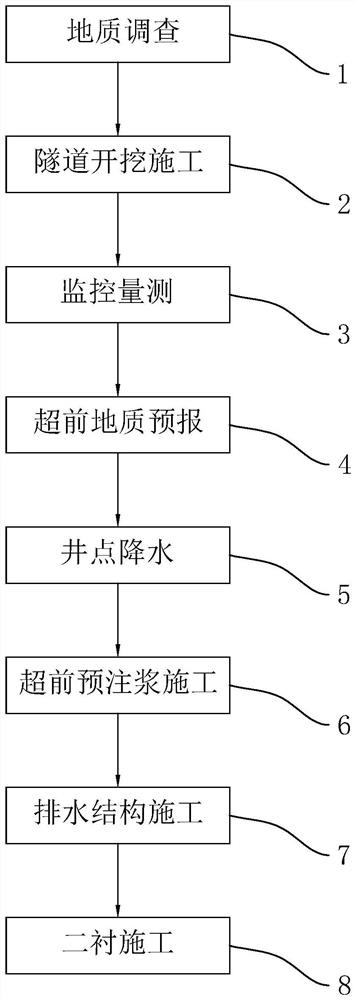

Impermeable drainage construction method for complex soft rock tunnel

A construction method, anti-seepage and drainage technology, applied in tunnels, drainage, tunnel lining, etc., can solve problems such as tunnel water seepage, achieve the effects of ensuring smooth construction, reducing permanent loads, and ensuring smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the technical means realized by the present invention, the features of creation, the achievement of the purpose and the function more clear and easy to understand, the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

