Grinding process for inner ring of knuckle bearing

A joint bearing and inner ring technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve problems such as large gaps, loss of lubrication ability of liners, and seizure of related mechanisms, so as to achieve short processing cycle and improved Working conditions and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

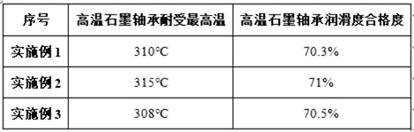

Embodiment 1

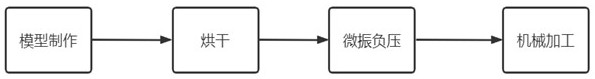

[0042] In this embodiment, the grinding process of the inner ring of the spherical plain bearing with the characteristics of metal bearing and self-lubricating characteristics is as follows:

[0043] (1) Model making: the molding material is selected from polystyrene foam board or expandable polystyrene resin beads, and the density is 10g / dm 3 ; Drill a hole 0.2mm smaller than the diameter of the graphite rod on the lost foam model, and install a graphite rod 2mm longer than the wall thickness of the pattern;

[0044] (2) After the graphite rod is installed, the special lost foam coating for copper alloy is painted, the thickness of the coating is controlled at 0.5mm, and the drying room is dried at below 50°C;

[0045] (3) Connect the model after drying with EPS foam runner;

[0046] (4) Put the assembled model in the lost foam sand box, and evenly add dry sand to vibrate and tighten; cover the upper part of the sand box with plastic cloth to seal, vacuumize negative pressur...

Embodiment 2

[0050] In this embodiment, the grinding process of the inner ring of the spherical plain bearing with the characteristics of metal bearing and self-lubricating characteristics is as follows:

[0051] (1) Model making: the molding material selects polystyrene foam board or expandable polystyrene resin beads, the density is 18 g / dm 3 ; Drill a hole 0.2mm smaller than the diameter of the graphite rod on the lost foam model, and install a graphite rod 1.5mm longer than the wall thickness of the pattern;

[0052] (2) After the graphite rod is installed, the special lost foam coating for copper alloy is painted, the thickness of the coating is controlled at 0.8mm, and the drying room is dried at below 50°C;

[0053] (3) Connect the model after drying with EPS foam runner;

[0054] (4) Put the assembled model in the lost foam sand box, add dry sand evenly to vibrate and tighten; cover the upper part of the sand box with plastic cloth to seal, vacuumize negative pressure, and pour in...

Embodiment 3

[0058] In this embodiment, the grinding process of the inner ring of the spherical plain bearing with the characteristics of metal bearing and self-lubricating characteristics is as follows:

[0059](1) Model making: select polystyrene foam board or expandable polystyrene resin beads as the molding material, the density is 22 g / dm 3 ; Drill a hole 0.2mm smaller than the diameter of the graphite rod on the lost foam model, and install a graphite rod 1mm longer than the wall thickness of the pattern;

[0060] (2) After the graphite rod is installed, the special lost foam coating for copper alloy is painted, and the thickness of the coating is controlled at 1.0mm, and the drying room is dried at below 50°C;

[0061] (3) Connect the model after drying with EPS foam runner;

[0062] (4) Put the assembled model in the lost foam sand box, add dry sand evenly to vibrate and tighten; cover the upper part of the sand box with plastic cloth to seal, vacuumize negative pressure, and pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com