Environment-friendly fabric core conveyor belt adhesive tape and preparation method thereof

An environmentally friendly, conveyor belt technology, applied in the direction of adhesives, adhesive types, recycled rubber adhesives, etc., can solve the problems of endangering the health of employees, waste of resources, pollution of the environment, etc., and achieve the effect of saving raw material costs and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

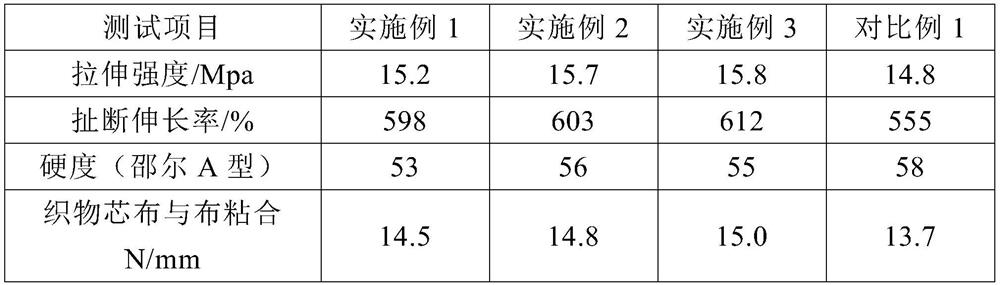

Examples

Embodiment 1

[0027] A kind of preparation method of environment-friendly fabric core conveyor belt glue, the steps by weight are:

[0028] (1) Plasticizing: Pass 50 parts of natural rubber on an open mill, the roll distance of the mill is 1.2mm, the roll temperature is kept at 65°C, and the roll is passed for 4 minutes, and then 50 parts of styrene-butadiene rubber and 10 parts of environmental protection are added. Type reclaimed rubber is mixed together, and the film is unloaded after passing the roller for 4 minutes;

[0029] (2) One-stage mixing: Add the rubber uniformly mixed in step (1) into the internal mixer, mix for 45s, the mixing temperature is 103°C, and the rotor speed is 58r / min; then add 3 parts of zinc oxide, 1 part of Stearic acid, 1 part of antioxidant 4010NA, 0.5 part of antioxidant RD, 0.5 part of antioxidant BLE, 1 part of C5 resin, 5 parts of environmentally friendly aromatic oil, 1 part of modified RS resin, mixed for 50s, then added 10 parts of white carbon Black a...

Embodiment 2

[0032] A kind of preparation method of environment-friendly fabric core conveyor belt glue, the steps by weight are:

[0033] (1) Plasticizing: Pass 60 parts of natural rubber on an open mill, the roll distance of the mill is 1.3mm, the roll temperature is kept at 69°C, and the roll is passed for 3.5 minutes, and then 40 parts of styrene-butadiene rubber and 20 parts of environmental protection are added. Type reclaimed rubber is mixed together, and the film is unloaded after passing the roller for 3 minutes;

[0034] (2) One-stage mixing: add the rubber uniformly mixed in step (1) into the internal mixer, mix for 48s, the mixing temperature is 101°C, and the rotor speed is 60r / min; then 4 parts of zinc oxide, 2 parts of Stearic acid, 1 part of antioxidant RD, 1 part of antioxidant 4020, 1.5 parts of antioxidant BLE, 3 parts of C5 resin, 10 parts of environmentally friendly aromatic oil, 2 parts of modified RS resin, mixed for 53s, then added 15 parts of white carbon Black, 1...

Embodiment 3

[0037] A preparation method of conveyor belt covering rubber containing environmentally friendly high-strength reclaimed rubber, the steps in parts by weight are:

[0038] (1) Plasticizing: 70 parts of natural rubber are rolled on the open mill, the roll distance of the open mill is 1.5mm, the roll temperature is kept at 73 ° C, and the roll is passed for 4 minutes, and then 30 parts of styrene-butadiene rubber and 30 parts of environmental protection are added. Type reclaimed rubber is mixed together, and the film is unloaded after passing the roller for 4 minutes;

[0039](2) One-stage mixing: Add the rubber uniformly mixed in step (1) into the internal mixer, mix for 42s, the mixing temperature is 103°C, and the rotor speed is 54r / min; then add 5 parts of zinc oxide, 3 parts of Stearic acid, 1.5 parts of antioxidant RD, 2 parts of antioxidant 4020, 1.5 parts of antioxidant BLE, 5 parts of C5 resin, 20 parts of environmentally friendly aromatic oil, 3 parts of modified RS re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com