Arylamine compound containing multiple sulfonic groups and preparation method thereof

A polysulfonic acid group arylamine and polysulfonic acid group technology, which is applied in the field of polysulfonic acid group-containing aromatic amine compounds and its preparation, can solve the problem of difficulty in greatly increasing the number of sulfonic acid groups, pollution, and three wastes, etc. problems, to achieve the effects of reduced energy consumption, simple operation of the preparation process, and significant low-temperature storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

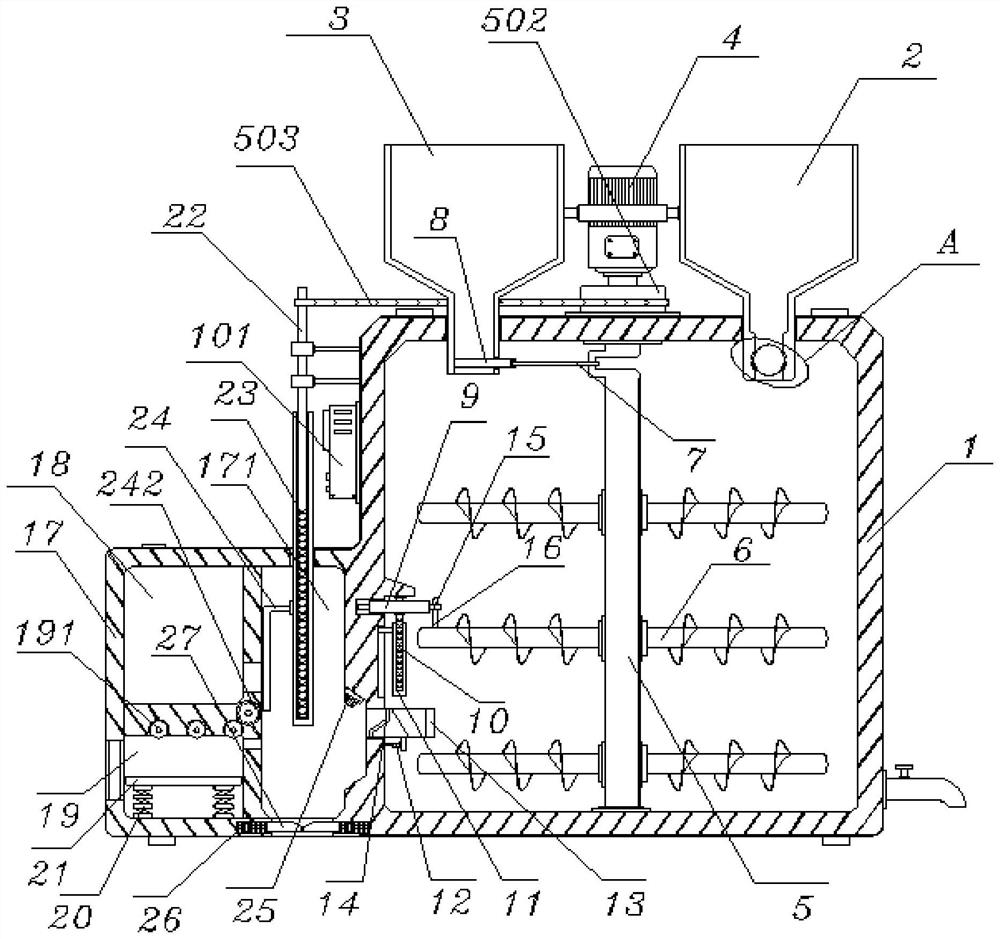

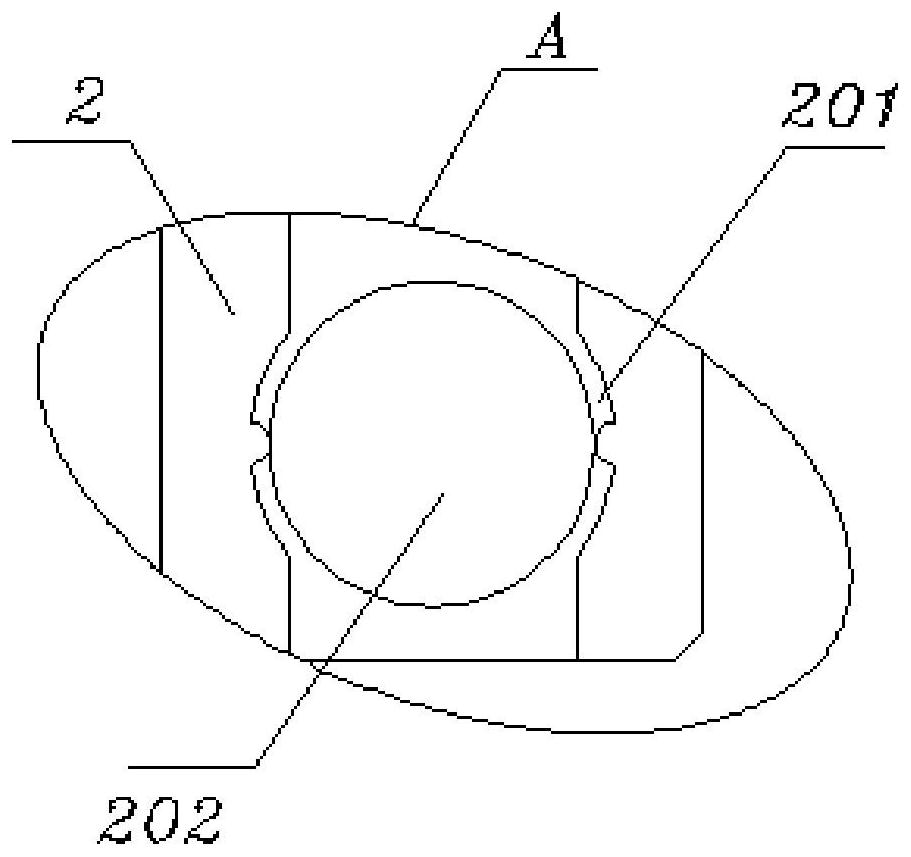

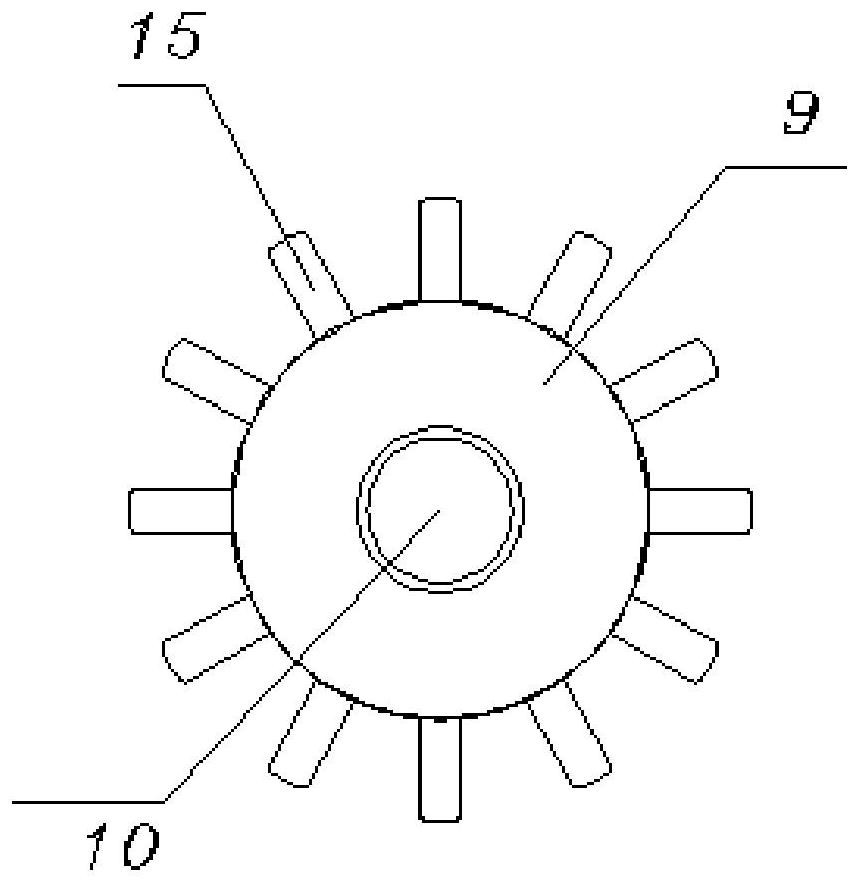

Method used

Image

Examples

Embodiment 1

[0045] A kind of aromatic amine compound containing polysulfonic acid group, its structural formula is as follows:

[0046]

[0047] The preparation method of polysulfonic acid group-containing aromatic amine compound I-1 comprises the following steps:

[0048] S1: In the reaction equipment, 18.9 g (0.1 mol) of 100% tetraethylene pentamine was dissolved in 200 mL of water, and the temperature was raised to 60° C. with stirring. Dissolve 53.6 g (0.4 mol) of 100% sodium hydroxymethanesulfonate