Transportation system for precast slab components

A transportation system and prefabricated panel technology, which is applied in the direction of unstacking, transportation and packaging, stacking of objects, etc., can solve the problems of threatening the personal safety of drivers, affecting the quality of construction, increasing costs, etc., and achieve the goal of saving transportation resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

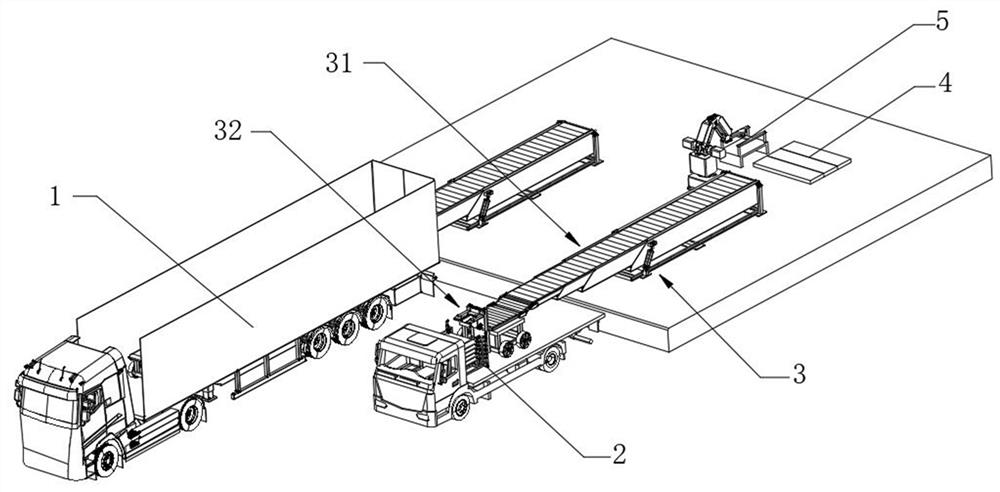

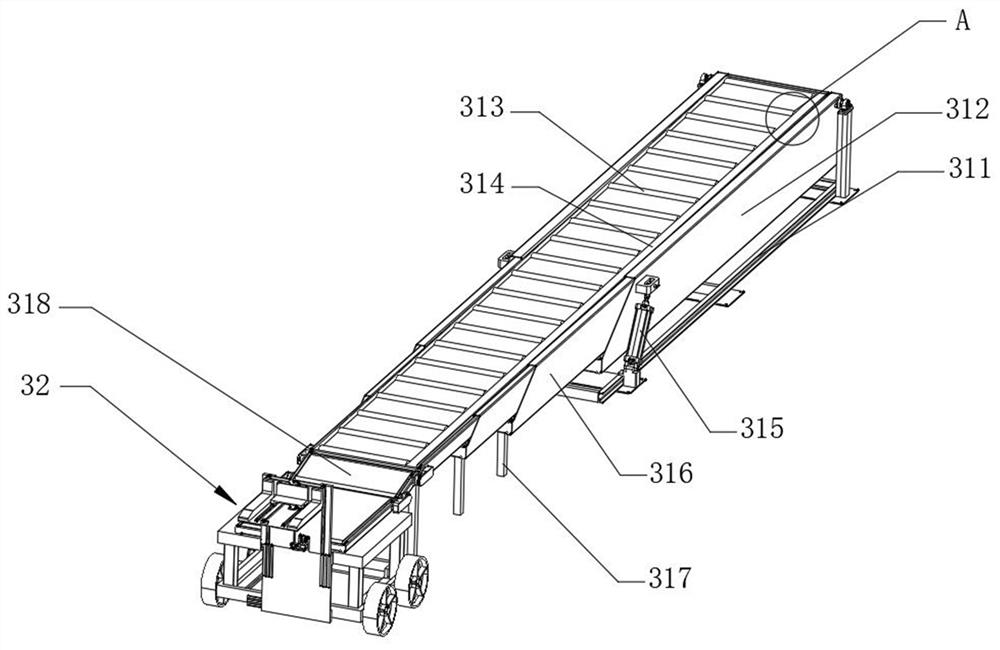

[0031] Please refer to the attached Figure 1~Figure 7 , as shown in the figure, a transportation system for prefabricated panel components, including:

[0032] Transporter 1 for transporting prefabricated panels 4; Transporter 1 is preferably a large freight vehicle;

