Graphitized porous coke coking device

A graphitization and coke technology, applied in the field of coking, can solve problems such as accidents, increased labor consumption, complicated operation methods, etc., and achieve the effect of improving high quality and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with embodiment, the present invention is described in further detail:

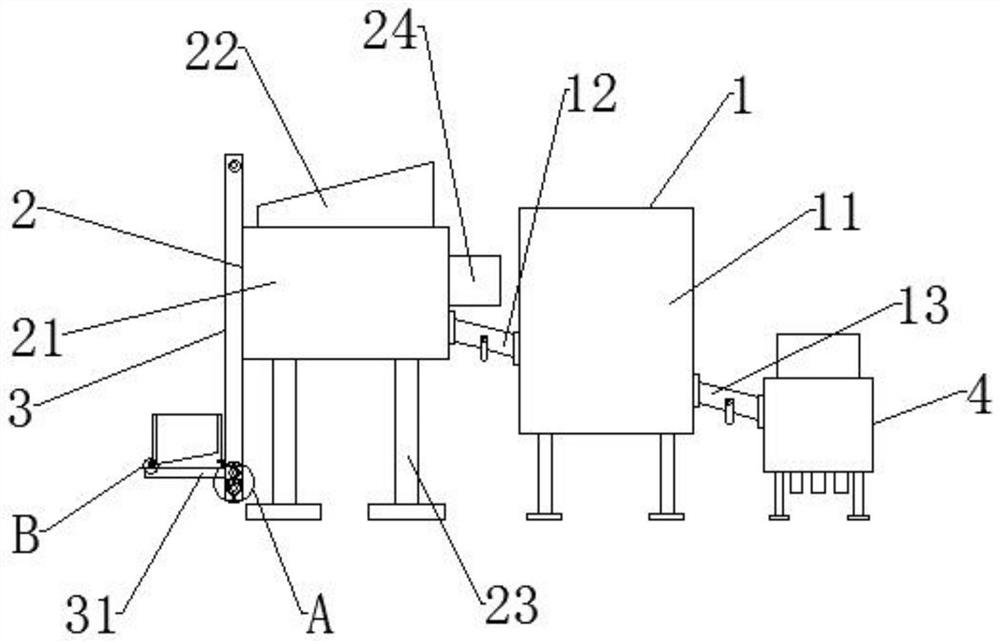

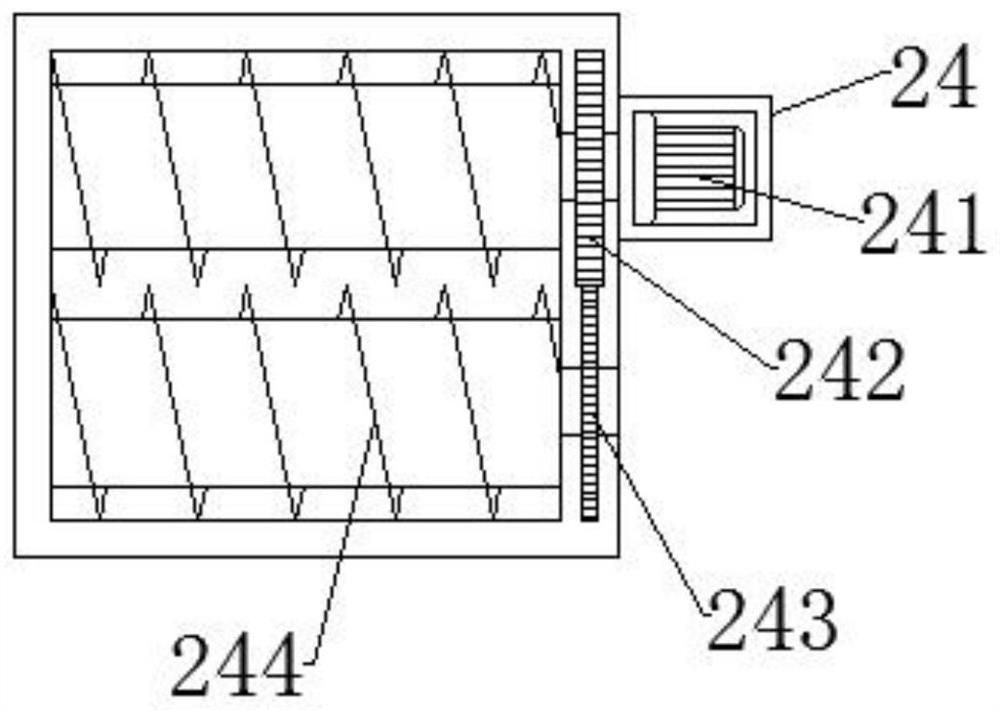

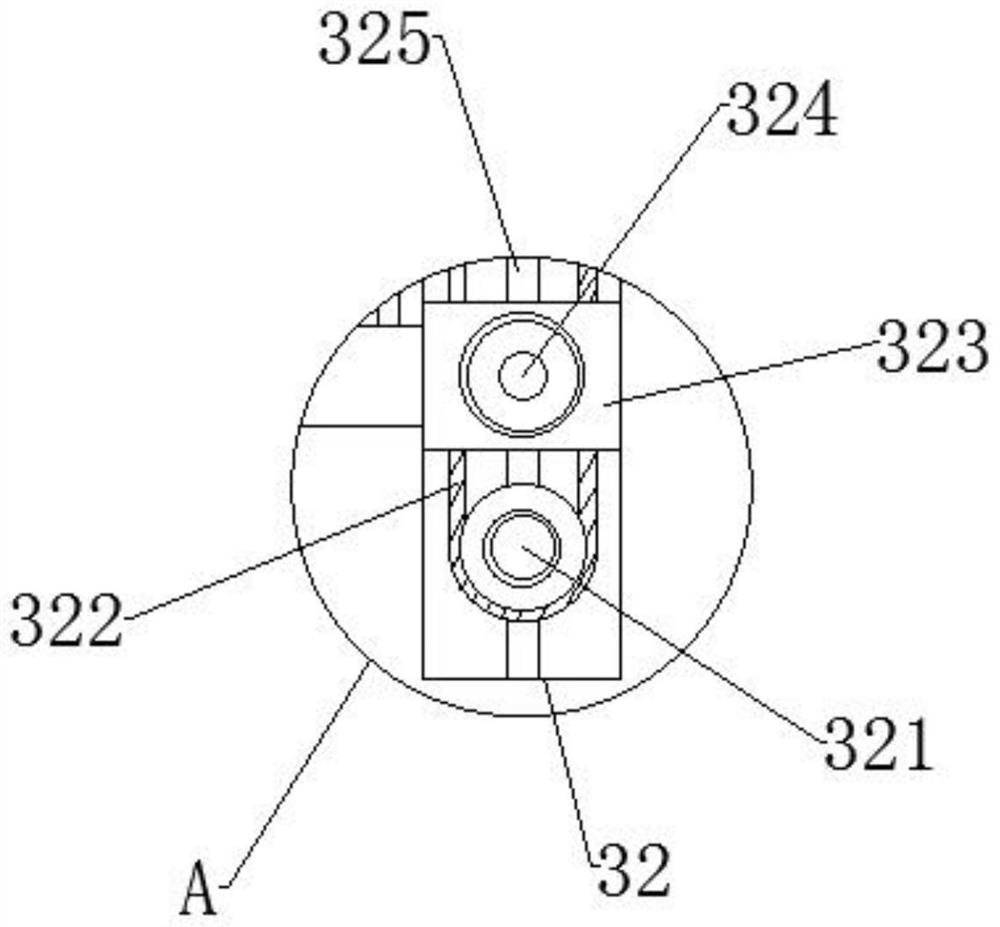

[0034] like Figure 1-6 As shown, it includes the main body 1, the left side of the main body 1 is provided with a feeding mechanism 2, the left side of the feeding mechanism 2 is provided with a feeding mechanism 3, the right side of the main body 1 is provided with a feeding mechanism 4, and the feeding mechanism The mechanism 2 includes a loading box 21, and the inside of the loading box 21 is provided with a crushing device 24, and the feeding mechanism 3 includes a drop box 31, one end of the bottom of the drop box 31 is provided with a lifting device 32, and the other end of the bottom of the drop box 31 is provided There is a fixing device 33 , the material distribution mechanism 4 includes a discharging box 41 , a cooling device 42 is arranged above the discharging box 41 , and a screening device 43 is arranged at the inner bottom of the discharging box 41 .

[0035] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com