Blowing and sucking type carbon dioxide adsorption and trapping reaction device

A carbon dioxide and reaction device technology, applied in chemical instruments and methods, separation methods, products, etc., can solve problems such as low efficiency and complex structure, achieve high concentration, simplify system layout, and reduce investment costs and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

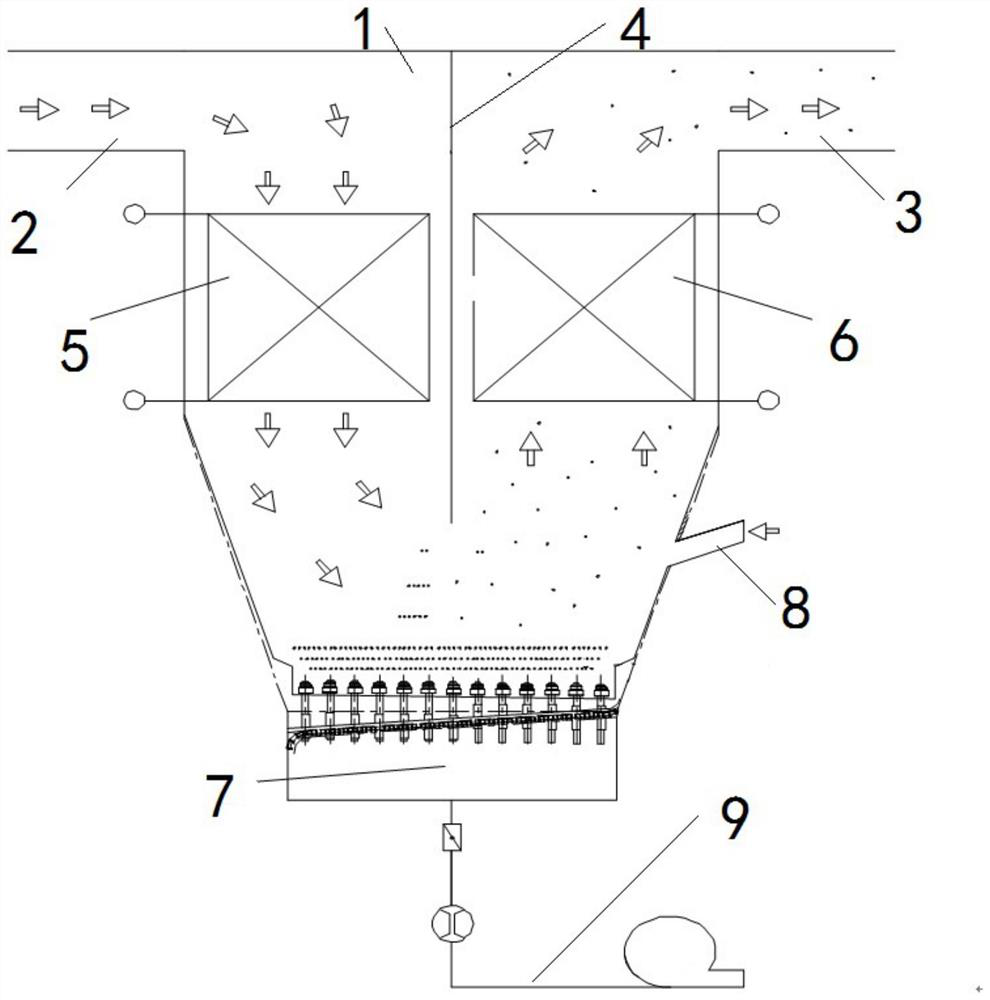

[0027] Embodiment 1: A blowing and suction carbon dioxide adsorption and capture reaction device, which includes a flue gas circulation flue 1, a high-temperature flue gas inlet flue 2, a high-temperature flue gas outlet flue 3, an intermediate partition wall 4, and a front flue. Heat exchanger 5, rear flue heat exchanger 6, air distribution fluidization device 7, carbon dioxide adsorbent supplementary pipeline 8 and fluidized air conveying system 9;

[0028] The flue gas circulation flue 1 is in the shape of a funnel with a seal at the top. The air distribution fluidization device 7 is arranged at the bottom of the flue gas circulation flue 1. The fluidized air conveying system 9 is communicated with the air distribution fluidization device 7. The partition wall 4 is arranged on the inner side of the flue gas circulation flue 1, the top and both ends of the intermediate partition wall 4 are fixedly connected with the flue gas circulation flue 1, and the intermediate partition ...

