Transparent resin composition, flexible copper-clad plate containing transparent resin composition and application of flexible copper-clad plate

A technology of flexible copper clad laminate and transparent resin, applied in the field of transparent resin composition and flexible copper clad laminate, can solve the problems of inability to obtain transparent conductive materials, decrease in visible light transmittance, increase in reflectivity of adhesive layer, etc., and achieve excellent phase performance. Capacitance and transparency, excellent transparency, good touch stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

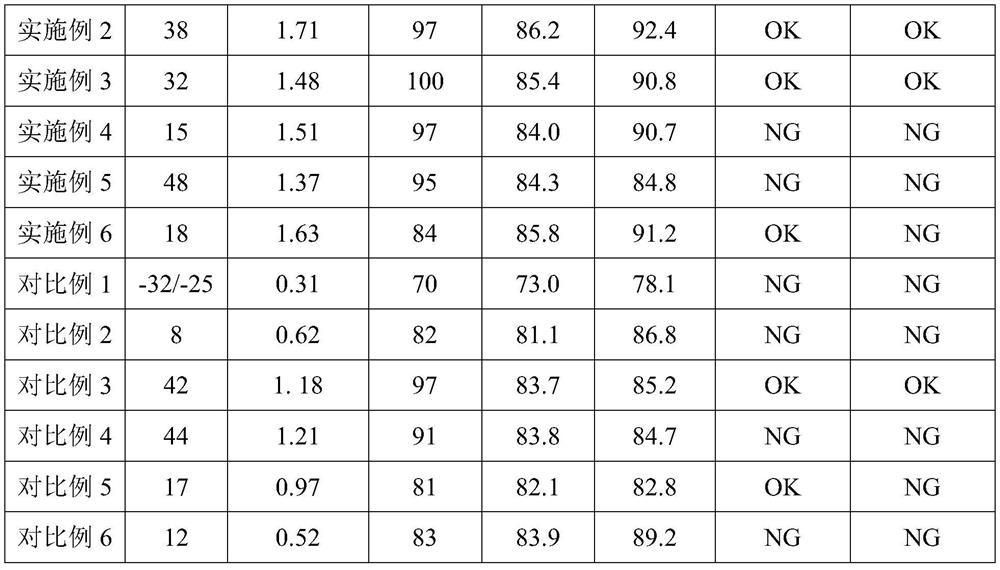

Examples

Embodiment 1

[0073] This embodiment provides a transparent resin composition, comprising the following components in parts by weight: 50 parts of polyacrylate resin (SG-280TEA from Nagase ChemteX, Japan), 20 parts of thermoplastic polyurethane resin (Estane 58271) and novolac epoxy resin 2 parts of resin.

[0074] This embodiment also provides a flexible copper clad laminate, comprising a base film (PET film, 100 μm), a resin layer (5 μm) and a copper foil (2 μm) arranged in sequence; the preparation method is as follows:

[0075] (1) The transparent resin composition described in this embodiment is mixed with methyl ethyl ketone and dispersed uniformly to obtain a resin glue solution with a solid content of 40%;

[0076] (2) Coating the resin glue obtained in step (1) on the surface of the PET film, drying at 80°C for 2 minutes; then compounding with copper foil at 70°C, and curing at 80°C for 5 hours to obtain the Flexible CCL.

Embodiment 2

[0078] This embodiment provides a transparent resin composition, which includes the following components in parts by weight: 65 parts of polyacrylate resin (SG-600TEA from Nagase ChemteX, Japan), 30 parts of thermoplastic polyurethane resin (Estane 58271) and bisphenol A type 3 parts of novolac epoxy resin.

[0079] This embodiment also provides a flexible copper clad laminate, including a base film (PEN film, 200 μm), a resin layer (15 μm) and a copper foil (6 μm) arranged in sequence; the preparation method is as follows:

[0080] (1) The transparent resin composition described in this embodiment is mixed with toluene and dispersed uniformly to obtain a resin glue with a solid content of 50%;

[0081] (2) Coating the resin glue obtained in step (1) on the surface of the PEN film, drying at 100°C for 5 minutes; then compounding with copper foil at 90°C, and then curing at 100°C for 3 hours to obtain the Flexible CCL.

Embodiment 3

[0083] This embodiment provides a transparent resin composition, which includes the following components in parts by weight: 80 parts of polyacrylate resin (SG-790 from Nagase ChemteX, Japan), 40 parts of thermoplastic polyurethane resin (Estane 58271) and o-cresol type 5 parts of novolac epoxy resin.

[0084] This embodiment also provides a flexible copper clad laminate, comprising a base film (CPI film, 50 μm), a resin layer (30 μm) and a copper foil (9 μm) arranged in sequence; the preparation method is as follows:

[0085] (1) The transparent resin composition described in this embodiment is mixed with cyclohexanone and uniformly dispersed to obtain a resin glue with a solid content of 60%;

[0086] (2) Coating the resin glue solution obtained in step (1) on the surface of the CPI film, drying at 120°C for 3 minutes; then compounding with copper foil at 80°C, and then curing at 90°C for 4 hours to obtain the Flexible CCL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com