Fermentation tank for margarya melanioides rice noodle acid material

A technology of snail powder and fermenter, which is applied to specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, sterilization method, etc., which can solve the problem of loose gas discharge, browning of capers, and reduction of acidity. The effect of reducing the fermentation effect of raw materials and other issues, to achieve the effect of inhibiting internal gas leakage, inhibiting local browning, and increasing the effect of removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

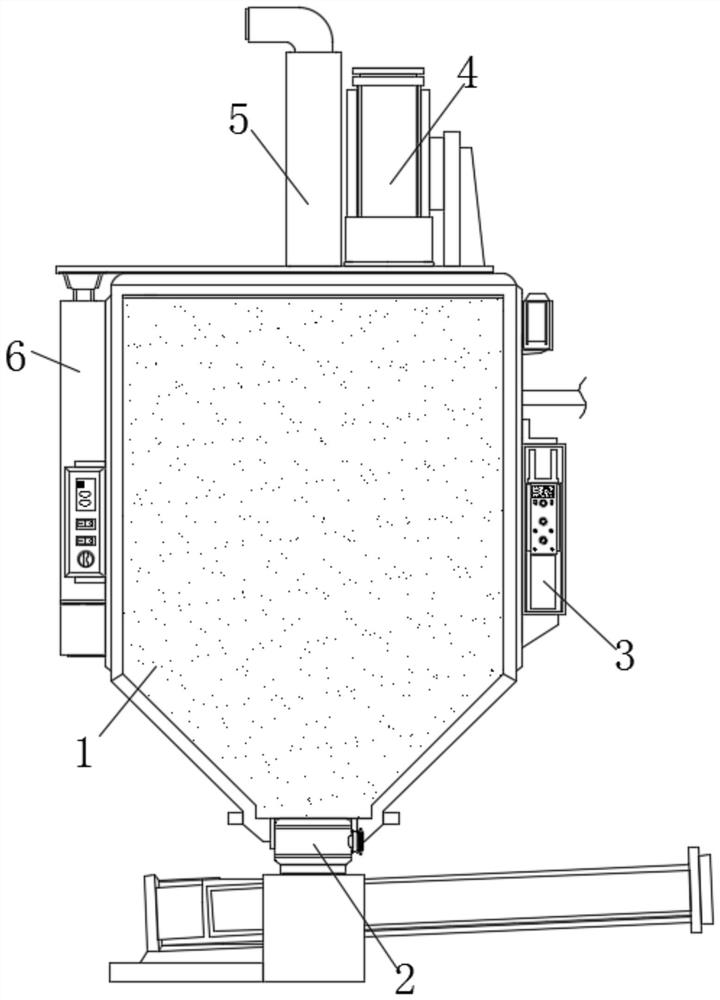

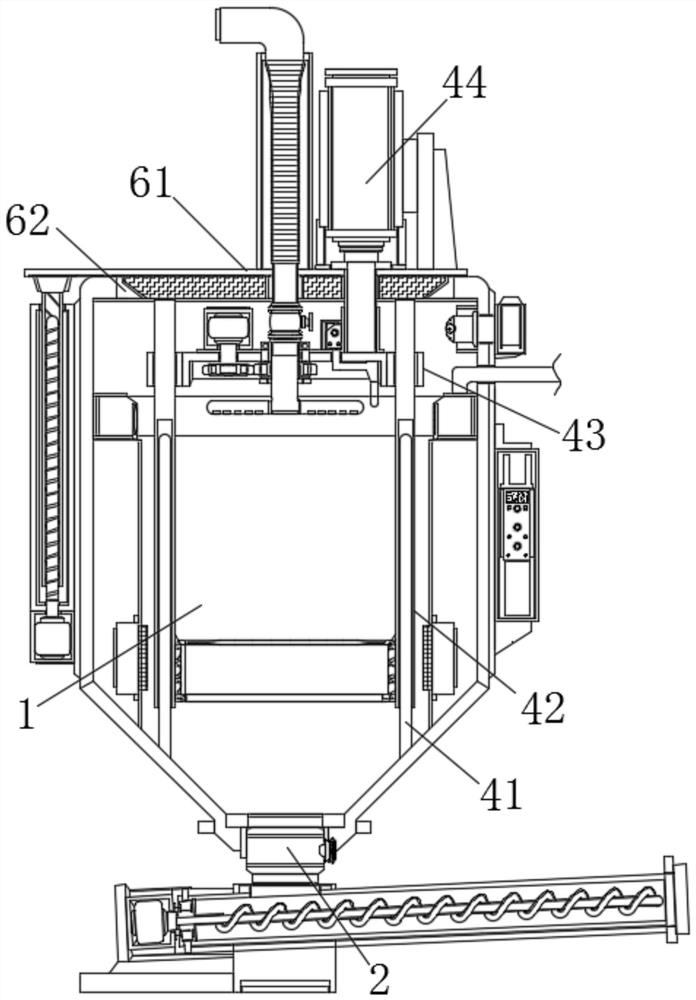

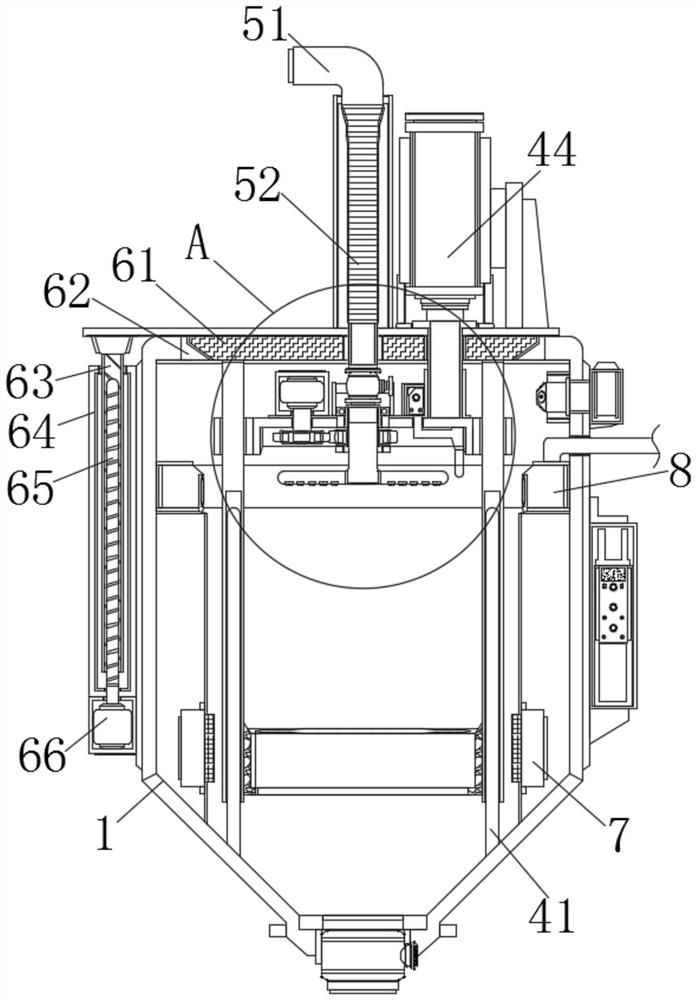

[0040] Example 1, as Figure 1-3 As shown, when the top cover 61 is lifted as a whole, the two sets of connected sleeves 42 can be driven to rise under the limit of the guide post 41, and the annular filter can be driven by the sleeves 42 to rise together on the same level of the water supply device 8. At this time, when the acid material is put in, the water supply channel of the water supply device 8 and the annular groove can be combined, so that the water liquid can be sprayed evenly from the multiple groups of water spray holes, and the cold water can be sprinkled from the ring filter to the surface of the falling acid material. , and then make the cold water to wet the surface of the acid material in advance, and then use two sets of heating devices 7 to heat the immersed solution to a specified temperature, so as to soak and ferment the acid material.

Embodiment 2

