Supercritical CO2 combined heat and power generation system and method integrated with multi-stage compression heat pump

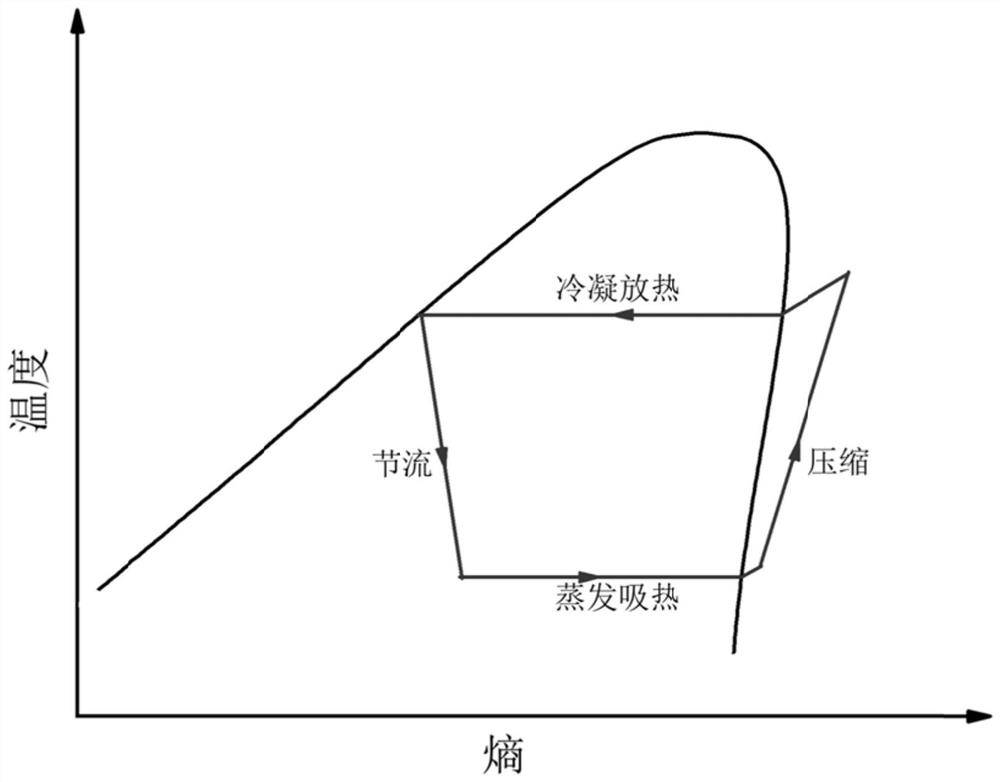

A cogeneration and supercritical technology, which is applied in heat recovery systems, energy-saving heating/cooling, energy industry, etc., can solve the problems of low utilization level of waste heat at the cold end, low COP of heat pump, and increased power consumption of heat pump, so as to improve waste heat The effect of utilization level, improving COP and reducing heat exchange temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are to explain rather than limit the present invention.

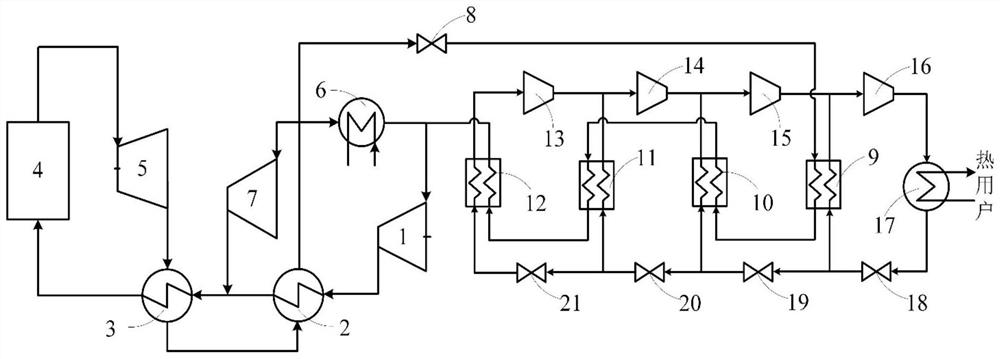

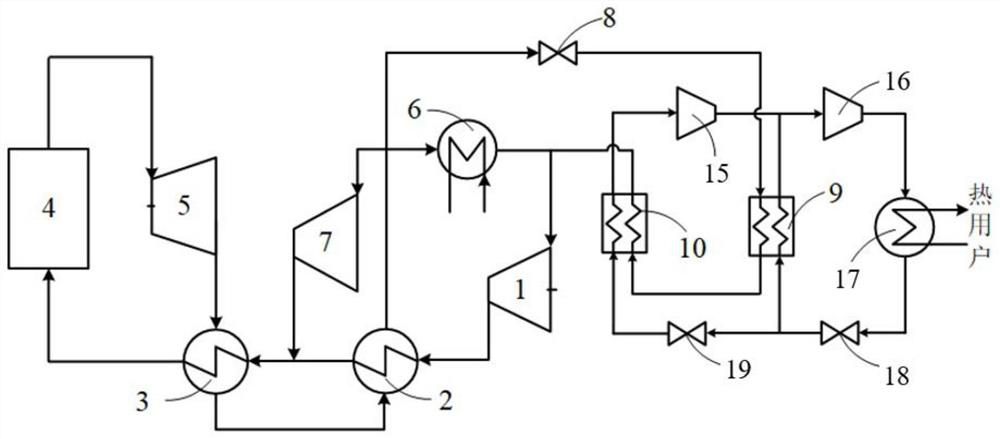

[0027] A Supercritical CO2 Integrated Multistage Compression Heat Pump 2 Combined heat and power systems such as figure 1 As shown, including supercritical carbon dioxide cycle power generation system and heating system; including main compressor 1, low temperature regenerator 2, high temperature regenerator 3, boiler 4, turbine 5, precooler 6, auxiliary compressor 7, Flow regulating valve 8, first stage evaporator 9, second stage evaporator 10, third stage evaporator 11, fourth stage evaporator 12, fourth stage compressor 13, third stage compressor 14, second stage Compressor 15, first stage compressor 16, condenser 17, first stage throttle valve 18, second stage throttle valve 19, third stage throttle valve 20, fourth stage throttle valve 21,

[0028] The supercritical carbon dioxide cycle power gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com