specific Embodiment approach 2

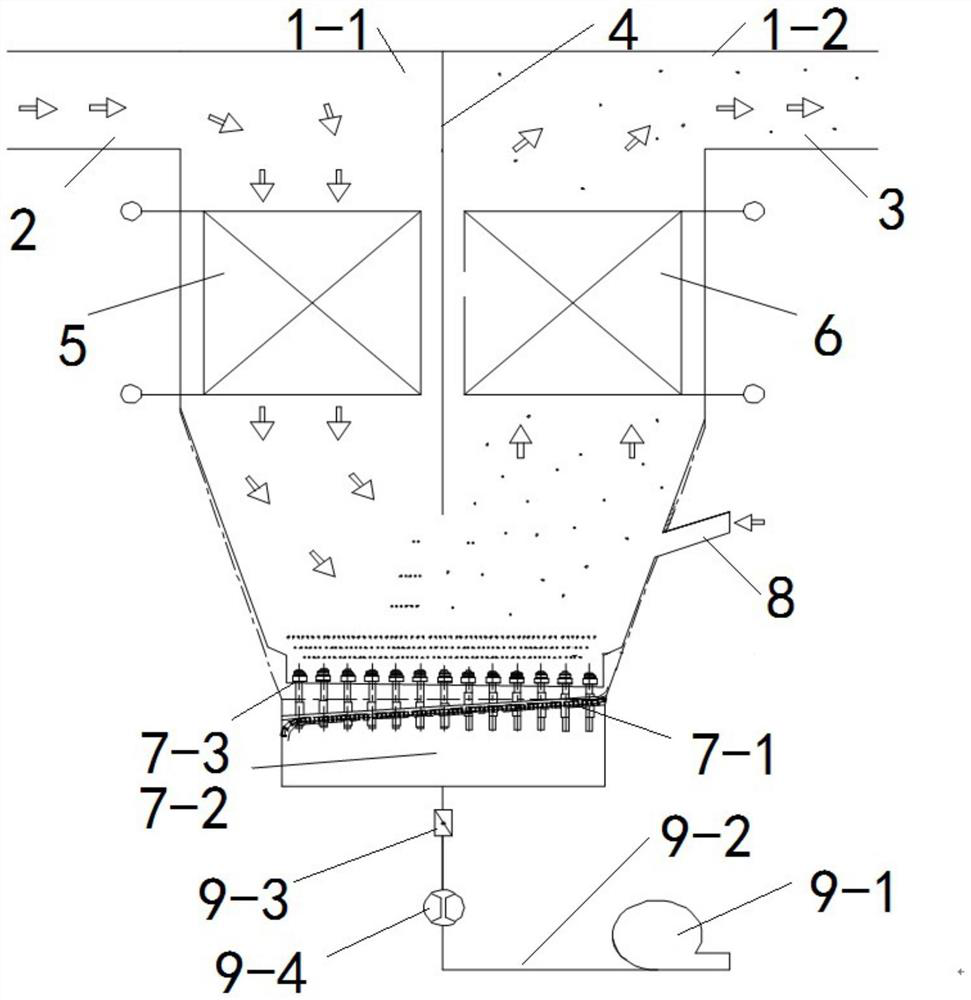

[0030] Embodiment 2: A blow-suction type carbon dioxide adsorption and capture reaction device, the air distribution fluidization device 7 includes an air distribution plate 7-1, a fluidized air chamber 7-2 and a plurality of air caps 7-3;

[0031] The fluidized air chamber 7-2 is fixed at the bottom of the flue gas circulation flue 1, and the bottom of the fluidized air chamber 7-2 is sealed, and the air distribution plate 7-1 is fixed on the fluidized air chamber 7- 2, a plurality of air caps 7-3 are arranged on the air distribution plate 7-1.

[0032] In this embodiment: the air distribution fluidization device is mainly composed of a wind cap and an air distribution plate, the fluidized air chamber provides stable fluidized air for the air distribution plate, and the fluidized air conveying system is composed of a fan, a flow meter and a damper; The outlet chamber is the main capture and reaction area for calcium-based adsorbent to capture carbon dioxide in flue gas.

[0...

specific Embodiment approach 3

[0034] Embodiment 3: A blow-suction type carbon dioxide adsorption and capture reaction device, the fluidized wind conveying system 9 includes a fluidizing fan 9-1 and a conveying pipeline 9-2;

[0035] The inlet end of the conveying pipeline 9-2 is connected with the fluidizing fan 9-1, and the outlet end of the conveying pipeline 9-2 is connected with the bottom of the fluidizing air chamber 7-2.

[0036] Other embodiments are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com