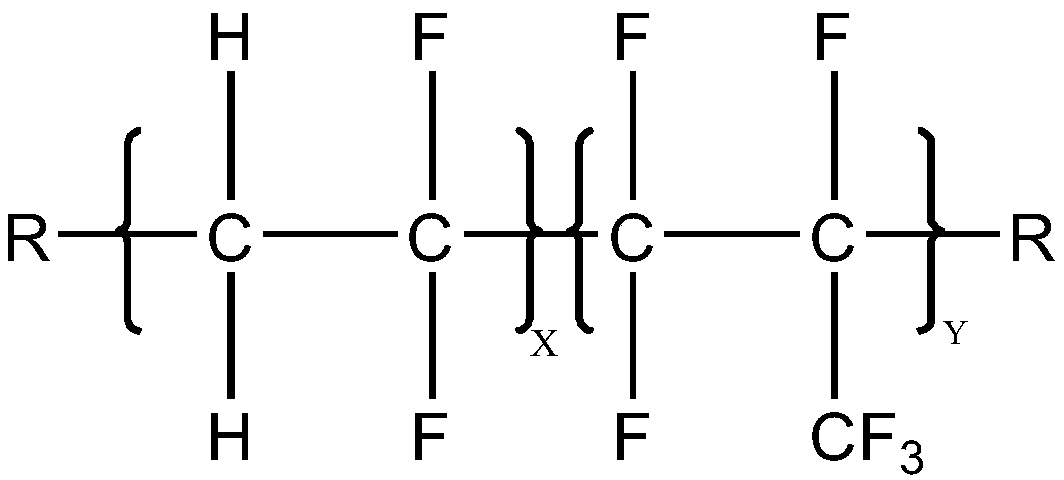

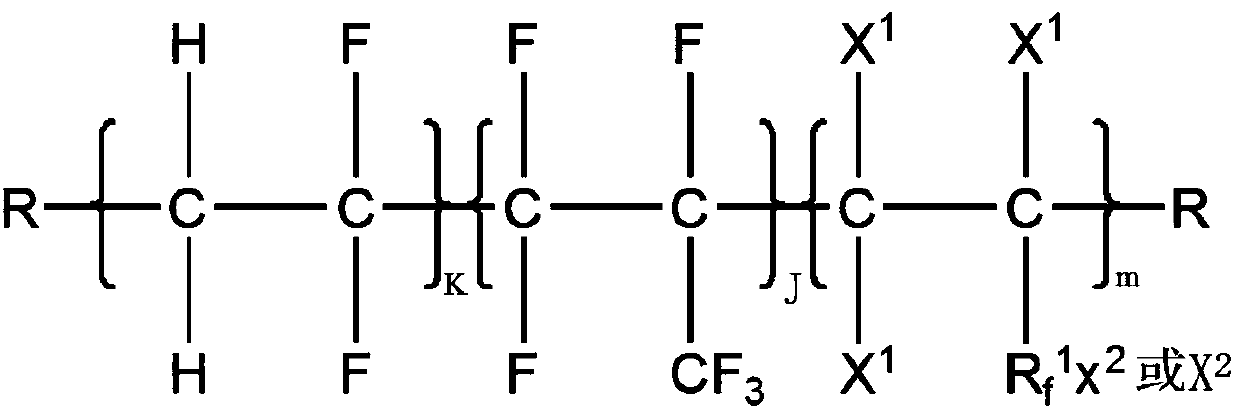

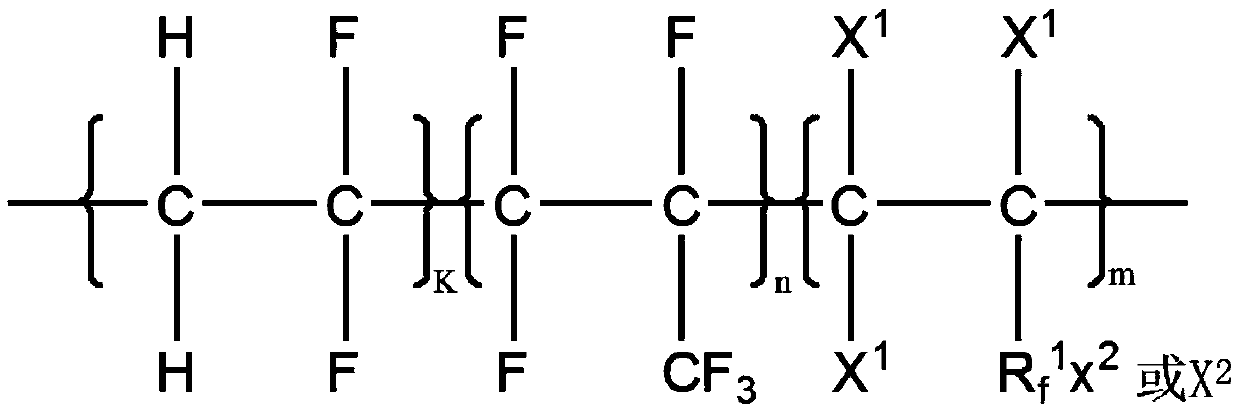

Binary peroxy fluororubber and preparation method thereof, and intelligent wearable material and preparation method thereof

A technology of binary peroxide fluororubber and vinylidene fluoride, which is applied in the field of binary peroxide fluororubber and its preparation, smart wearable wristband and watchband materials and preparation, and can solve the problem of oleic acid resistance that cannot meet the requirements of safety and environmental protection. , durability, physical comfort and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Carried out in a 10L high-pressure polymerization reactor, the total weight of vinylidene fluoride and hexafluoropropylene added in this embodiment is 2.3Kg, and the specific steps are:

[0083] A1, add 5L deionized water, 4g diiodomethane and 10g perfluoropolyether carboxylate ammonium salt (10wt%) in the high-pressure polymerization reactor, evacuate nitrogen replacement, reduce the oxygen content in the high-pressure polymerization reactor to less than 25ppm, And the temperature of the reactor was raised to 85°C;

[0084] A2. Add initial monomers (vinylidene fluoride and hexafluoropropylene) to the high-pressure polymerization reactor with a compressor until the pressure in the high-pressure polymerization reactor is 2.0Mpa, start stirring, and adjust the rotation speed to 98rpm;

[0085] A3, when the mixture in the autoclave polymerization reactor is heated to 90 DEG C, add 4g initiator ammonium persulfate solution (10wt%), start polymerization reaction; The molar p...

Embodiment 2

[0089] This embodiment is carried out in a 10L high-pressure polymerization reactor. The total weight of vinylidene fluoride and hexafluoropropylene added in this embodiment is 2.3Kg. The specific steps are:

