Tetragenococcus halophilus subsp. Halophilus and application thereof

A technology of tetradococcus halophilus and subspecies, which is applied in the field of tetradococcus halophilus halophilus subspecies, which can solve the problem of anaerobic fermented mash fermentation environment, high fermentation salinity, and biogenic amine degradation strains that are difficult for sauce and soy sauce Production process and other issues, to achieve the effect of excellent flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] According to a typical embodiment of the present invention, the application of the strain SP101 includes: mixing the koji and salt water to make a mash, inoculating the strain SP101 into the fermented mash for 0 to 15 days for soy sauce or brewing sauce production and fermentation, and the inoculation amount is 10 6 ~10 7 pcs / g mash.

[0027] Inoculation of Tetraphylococcus halophila subsp. halophila during the fermentation of sauce and soy sauce T. halophilus subsp. Halophilus SP101 (ie SP101 in the deposit survival certificate, Tetraphylococcus halophilus Tetragenococcus halophilus), without changing the original fermentation control process, the strain can inhibit the growth and metabolism of amine-producing bacteria in the mash, significantly reduce the biogenic amine content of soy sauce and soy sauce, and endow soybean paste and soy sauce with excellent flavor. Preferably, the production and fermentation of soy sauce includes: the fermentation temperatu...

Embodiment 1

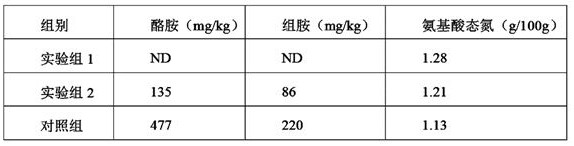

[0038] The effect of strain SP101 on reducing biogenic amines in soy sauce

[0039] Tetraphylococcus halophila subsp. halophila T. halophilus subsp. Halophilus After SP101 was activated and cultured, the inoculation amount was 10 6 Pieces / g of soy sauce mash were inoculated into the fermented soy sauce mash for 0 days (the sauce mash was mixed with koji and 17% brine in a weight ratio of 1:1.5), as experimental group 1, Tetrahydricococcus halophilus halophilic sub- kind T. halophilus subsp. Halophilus After SP102 was activated and cultured, the inoculation amount was 10 6 Pieces / g of mash were inoculated into the same batch of fermented mash for 0 days as experimental group 2; the same batch of 0-day mash without SP101 was used as the control group. Both the experimental group and the control group were controlled according to the conventional fermentation process of high-salt dilute soy sauce (the fermentation temperature in the early stage was 8~10°C, and the ferm...

Embodiment 2

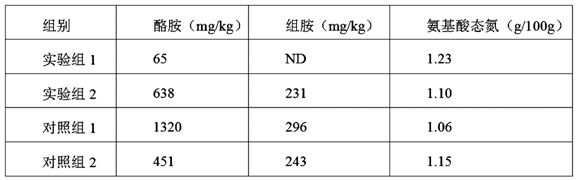

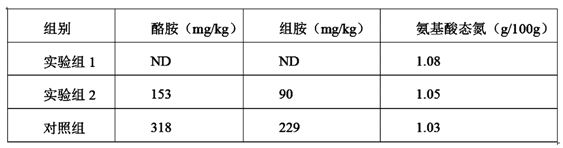

[0044] Inhibitory effect of strain SP101 on amine-producing bacteria in soy sauce mash

[0045] Take the high-salt dilute soy sauce mash (the same as the soy sauce mash of Example 1) that has been fermented for 0 days, and the amine-producing bacteria (Tetraphylococcus halophilus subsp. T. halophilus subsp. Halophilus SP133) and Tetraphylococcus halophilus subsp. T. halophilus subsp. Halophilus SP101 were activated and cultured separately, first inoculated with amine-producing bacteria, and the inoculation amount was 10 4 ~10 5 Pieces / g soy mash, and then inoculated with SP101, the inoculation amount is 10 6 Pieces / g sauce mash, as experimental group 1; inoculate amine-producing bacteria first, and the inoculation amount is 10 4 ~10 5 Pieces / g mash, and then inoculated with SP102, the inoculation amount is 10 6 Pieces / g soy mash, as experimental group 2; inoculate only amine-producing bacteria, the inoculation amount is 10 4 ~10 5 The same batch of fermented mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com