Urethane resin composition and leather sheet

A technology of urethane and resin composition, applied in textiles and papermaking and other directions, can solve the problem of difficulty in taking into account the stability of the hand feeling and the preparation solution, and achieve the effect of excellent hand feel and the stability of the preparation solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

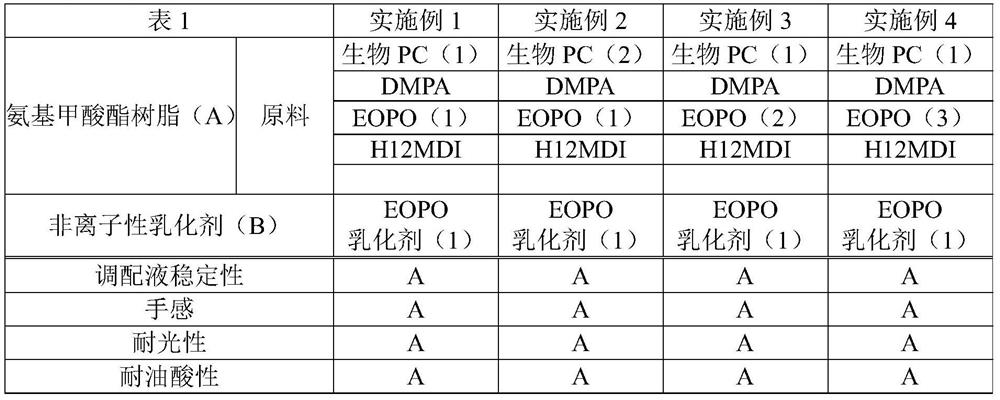

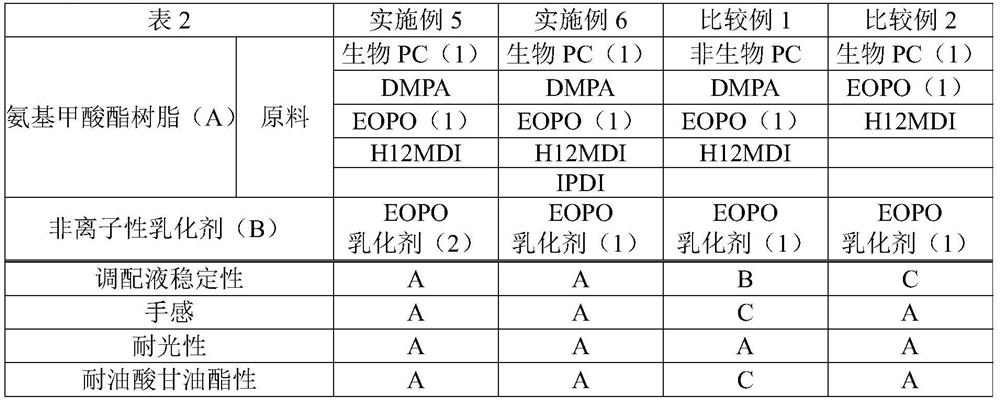

Examples

Embodiment 1

[0061] In a four-necked flask including a stirrer, a reflux cooling tube, a thermometer, and a nitrogen injection tube under a nitrogen gas flow, a biomass-derived polycarbonate polyol ("Beniol ("Beniol ("Beniol) manufactured by Mitsubishi Chemical Co., Ltd.) was added Benebiol)NL-3010DB", 1,4-butanediol and 1,10-decanediol derived from biomass as raw materials, number average molecular weight: 3,000, hereinafter referred to as "bio PC (bio PC) (1) ”) 400 parts by mass, dimethylolpropionic acid (hereinafter referred to as “DMPA”) 6.2 parts by mass, polyoxyethylene polyoxypropylene glycol (number average molecular weight: 1,750, EO / PO=50 / 50, hereinafter referred to as "EOPO(1)") 32 parts by mass and 516 parts by mass of methyl ethyl ketone, after uniform mixing, 78 parts by mass of dicyclohexylmethane diisocyanate (hereinafter referred to as "H12MDI") was added, and then 0.1 part by mass of bismuth octoate was added , react at 70° C. for about 1 hour to obtain a methyl ethyl ke...

Embodiment 2

[0063]In a four-necked flask including a stirrer, a reflux cooling tube, a thermometer, and a nitrogen injection tube under a nitrogen stream, a biomass-derived polycarbonate polyol ("Beniol ("Beniol ("Beniol) manufactured by Mitsubishi Chemical Co., Ltd.) was added. Benebiol)NL-3030DB", 1,4-butanediol and 1,10-decanediol derived from biomass as raw materials, number average molecular weight: 3,000, hereinafter referred to as "bio-PC(2)") 400 mass parts, 6.2 parts by mass of DMPA, 32 parts by mass of EOPO(1), and 516 parts by mass of methyl ethyl ketone. After uniform mixing, 78 parts by mass of H12MDI was added, and then 0.1 part by mass of bismuth octoate was added, and the reaction was carried out at 70° C. for about 1 hour. , to obtain a methyl ethyl ketone solution of urethane polymer. Next, 5 parts by mass of triethylamine and 16 parts by mass of EOPO emulsifier (1) were added to the methyl ethyl ketone solution of the urethane polymer obtained by the method, and mixed, ...

Embodiment 3

[0065] Under nitrogen flow, in a four-necked flask including a stirrer, a reflux cooling tube, a thermometer and a nitrogen injection tube, add 400 parts by mass of biological PC (1), 6.2 parts by mass of DMPA, polyoxyethylene polyoxypropylene glycol (number average Molecular weight: 1,400, EO / PO=75 / 25, hereinafter referred to as “EOPO(2)”) 32 parts by mass, 518 parts by mass of methyl ethyl ketone, after uniform mixing, 80 parts by mass of H12MDI was added, and then 0.1 parts by mass of bismuth octoate was added parts by mass, and reacted at 70° C. for about 1 hour to obtain a methyl ethyl ketone solution of a urethane polymer. Next, 5 parts by mass of triethylamine and 16 parts by mass of EOPO emulsifier (1) were added to the methyl ethyl ketone solution of the urethane polymer obtained by the method, and mixed, and then ion-exchanged water was added. 788 parts by mass, and 7.8 parts by mass of piperazine were added, and then methyl ethyl ketone was distilled off under reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com