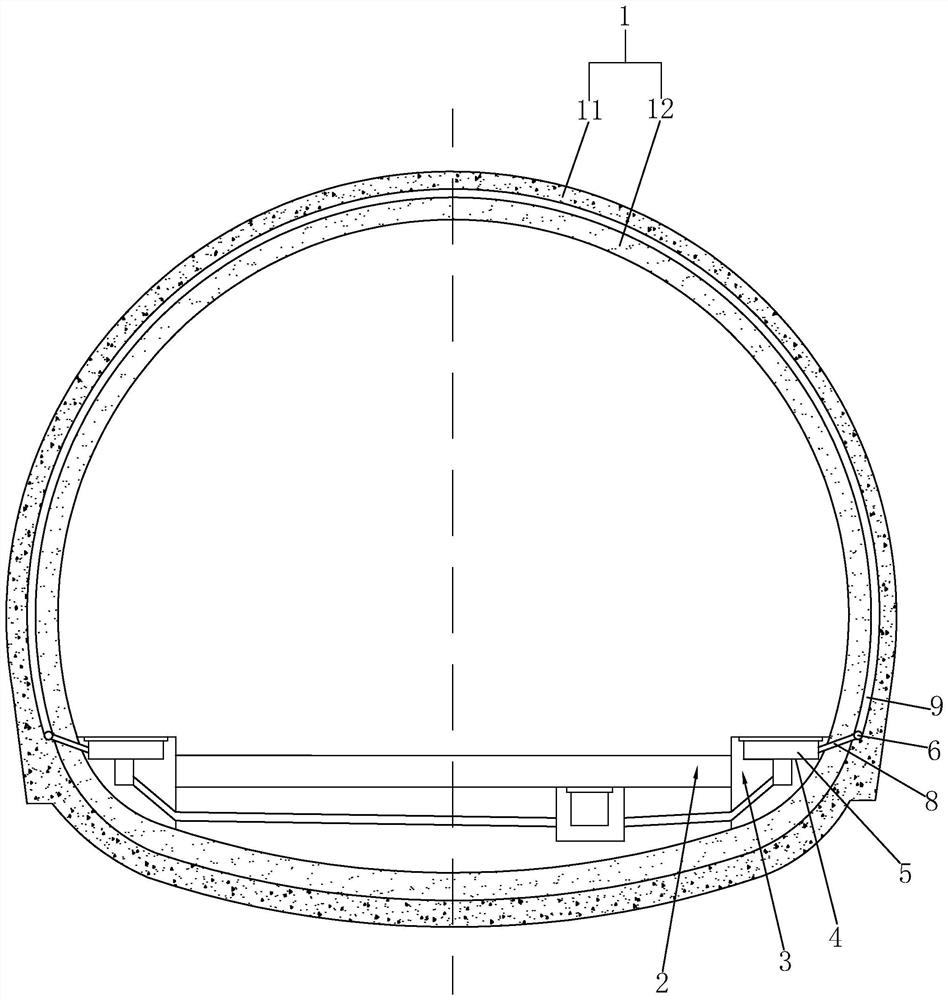

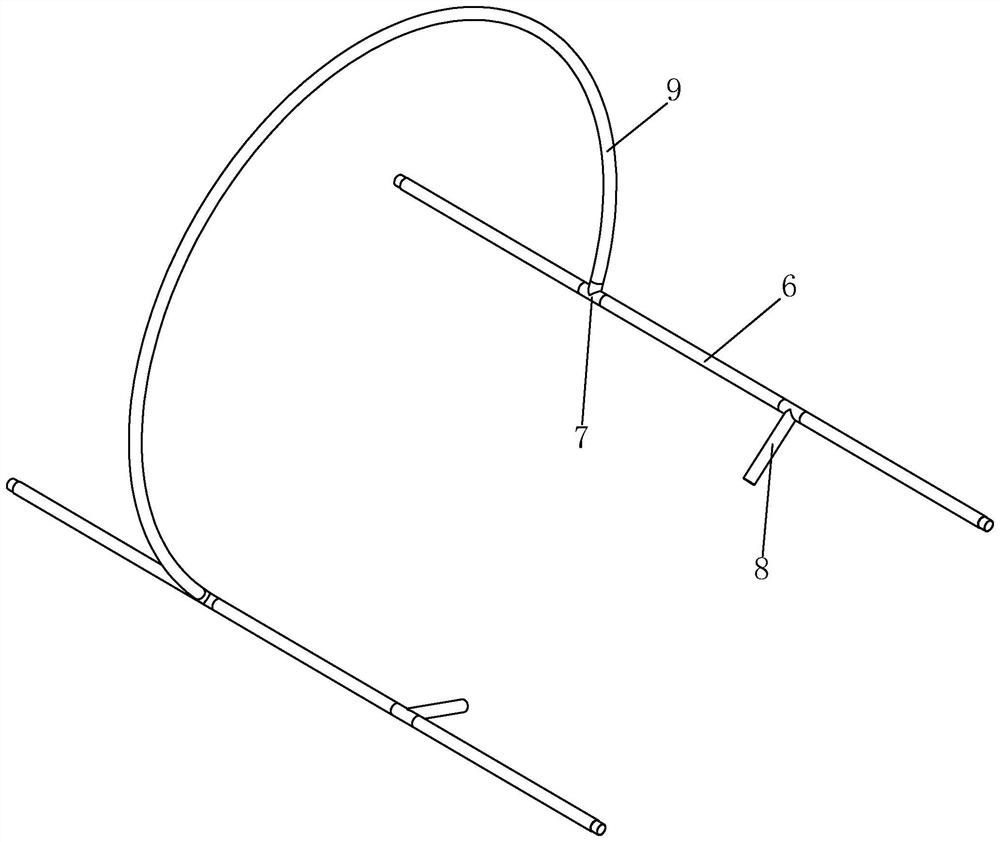

[0063] like figure 1 and 2 As shown, the present invention proposes an anti-seepage and drainage structure for a complex soft rock tunnel, including a tunnel body 1 having a tunnel, a lane 2 for driving in the tunnel, sidewalks 3 located on both sides of the lane 2, and the sidewalk 3 A groove 4 is opened on the road surface of the tunnel, and a drainage ditch 5 is embedded in the groove 4. The drainage ditch 5 is a prefabricated resin-integrated drainage ditch 5, and the drainage ditch 5 is sequentially spliced along the longitudinal direction of the tunnel body 1.

[0064] like figure 1 and 2 As shown, the tunnel body 1 includes a primary lining 11 and a seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com