in 300 mL of water. The sodium hydroxymethanesulfonate aqueous solution was added dropwise to the aqueous solution of tetraethylene pentamine in the reaction equipment. After the dropwise addition, the reaction was continued at pH=10 and 60°C for 6 hours. Tetraethylene pentamine reaction solution.

[0049] S2: the polysulfonic acid group-modified tetraethylene pentamine reaction solution obtained in step S1 is heated to 70-75° C., and 22.3 g (0.12 mol) of 100% p-nitrobenzoyl chloride ...

Embodiment 2

[0054] The difference from Example 1 is that:

[0055] A kind of aromatic amine compound containing polysulfonic acid group, its structural formula is as follows:

[0056]

[0057] The preparation method of polysulfonic acid group-containing aromatic amine compound I-2 comprises the following steps:

[0058] S1: Dissolve 18.9 g (0.1 mol) of 100% tetraethylene pentamine in 200 mL of water, and raise the temperature to 60° C. with stirring. Dissolve 53.6 g (0.4 mol) of 100% sodium hydroxymethanesulfonate in 300 mL of water. The sodium hydroxymethanesulfonate aqueous solution was added dropwise to the aqueous solution of tetraethylenepentamine. After the dropwise addition, the reaction was continued at pH=10 and 60°C for 6 hours. Amine reaction solution.

