Automatic yarn splitting system and method on yarn carrier of three-dimensional knitting machine

A knitting machine and yarn carrier technology, which is applied in the directions of knitting, textiles and papermaking, can solve the problems of low automation ability and inability to calculate the length of carbon fiber in real time, and achieve the effect of ensuring the operation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

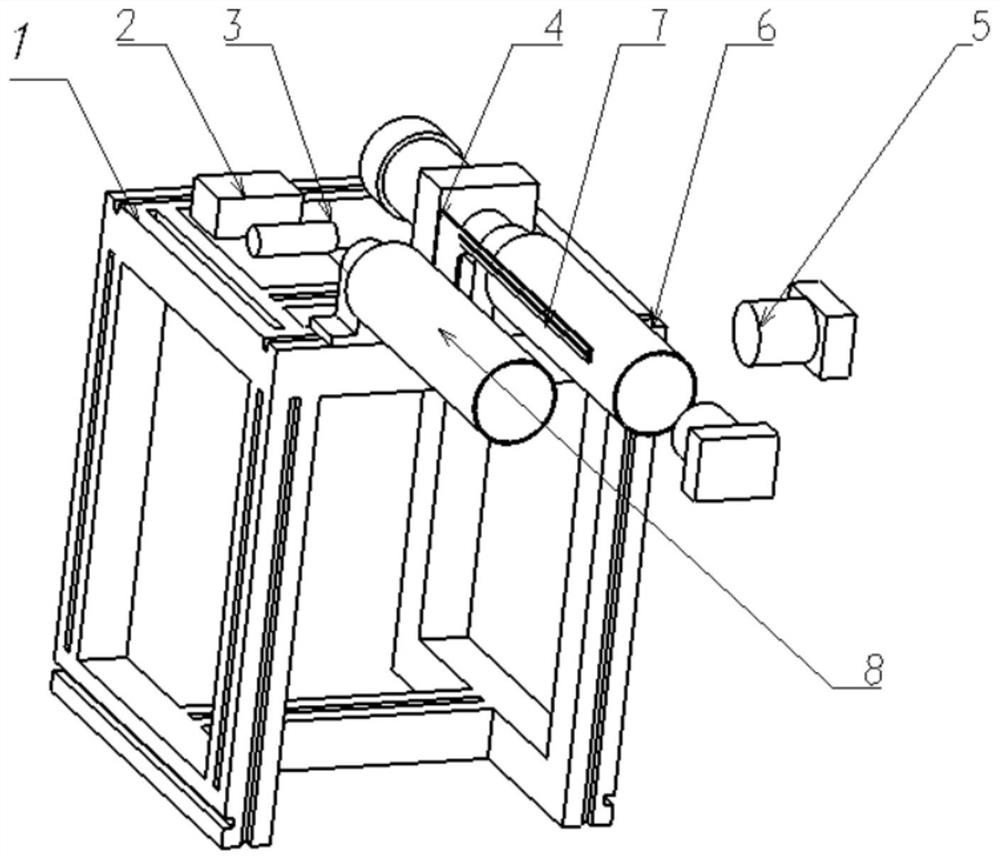

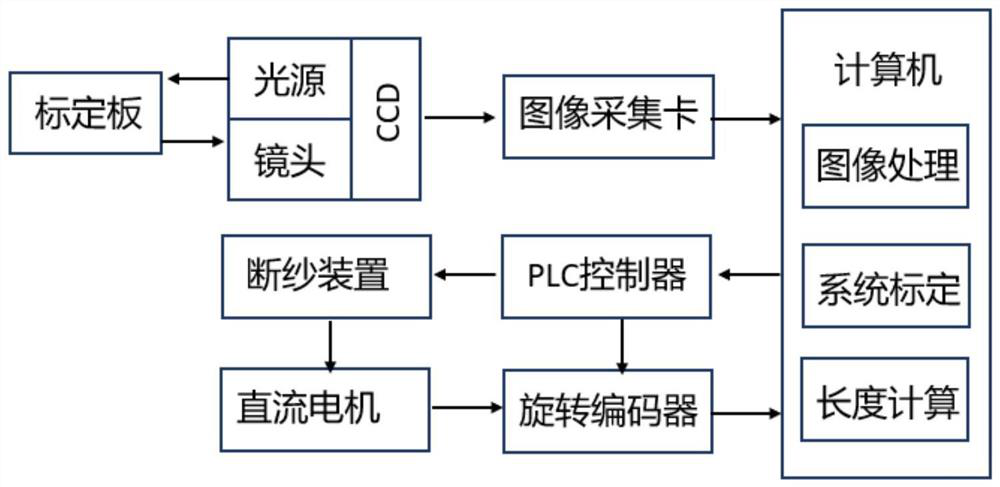

[0024] like figure 1 As shown in the figure, an automatic yarn splitting system for continuous carbon fiber winding with a specified length on the yarn carrier of a three-dimensional braiding machine includes a frame 1, a controller 2, a 1024 encoder 3, a DC motor 4, a visual measurement system 5, an active carrier Yarn bobbin 6, yarn pressing rod 7, driven yarn-carrying bobbin 8, calculation module, yarn breaking device.

[0025] The carbon fiber roll to be divided is clamped on the driven yarn carrying drum 8 through the clamping device, the carbon fiber yarn winding drum is sleeved on the active yarn carrying drum 6, and the carbon fiber is fixed on the yarn drum from the driven yarn carrying drum 8 through the yarn pressing rod 7. On, adjust the yarn pressing rod 7 to the appropriate position, so that the subsequent carbon fiber winding process is smooth and does not increase.

[0026] When the power is turned on, the DC motor rotates 4 to drive the active yarn-carrying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com