[0090] A1, add 5L deionized water, 7g diiodomethane and 11g perfluoropolyether carboxylate ammonium salt (10wt%) in the high-pressure polymerization reactor, evacuate nitrogen replacement, reduce the oxygen content in the high-pressure polymerization reactor to less than 25ppm, And the temperature of the reactor was raised to 80°C;

[0091] A2. Use a compressor to add initial monomers (vinylidene fluoride and hexafluoropropylene) into the high-pressure polymerization reactor until the pressure in the high-pressure polymerization reactor is 2.5Mpa, start stirring, and adjust the rotation speed to 90rpm;

[0092] A3, when the mixture in the autoclave polymerization reactor is heated to 85 ℃, add the initiator ammonium persulfate solution (10wt%) of 4g, start polymerization...

Embodiment 3

[0096] This embodiment is carried out in a 10L high-pressure polymerization reactor. The total weight of vinylidene fluoride and hexafluoropropylene added in this embodiment is 2.3Kg. The specific steps are:

[0097] A1, add 5L deionized water, 5g diiodomethane and 12g perfluoropolyether carboxylate ammonium salt (10wt%) in the high-pressure polymerization reactor, evacuate nitrogen replacement, reduce the oxygen content in the reactor to less than 25ppm, and Reactor temperature rises to 75°C;

[0098] A2. Use a compressor to add initial monomers (vinylidene fluoride and hexafluoropropylene) into the high-pressure polymerization reactor until the pressure in the high-pressure polymerization reactor is 2.0 Mpa, start stirring, and adjust the rotation speed to 108 rpm;

[0099] A3, add 4g ammonium persulfate solution (10wt%) and 4g sodium bisulfite solution (10wt%) respectively when the mixture in the autoclave polymerization reactor is heated to 80 ℃, start polymerization react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com