Conductive resin composition for slip prevention and molded article comprising same

A conductive resin and resin molding technology, applied in the field of conductive resin compositions and molded products containing the same, can solve problems such as limitations, and achieve the effects of low surface resistance, improved processability and production efficiency, and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

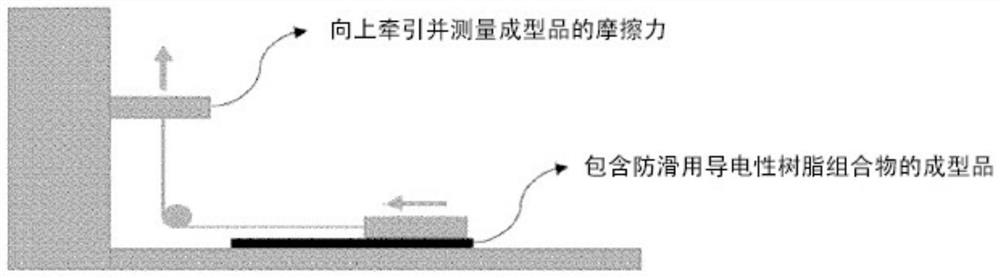

[0031]

[0032] The preparation comprises 100 parts by weight of adhesive resin (80 parts by weight of Hanwha Solutions EVA 1834, 20 parts by weight of Dow Engage 8137POE), 2 parts by weight of carbon nanotubes (CNT), 8 parts by weight of carbon black (carbon black) black), 0.1 parts by weight of antioxidants (hindered phenols), and 0.3 parts by weight of processing aids (fatty acid amides).

[0033] After filling the prepared conductive resin composition for slip resistance in the cavity of a mold, pressurizing it with a press, cooling and solidifying, a molded product (sheet) is produced.

Embodiment 2

[0035] The same procedure as in Example 1 was carried out except that 100 parts by weight of an adhesive resin (20 parts by weight of Hanwha Solutions EVA 1834, 80 parts by weight of Dow Engage 8137POE) were used.

Embodiment 3

[0037] The same procedure as in Example 1 was carried out except that 100 parts by weight of an adhesive resin (20 parts by weight of Hanwha Solutions EVA 1834, 80 parts by weight of Dow FLEXOMER DFDB-9042NT VLDPE) was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com