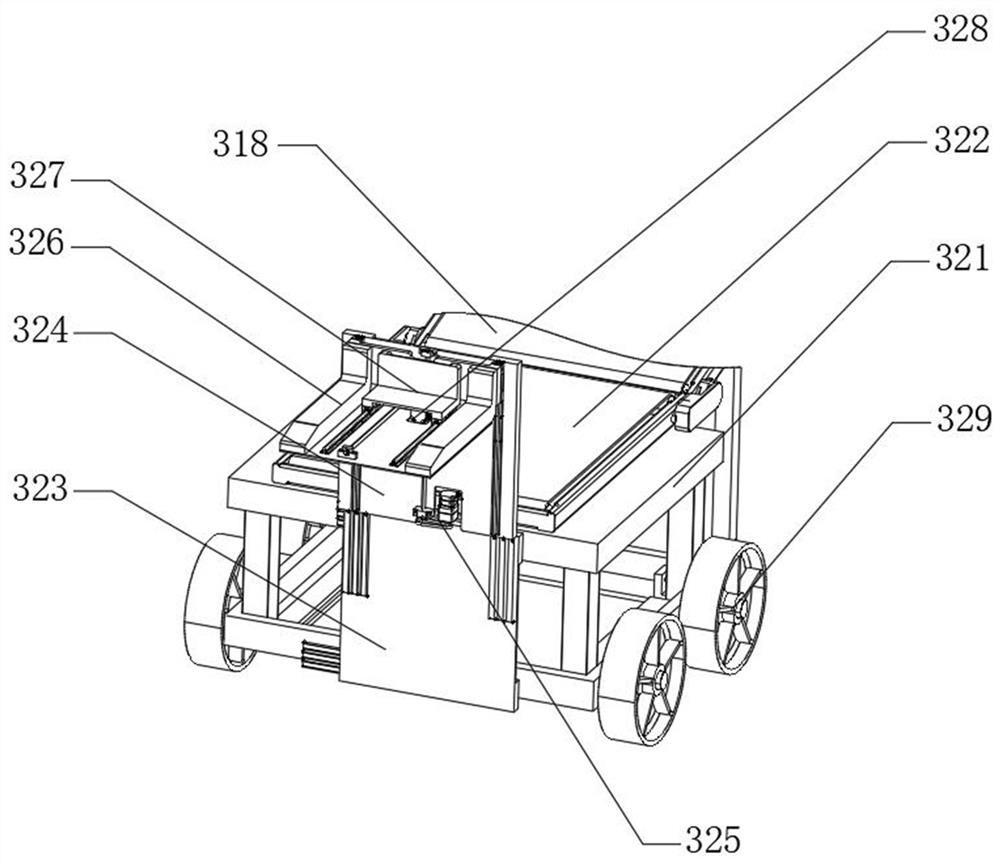

[0033] The transport frame 2 is arranged on the transport vehicle 1 and is used to carry the prefabricated panels 4; the number of the transport frames 2 arranged in the carriage is determined according to the size of the carriage of the transport vehicle 1, but its openings are all facing the carriage door, so as to facilitate the The placing assembly 32 places the prefabricated board 4 on the transport frame 2. When the transport frame 2 in the deepest part of the carriage is full, the folding frame 316 is folded, and then the next empty transport frame 2 is moved into the carriage. In order to facilitate the movement , the bottom of the transport frame 2 is preferably able to install folding wheels;

[003...

Embodiment 2

[0083] This embodiment only describes the part that is different from Embodiment 1, specifically: in order to facilitate the description of this application, the structure of the prefabricated board is described here: as Figure 8 As shown in the figure, a prefabricated panel structure includes a prefabricated bottom plate, and further includes: fixed mesh sheets, trusses, connectors, and thermal insulation and sound insulation formwork. The fixed mesh is fixedly connected to the truss through the connecting piece, and the thermal insulation and sound insulation formwork is arranged on the side of the prefabricated bottom plate. The thermal insulation and sound insulation formwork includes a thermal insulation layer, a polymer cement mortar layer is arranged on both sides of the thermal insulation layer, and a reinforcement mesh is arranged in the polymer cement mortar layer, and the reinforcement mesh is a basalt fiber mesh cloth or fiber material. The thermal insulation lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com