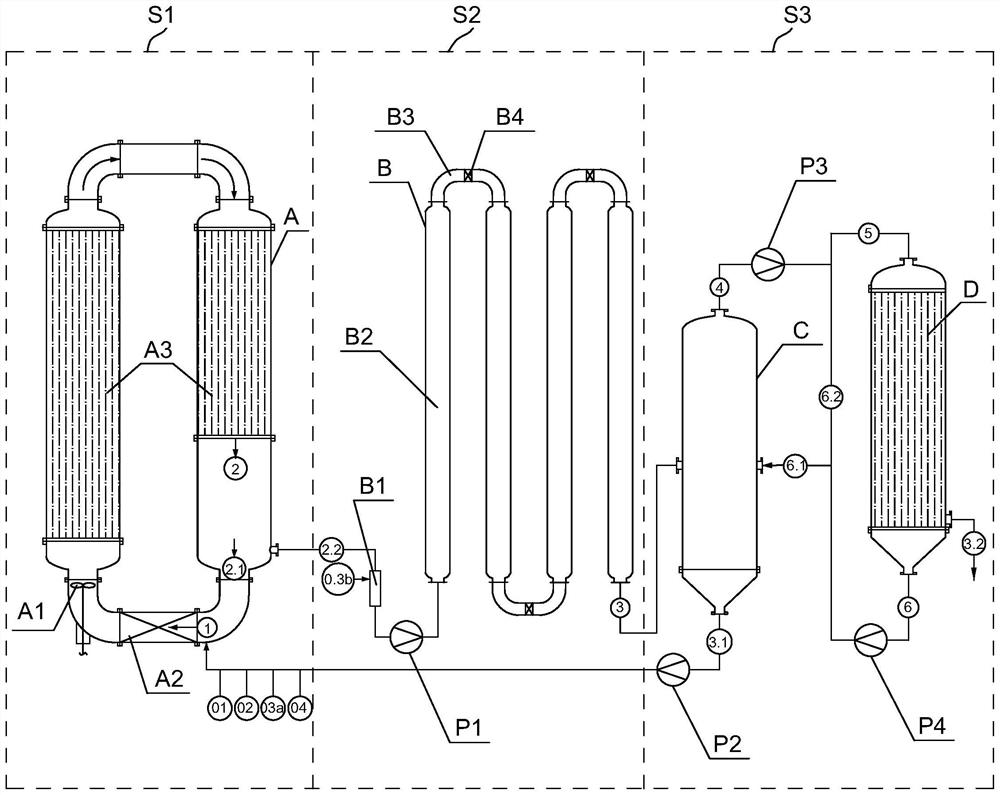

Total mixed flow-plug flow combined cyclohexanone ammoximation process and device

A plug flow, cyclohexanone technology, applied in the chemical industry, oxime preparation, organic chemistry, etc., can solve the problems of slow reaction rate and weak heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

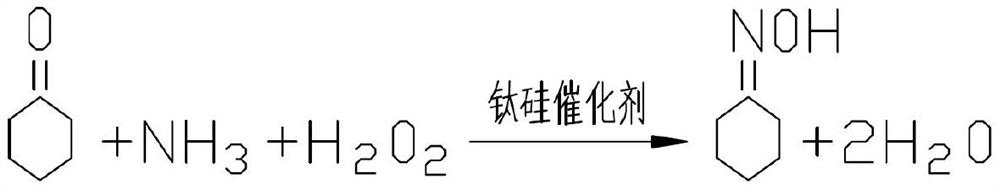

[0055] Raw materials: cyclohexanone, ammonia, aqueous hydrogen peroxide solution (27.5wt.%), titanium-silicon catalyst, no organic solvent;

[0056] The molar ratio of ammonia and cyclohexanone is 2.0, and the molar ratio of hydrogen peroxide and cyclohexanone is 1.07, of which 98.6% is put into S1 and 1.4% is put into S2; Ketone molar ratio 1.5.

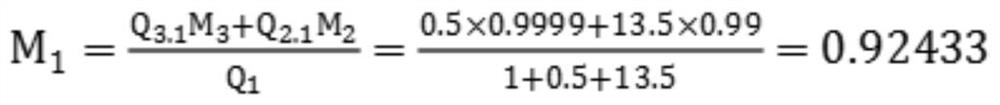

[0057] The total molar flow of cyclohexanone and cyclohexanone oxime of each material is Q, and the conversion rate M of cyclohexanone is defined as the ratio of the moles of cyclohexanone oxime to the total moles of cyclohexanone and cyclohexanone oxime. The cyclohexanone conversion and cyclohexanone oxime selectivity of the post-oximation product are close to 1,

[0058] Control Q with P1 2.2 =1.5Q 01 , then Q 3.1 =0.5Q 01

[0059] Control Q with A1 1 =15Q 01 , then Q 2.1 =Q 2 -Q 2.2 =13.5Q 01

[0060] control M 2 =0.99, M 3 =0.9999, then

[0061]

[0062] After the raw material cyclohexanone enters the pre-ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com