[0041] Example 2, as Figure 2-4 As shown, after the acid material is fermented, the air suction pump 53 can be activated to cooperate with the communication between the air guide pipe 55 and the air suction pipe 56 to absorb the fermented gas inside the tank 1, and at the same time, the drive motor 58 drives the structure of the gear set 57. Under the connection, let the air guide pipe 55 and the two groups of air extraction pipes 56 rotate, improve the extraction efficiency of the fermentation gas inside the tank 1, and promote the uniform circulation of the gas from the passage of the telescopic hose 52 and the exhaust pipe 51, so that the fermentation gas can be easily discharged. It is collected at the designated location, which is convenient for direct air purification and increases the environmental protection of the device. The fermented acid material in the tank 1 can be fed into the screw feeder by the activation of the discharge valve, so that the acid can be dischar...

Embodiment 3

[0042] Example 3, as Figure 1-3 As shown, the temperature and acidity of nitrite, nitrate, hydrogen sulfide, formaldehyde fermented inside the tank 1 can be intelligently monitored through the temperature sensor above the tank 1 and the acidity detector installed above the mounting seat 45, so as to improve the The precision of internal mixing and mixing can be controlled by a timer, and the fermentation time and timing function can be automatically set to automatically add beans, radishes and bamboo shoots, etc. further improvement.

[0043] Working principle: When the device is in use, through the control of the control panel 3, the servo motor 66 can be started to drive the screw rod 65 to rotate, and the internal threaded pipe 63 is forced to rise with the rotation of the screw rod 65, and then the internal threaded pipe 63 is used. The top cover 61 is lifted up, and the sealing engagement between the top cover 61 and the port 62 is cancelled. At this time, the acid mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com