Production process of low-odor low-VOC (volatile organic compound) cowhide sofa leather

A production process and low-odor technology, applied in leather impregnation, leather surface treatment, special leather manufacturing, etc., can solve the problems of high VOC content, heavy odor, etc., achieve the effect of reducing residue, easy process control, and ensuring ecological and environmental protection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

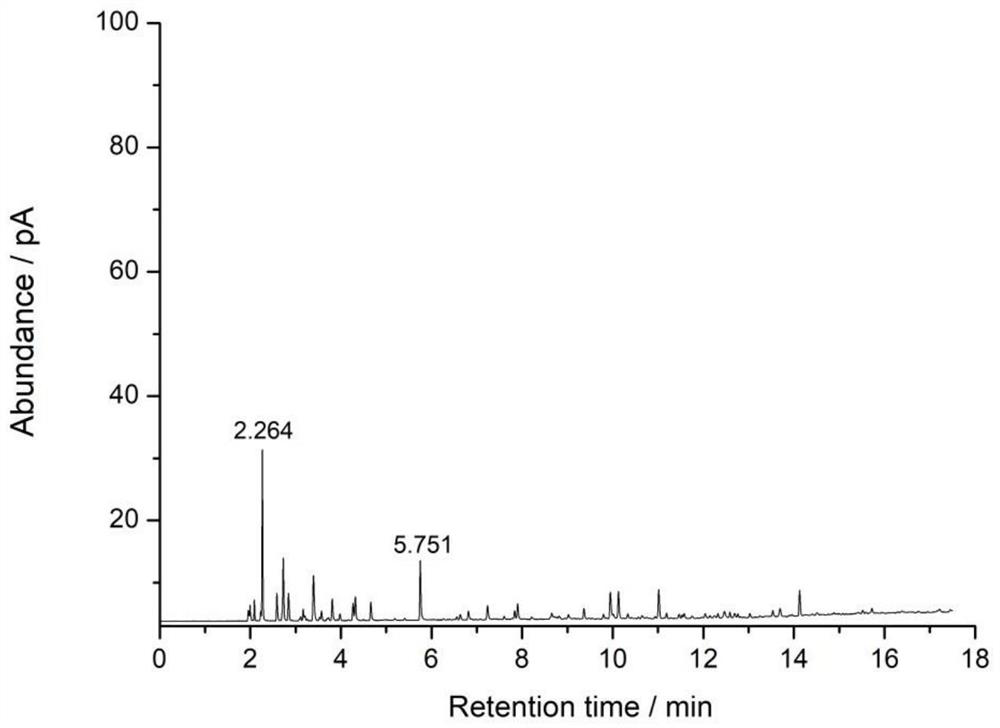

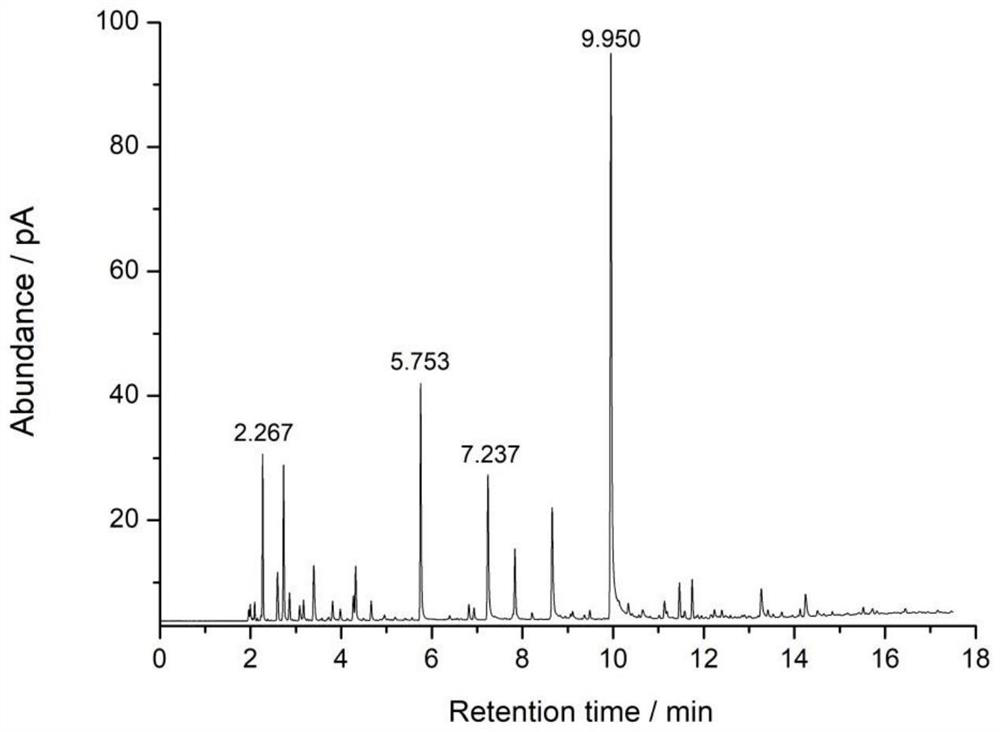

Image

Examples

Embodiment 1

[0030] A production process of low odor and low VOC cowhide sofa leather, the steps of which include:

[0031] a) Water immersion: the raw skin is immersed in water by mixing oil microorganisms and enzymes;

[0032] b) Degreasing: Calculated by taking the raw material skin weight as 100 parts, adding 1 part of lipase DOWELLZYM HK, 800.5 parts of degreasing agent Supralan, at a temperature of 30-35 ° C, rotating for 30 minutes, and then softening;

[0033] c) tanning: use zeolite tanning agent with zeolite as the main ingredient to tan the leather after the degreasing treatment in step b) to obtain wet white leather; carry out in pickling solution, add zeolite tanning agent ZLR-1004 parts, rotate for 4h , add 1.2 parts of baking soda (add in 3 times), pH=4.0-4.2; add 0.5 part of antifungal agent 30L, rotate for 60 minutes;

[0034] d) retanning: adopt sulfone bridge type synthetic tanning agent to carry out retanning, and the sulfone bridge type synthetic tanning agent and the...

Embodiment 2

[0048] The same as Example 1, the difference is that the raw hide has a large difference in position, thick fibers, and a large amount of fat in the raw hide, so it needs to be strengthened in the water immersion and degreasing processes.

[0049] In the soaking process, the first dosage of the soaking agent Proviera was replaced with 2 parts, and the second dosage was replaced with 2 parts.

[0050] In the degreasing step, the amount of degreasing agent Supralan 80 was replaced by 1.0 part, and the rotation time was replaced by 50 minutes.

Embodiment 3

[0052] It is the same as Example 1, except that the amount of degreasing agent Supralan 80 in Example 1 is replaced by 1.0 part, and the rotation time is replaced by 50 minutes.

[0053] During the finishing operation, the primer spray amount was replaced with 30g / m2 2 , the water-based pigment paste used in the middle coating is replaced by 40 parts, and the spraying amount is replaced by 25g / m 2 .

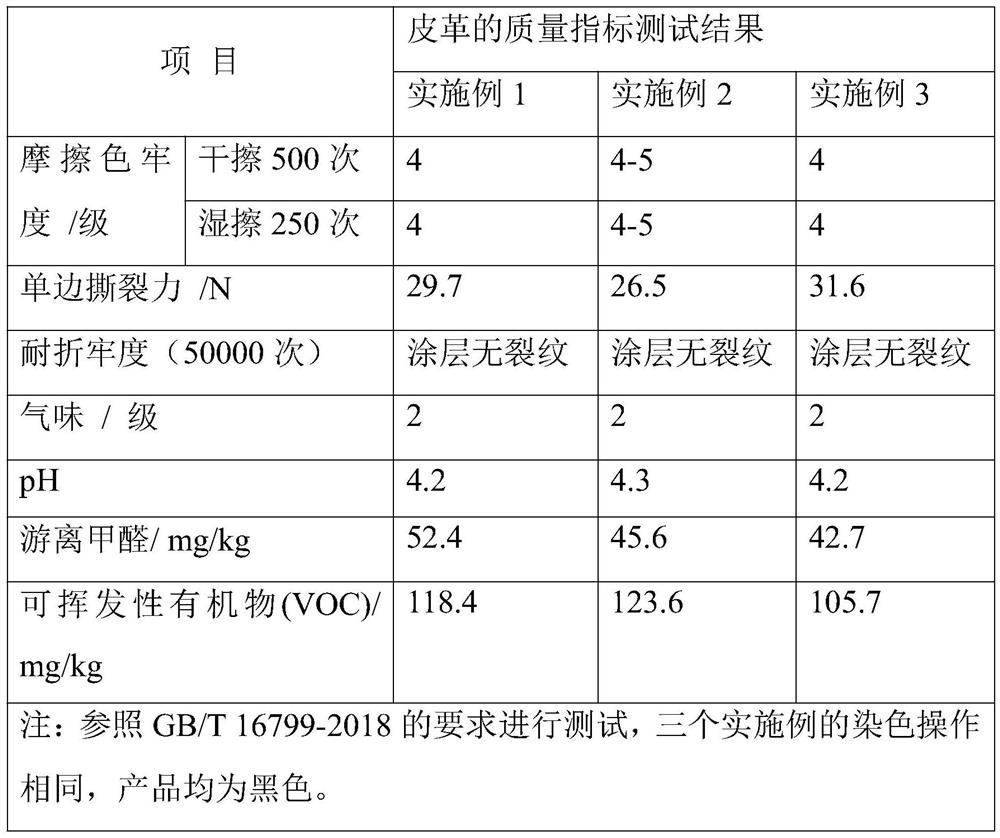

[0054] The main quality index detection result of the leather produced by Example 1, Example 2 and Example 3

[0055] Table 1 The main quality index detection result of leather produced by the process of the present invention

[0056]

[0057] The main quality index test results of the leather produced by the process of the present invention (Example 1, Example 2, and Example 3) are listed in Table 1. Comparing with the content of the current national standard GB / T 16799-2018, it can be seen that the measured indexes all meet the requirements of the current standard, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com