Preparation method of vinyl silicone oil

A technology of vinyl silicone oil and tetramethylammonium hydroxide, which is applied in the field of vinyl silicone oil, can solve the problems of high cost and low yield, and achieve the effects of increasing yield, promoting catalytic activity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

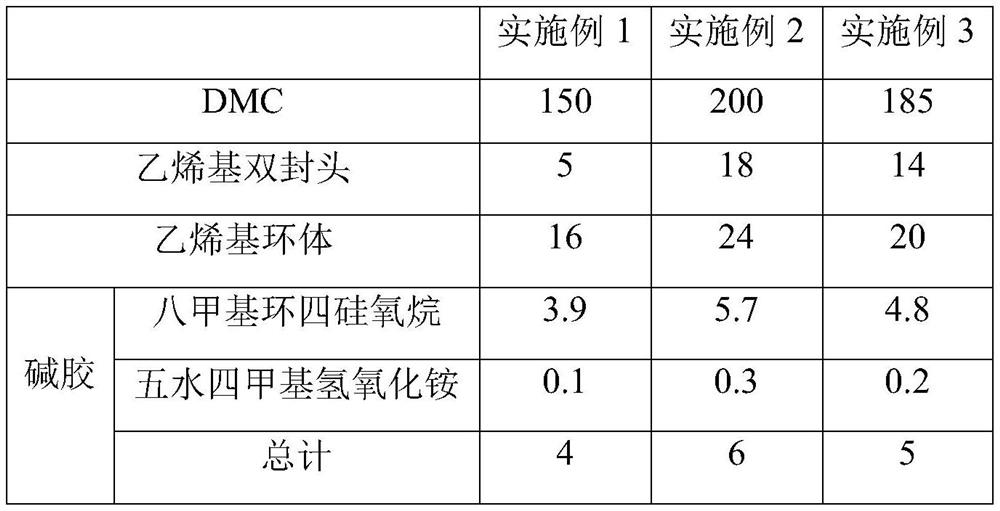

Embodiment 1

[0038] The present embodiment discloses a preparation method of vinyl silicone oil, comprising the following steps:

[0039] (1) Dehydration section: put DMC (see Table 2 for consumption) into the reactor, then heat up to 65°C, turn on the vacuum, keep the vacuum at -0.08Mpa, and dehydrate for 1h;

[0040] (2) Preparation of alkaline glue: add octamethylcyclotetrasiloxane (see Table 2 for the amount) to the flask, cool the system to 0°C, turn on the vacuum, and introduce dry nitrogen for 0.5h; hydrogen tetramethyl pentahydrate Ammonium (see Table 2 for the amount) was added to the flask, continued to open the vacuum, introduced dry nitrogen for 1 h, then reduced the nitrogen ventilation speed and vacuum strength, slowly heated up, and dehydrated to obtain an alkaline glue;

[0041] (3) Equilibrium chemical section: put the alkali glue, vinyl double end caps and vinyl ring body (see Table 2 for the amount) into the reaction kettle, heat up to 95°C, stir and polymerize at a rota...

Embodiment 2

[0046] A preparation method of vinyl silicone oil, comprising the following steps:

[0047] (1) Dehydration section: put DMC (see Table 2 for consumption) into the reaction kettle, then heat up to 70°C, turn on the vacuum, keep the vacuum at -0.15Mpa, and dehydrate for 2h;

[0048] (2) Preparation of alkaline glue: add octamethylcyclotetrasiloxane (see Table 2 for the amount) to the flask, cool the system to 5°C, turn on the vacuum, and feed dry nitrogen for 1 h; tetramethylammonium hydroxide pentahydrate (consumption is shown in Table 2) add in the flask, continue to open the vacuum, feed dry nitrogen for 2h, then reduce the nitrogen ventilation speed and vacuum strength, slowly heat up, and dehydrate to obtain alkali glue;

[0049](3) Equilibrium chemical section: put the alkali glue, vinyl double end caps and vinyl ring bodies (see Table 2 for the amount) into the reaction kettle, heat up to 105°C, and stir and polymerize at a rotational speed of 120r / min for 3h to obtain a...

Embodiment 3

[0054] A preparation method of vinyl silicone oil, comprising the following steps:

[0055] (1) Dehydration section: put DMC (see Table 2 for the amount) into the reaction kettle, then heat up to 68°C, turn on the vacuum, keep the degree of vacuum at -0.10Mpa, and dehydrate for 1.5h;

[0056] (2) Preparation of alkaline glue: add octamethylcyclotetrasiloxane (see Table 2 for the amount) to the flask, cool the system to 4°C, turn on the vacuum, and feed dry nitrogen for 0.5h; tetramethyl pentahydrate is hydrogenated Ammonium (see Table 2 for consumption) was added to the flask, the vacuum was continued to be opened, and dry nitrogen was introduced for 2h, and then the nitrogen ventilation speed and vacuum strength were reduced, the temperature was slowly heated, and dehydrated to obtain alkaline glue;

[0057] (3) Equilibrium chemical section: put the alkali glue, vinyl double end cap and vinyl ring body (see Table 2 for the amount) into the reaction kettle, heat up to 100 ° C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com