[0059] S2: the polysulfonic acid group-modified tetraethylene pentamine reaction solution obtained in step S1 is heated to 80-85° C., and 24.3 g (0.12 mol) of 100% 2,4-dinitrochlorobenzene is slowly added. The time is ab...

Embodiment 3

[0062] The difference from Example 1 is that:

[0063] A kind of aromatic amine compound containing polysulfonic acid group, its structural formula is as follows:

[0064]

[0065] The preparation method of polysulfonic acid group-containing aromatic amine compound I-3 comprises the following steps:

[0066] S1: Dissolve 18.9 g (0.1 mol) of 100% tetraethylene pentamine in 200 mL of water, and raise the temperature to 60° C. with stirring. Dissolve 64.0 g (0.4 mol) of 100% sodium glycidyl sulfonate in 300 mL of water. The aqueous solution of sodium glycidyl sulfonate was added dropwise to the aqueous solution of tetraethylene pentamine. After the dropwise addition, the reaction was continued at pH=10 and 60°C for 6 hours. Pentaamine reaction solution.

[0067]S2: the polysulfonic acid group-modified tetraethylene pentamine reaction solution obtained in step S1 is heated to 70-75° C., and 26.6 g (0.12 mol) of p-nitrobenzenesulfonyl chloride (100%) is slowly added, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com