Method for detecting keratin by using ThioGlo1 fluorescent probe

A fluorescent probe and keratin technology, applied in the field of keratin detection, can solve the problems of difficult extraction of keratin and difficulty in dissolving natural keratin, and achieve the effect of sensitive detection and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

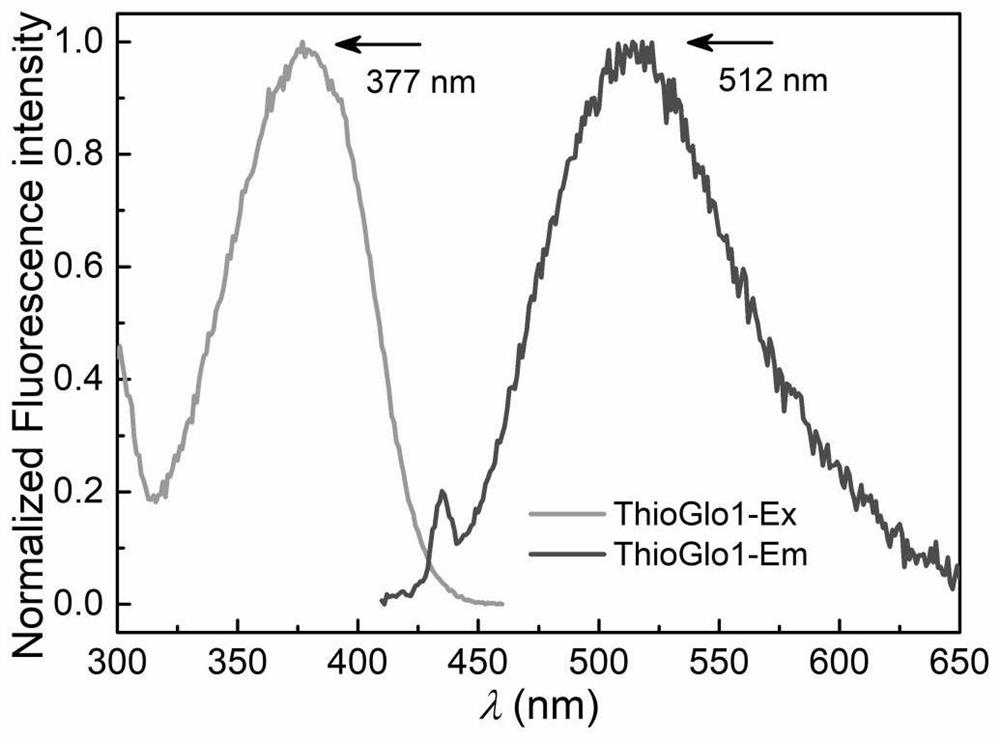

[0029] 1. At room temperature, accurately weigh 1-5mg ThioGlo1 sample and prepare it into 1×10 with DMSO -5 mol / L solution for later use.

[0030] 2. Use phosphate buffer solution with pH 7.4 to prepare waste wool keratin into solutions of different concentrations (1-100×10 -5 mol / L).

