiber laser welding process is as follows: the partially cleaned preformed workpiece is dried by other drying methods such as air drying equipment, natural drying or low temperature drying. A...

Embodiment 2

[0039] combined with figure 1 ~attached Figure 8 , The difference between this embodiment and Embodiment 1 is that in this embodiment, the output power of the electrode heat treatment equipment is 3kw during local heat treatment, the local heat treatment time is 1.5~3s / piece, and the heat treatment temperature is set to 651~700℃ or 701~ 750℃, the distance of local heat treatment is set to 6~10mm or 11~30mm; it is also different from the tempering process, which adopts the local tempering process, and the local heat treatment equipment used is the same, which is different from the local heat treatment. The output of the electrode heat treatment equipment The power and the local tempering temperature are different, among which the output power of the local tempering treatment is 2kw; the local tempering temperature is 300 ~ 500 ℃.

Embodiment 3

[0041] combined with figure 1 ~attached Figure 8 , the difference between this example and Example 1 and Example 2 is that in this example, the output power of the electrode heat treatment equipment during local heat treatment is 6.5kw, the local heat treatment time is 1.5 ~ 3s / piece, and the heat treatment temperature is set to 500 ~800°C, the distance of local heat treatment is set to be 11-30 mm; this embodiment and embodiment 2 are also different from the tempering treatment process by adopting the overall tempering treatment process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com