Production process of glass fiber composite material

A glass fiber and composite material technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor wear resistance, brittleness, large glass fiber covering area, etc., and achieve the effect of easy installation and disassembly, and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

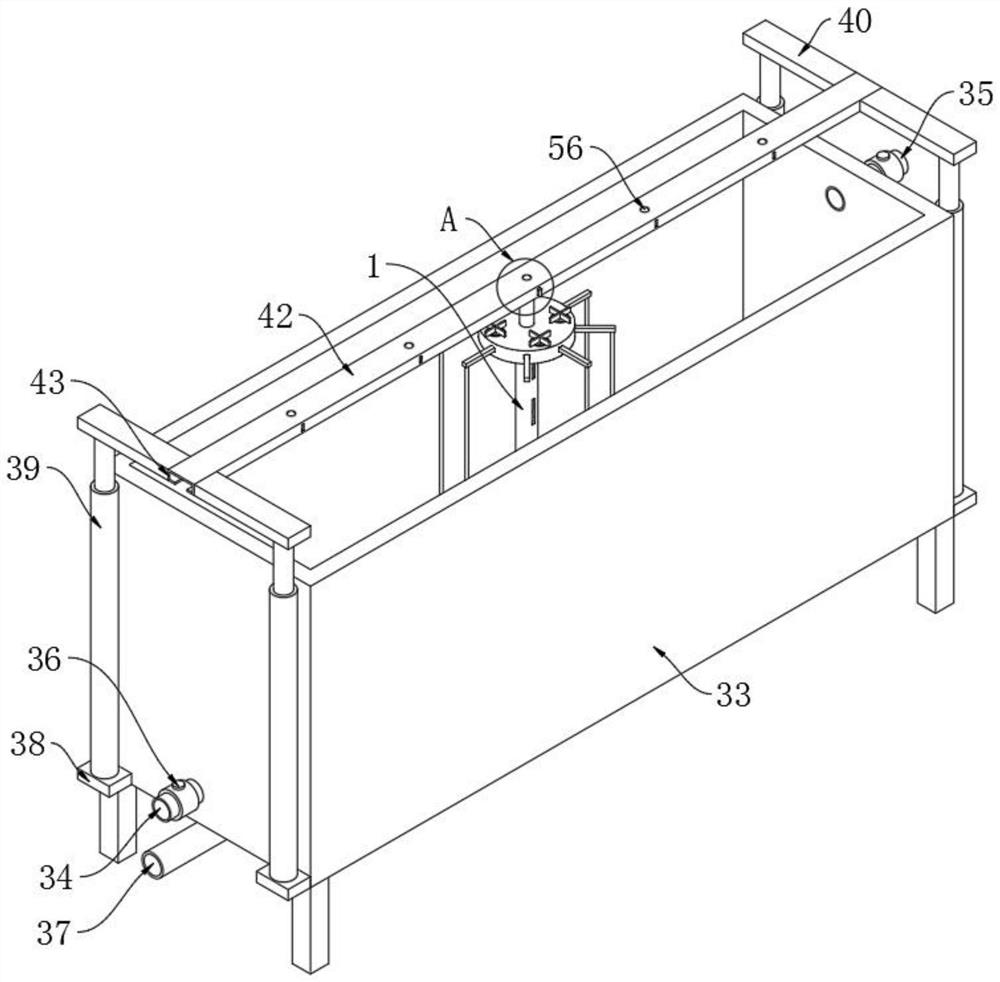

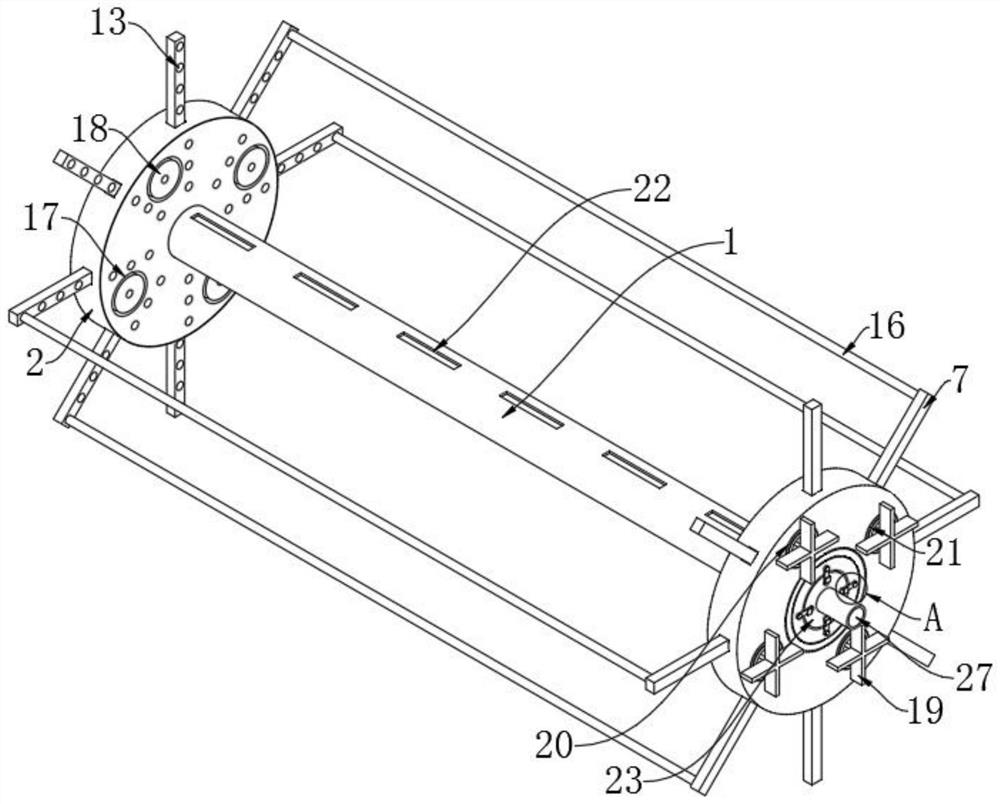

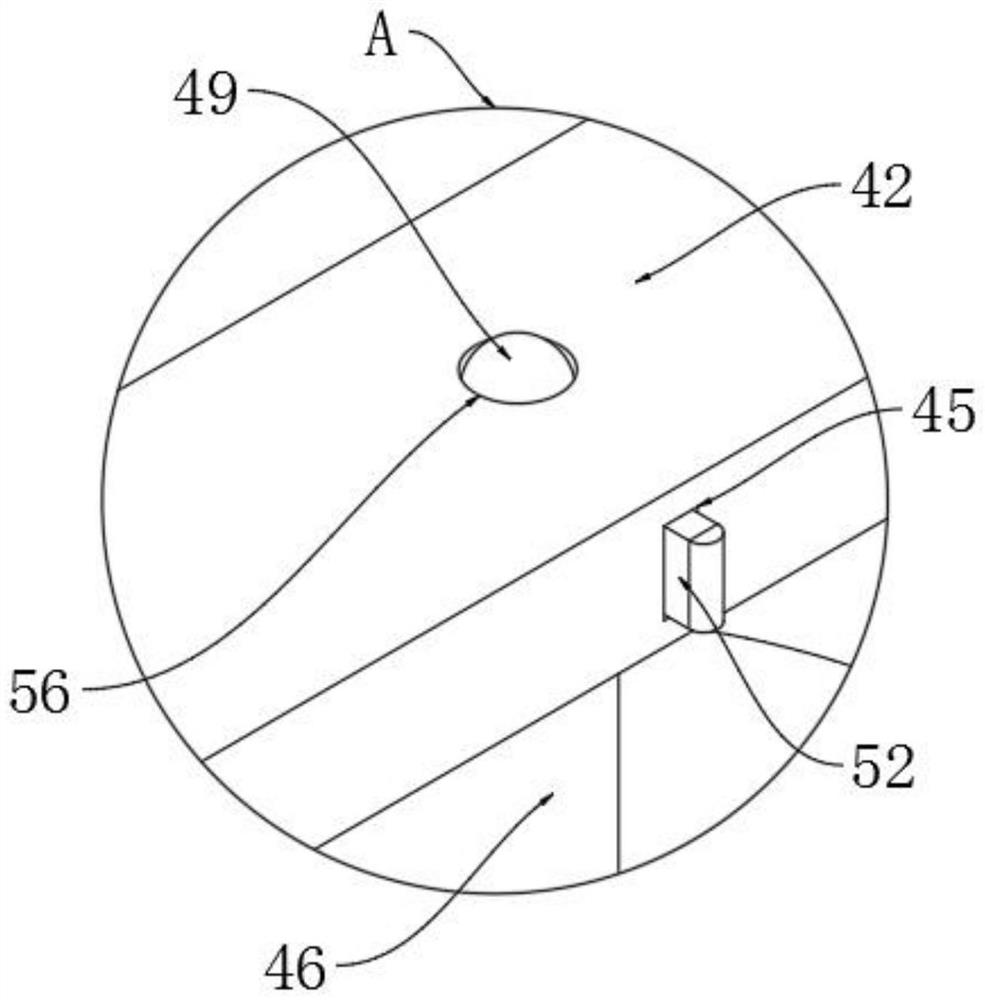

[0053] Example: as Figure 1-14 As shown, a kind of glass fiber composite material production process of the present invention comprises the following steps:

[0054] Raw material screening and mixing: screen the glass fiber raw materials, select the raw materials, mix the raw materials, and mix them evenly;

[0055] S2, wire drawing: the mixed raw materials are melted and drawn to obtain glass fibers;

[0056] S3. Pickling: wind the glass fiber on the winding device, put the wound glass fiber into the pickling mechanism, and carry out the pickling treatment;

[0057] S4, water washing: take out the glass fiber after pickling, clean the glass fiber by spraying warm water, remove the residual acid on the surface, and put the glass fiber into the pool for soaking after spraying;

[0058] S5, heat treatment: put the cleaned glass fiber into the heat treatment furnace for shaping processing;

[0059] S6. Infiltration and plying: put the formed glass fibers into the infiltration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com