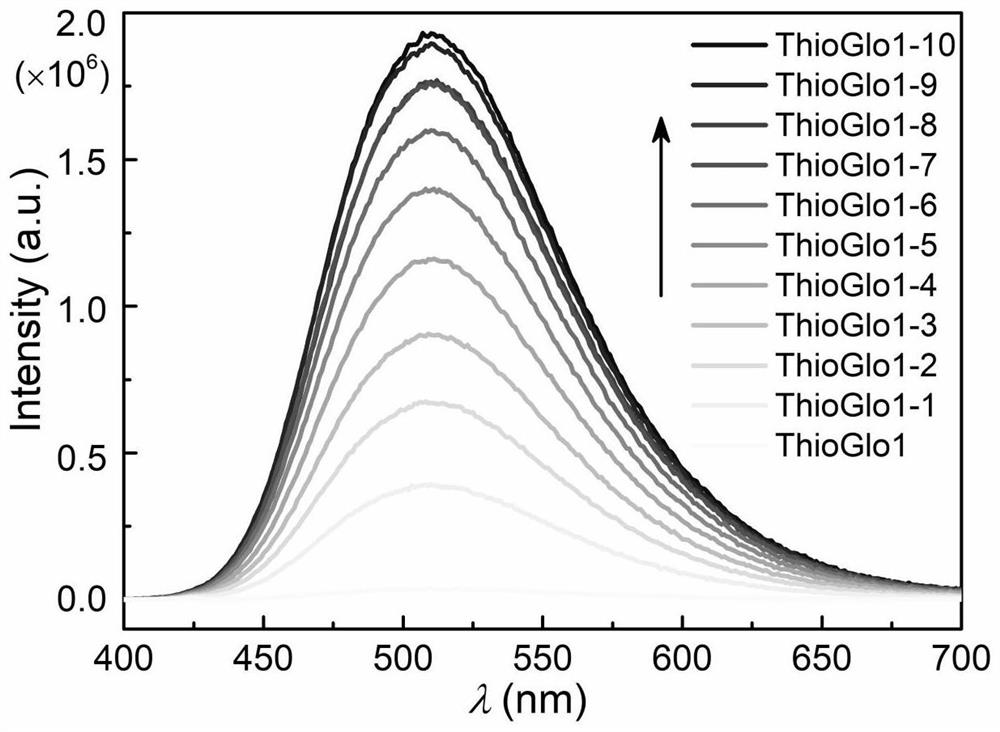

[0031] 3. Add 20μL of dissolved 1×10 to the 3.0mL colorimetric tube. -5 mol / L ThioGlo1 solution, 2.5mL phosphate buffer solution, different concentrations (5, 10, 20, 30, 40, 50, 60, 80, 90 and 100×10 -5 mol / L) waste keratin solution 20 μL, image 3 ThioGlo1 in represents the control without added waste keratin. Dilute the phosphate buffer solution to 3.0 mL, shake well, and react at room temperature for 15 min.

[0032] 4. Use a FluoroLog-3 steady-state transient fluorescence spectrometer to detect the emission wavelength λ em = Fluorescence intensity around 510 nm, excitation wavelength λ ex =340nm.

[0033] The result is as image 3 As shown, in the figure, ThioGlo1-1 to ThioGlo1-10...

Embodiment 2

[0036] 1. At room temperature, accurately weigh 1-5mg ThioGlo1 sample and prepare it into 1×10 with DMSO -5 mol / L solution for later use.

[0037] 2. Use a phosphate buffer solution with a pH of 7.4 to prepare waste chicken feather keratin into solutions of different concentrations (1-100×10 -5 ).

[0038] 3. Add 20 μL of dissolved ThioGlo1 solution, 2.5 mL of phosphate buffer solution, and different concentrations (concentrations of 10, 20, 30, 50, 60, 80, 90 and 100 × 10) into a 3.0 mL colorimetric tube. 5 mol / L) 20 μL of discarded keratin solution. Dilute the phosphate buffer solution to 3.0 mL, shake well, and react at room temperature for 15 min.

[0039] 3. Use a FluoroLog-3 steady-state transient fluorescence spectrometer to detect the emission wavelength λ em = Fluorescence intensity around 510 nm, excitation wavelength λ ex =340nm.

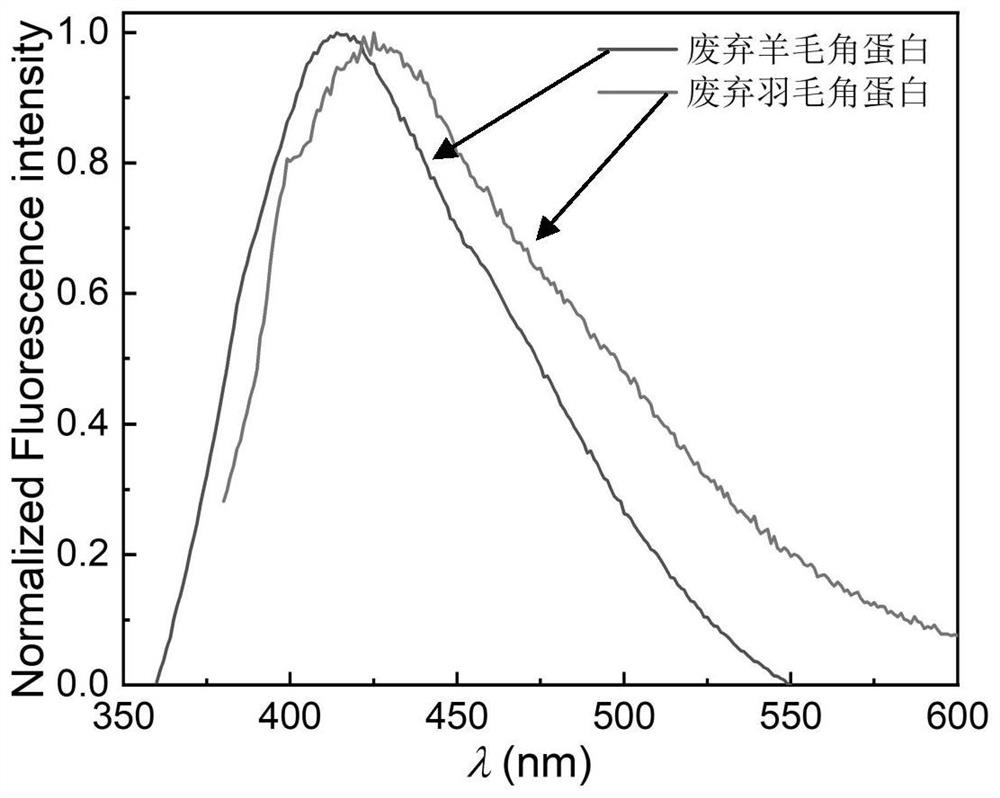

[0040] The result is as Figure 4 As shown in the figure, ThioGlo1-12 to ThioGlo1-19 in the figure are the fluorescence emission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com