Efficient microbial fuel cell integrated air cathode and preparation method and application thereof

A high-efficiency microorganism and fuel cell technology, applied in the direction of biochemical fuel cells, battery electrodes, electrical components, etc., can solve the problems of MFC microbial contamination, complex preparation process, etc., and achieve the effect of low cost, simple preparation and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

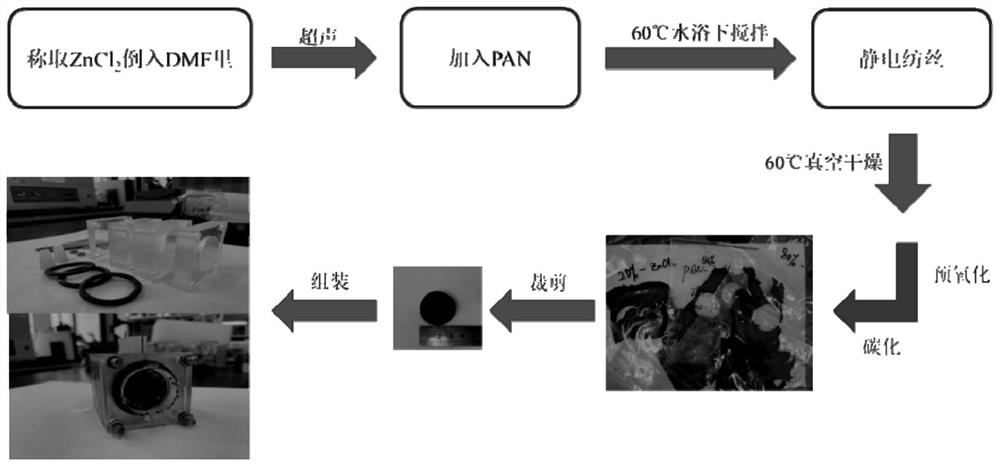

[0020] see figure 1 , a first aspect of the present invention provides a method for preparing a high-efficiency microbial fuel cell integrated air cathode, comprising the following steps:

[0021] S1, adding zinc chloride and polyacrylonitrile (PAN) to N,N-dimethylformamide (DMF) and mixing uniformly to obtain spinning solution;

[0022] S2, electrospinning the spinning solution to obtain a fiber membrane;

[0023] S3, drying the fiber membrane and performing pre-oxidation and high-temperature carbonization in sequence to obtain an integrated air cathode of a high-efficiency microbial fuel cell.

[0024] In the present invention, the dosage ratio of zinc chloride and N,N-dimethylformamide is (0.1-0.4) g: 10 mL.

[0025] In the present invention, the mass ratio of zinc chloride to polyacrylonitrile is (0.1-0.4):1, preferably (0.25-0.3):1, and more preferably 0.3:1.

[0026] In the present invention, the steps of adding zinc chloride and polyacrylonitrile into N,N-dimethylfor...

Embodiment 1

[0034] (1) Weigh 0.1g ZnCl 2 Poured into 10mL N,N-dimethylformamide, ultrasonicated for 2h to obtain ZnCl 2 solution;

[0035] (2) Weigh 1g PAN and add ZnCl 2 In the solution, heat and stir for 6 h in a water bath at 60 °C until the mixture is uniform and the solution becomes translucent to obtain ZnCl 2 / PAN solution;

[0036] (3) ZnCl 2 / PAN solution is poured into a 50mL syringe, the device is connected, a voltage of 20kV is applied, and the ZnCl is injected at a rate of 1mL / h. 2 The PAN solution is pushed out from the needle 18cm away from the collecting drum, the drum is collected, and after the spinning solution is consumed, a fiber film is obtained; wherein, the drum diameter is 76.48 mm, the drum speed is 30 mm / s, the nozzle moving speed is 5 mm / s, and the reciprocating The distance is 75mm;

[0037] (4) The fiber membrane was dried in a vacuum drying oven at 60°C for 12h, then pre-oxidized in an oven at 250°C for 2h, and finally the sample was heated in a tube f...

Embodiment 2

[0039] (1) Weigh 0.25g ZnCl 2 Poured into 10mL N,N-dimethylformamide, ultrasonicated for 2h to obtain ZnCl 2 solution;

[0040] (2) Weigh 1g PAN and add ZnCl 2 In the solution, heat and stir for 6 h in a water bath at 60 °C until the mixture is uniform and the solution becomes translucent to obtain ZnCl 2 / PAN solution;

[0041] (3) ZnCl 2 / PAN solution is poured into a 50mL syringe, the device is connected, a voltage of 20kV is applied, and the ZnCl is injected at a rate of 1mL / h. 2 The PAN solution is pushed out from the needle 18cm away from the collecting drum, the drum is collected, and after the spinning solution is consumed, a fiber film is obtained; wherein, the drum diameter is 76.48 mm, the drum speed is 30 mm / s, the nozzle moving speed is 5 mm / s, and the reciprocating The distance is 75mm;

[0042](4) The fiber membrane was dried in a vacuum drying oven at 60°C for 12h, then pre-oxidized in an oven at 250°C for 2h, and finally the sample was heated in a tube f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com