Accurate controlled-release microelement fertilizer and application thereof

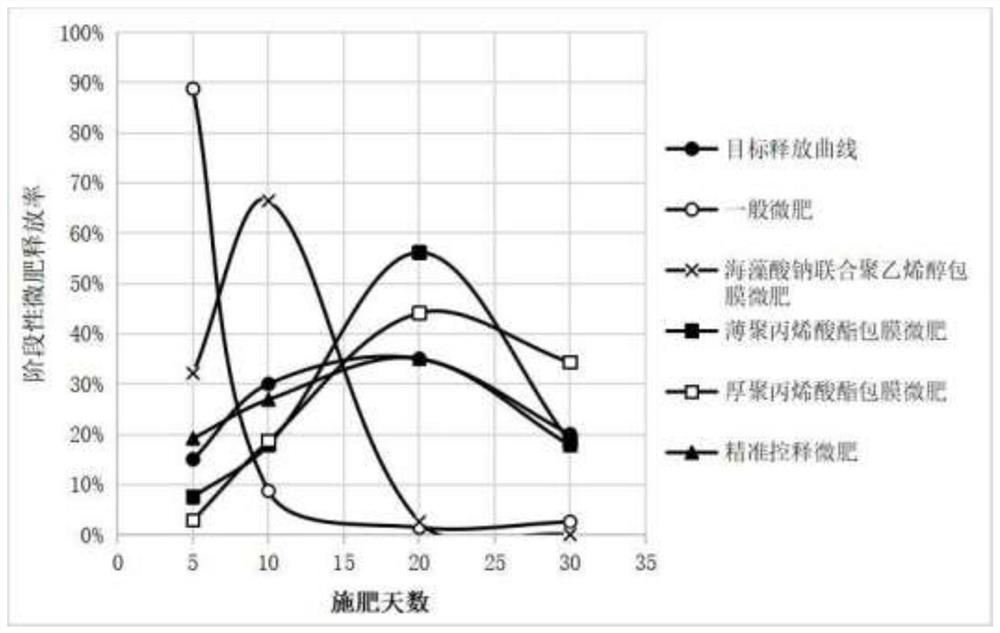

A micro-fertilizer and precise technology, applied in the field of controlled-release fertilizers, can solve the problems of small increase in fertilizer utilization rate, limited micro-fertilizer utilization rate, and difficulty in precise release of fertilizers, so as to improve absorption and utilization rate and meet growth and functional nutrient elements. Precise effect of accumulation and release of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A precise controlled-release micro-fertilizer, comprising the following raw materials and mass percentages: 11% of manganese sulfate monohydrate round particle micro-fertilizer, 39% of thin polyacrylate-coated manganese sulfate monohydrate micro-fertilizer, thick polyacrylate-coated monohydrate Manganese sulfate micro-fertilizer 31%, sodium alginate combined with polyvinyl alcohol-coated manganese sulfate micro-fertilizer 19%.

[0028] The preparation method of the thin polyacrylate-coated manganese sulfate monohydrate micro-fertilizer, comprising the following steps: using the manganese sulfate monohydrate round particle micro-fertilizer with a particle size of 3 mm as the fertilizer core, the fertilizer core and the polyacrylate emulsion in a mass ratio of 5 : 1 ratio to encapsulate, that is.

[0029] The preparation method of the thick polyacrylate-coated manganese sulfate monohydrate micro-fertilizer, comprising the following steps: using the manganese sulfate monoh...

Embodiment 2

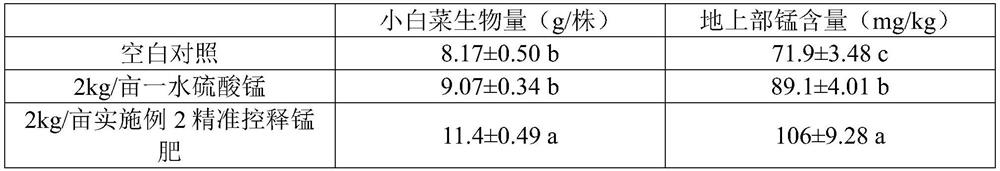

[0036] A precise controlled-release micro-fertilizer, comprising the following raw materials and mass percentages: 10% of manganese sulfate monohydrate round particle micro-fertilizer, 40% of thin polyacrylate-coated manganese sulfate monohydrate micro-fertilizer, and thick polyacrylate-coated monohydrate Manganese sulfate micro-fertilizer 30%, sodium alginate combined with polyvinyl alcohol-coated manganese sulfate micro-fertilizer 20%.

[0037] The preparation method of the thin polyacrylate-coated manganese sulfate monohydrate micro-fertilizer, comprising the following steps: using the manganese sulfate monohydrate round particle micro-fertilizer with a particle size of 3 mm as the fertilizer core, the fertilizer core and the polyacrylate emulsion in a mass ratio of 4 : 1 ratio to encapsulate, that is.

[0038] The preparation method of the thick polyacrylate-coated manganese sulfate monohydrate micro-fertilizer, comprising the following steps: using the manganese sulfate m...

Embodiment 3

[0047] A precise controlled-release micro-fertilizer, comprising the following raw materials and mass percentages: 8% zinc sulfate heptahydrate round particle micro-fertilizer, 38% thin polyacrylate-coated zinc sulfate heptahydrate micro-fertilizer, and thick polyacrylate-coated heptahydrate Zinc sulfate micro-fertilizer 32%, sodium alginate combined with polyvinyl alcohol-coated zinc sulfate micro-fertilizer 22%.

[0048] The preparation method of the thin polyacrylate coated zinc sulfate heptahydrate micro-fertilizer, comprising the following steps: using the zinc sulfate heptahydrate round particle micro-fertilizer with a particle diameter of 3 mm as the fertilizer core, the fertilizer core and the polyacrylate emulsion in a mass ratio of 4 : 1 ratio to encapsulate, that is.

[0049] The preparation method of the thick polyacrylate-coated zinc sulfate heptahydrate micro-fertilizer, comprising the following steps: using the zinc sulfate heptahydrate micro-fertilizer with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com