Olefin polymer films and methods of making same

A technology of olefin polymers and compounds, applied in the field of olefin polymer film and its preparation, can solve the problems of poor heat sealability, poor processability, narrow molecular weight distribution, etc., and achieve the effects of easy film forming, excellent mechanical strength and heat sealability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

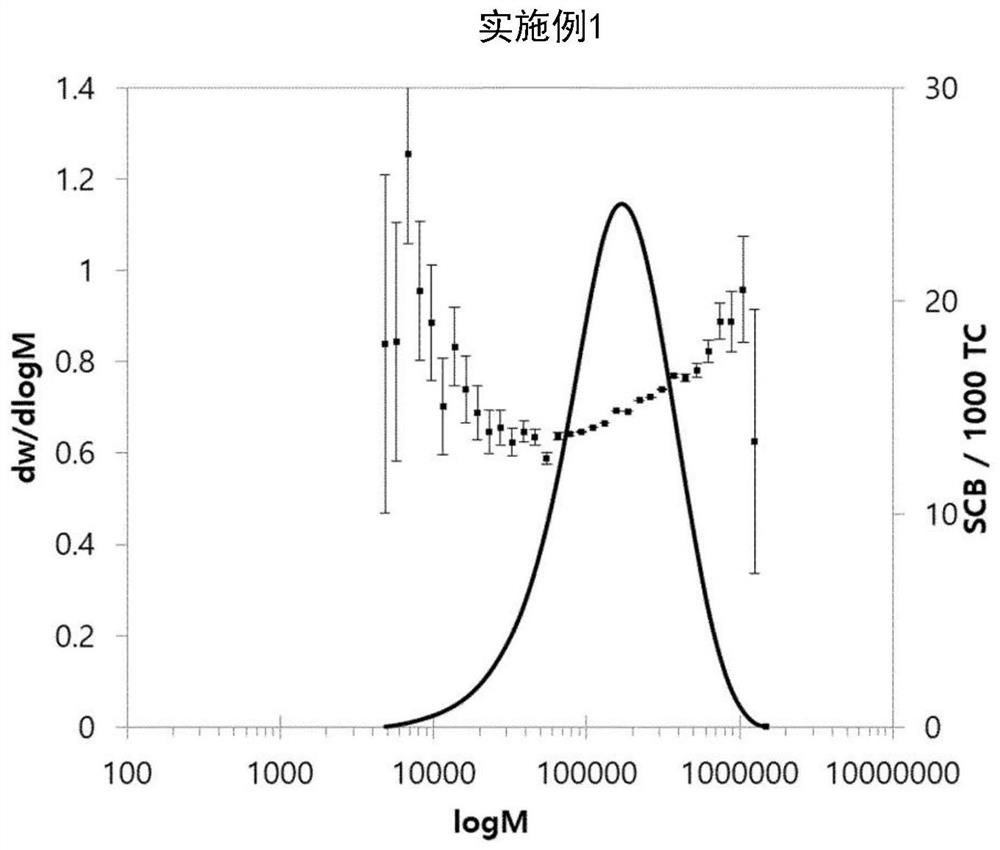

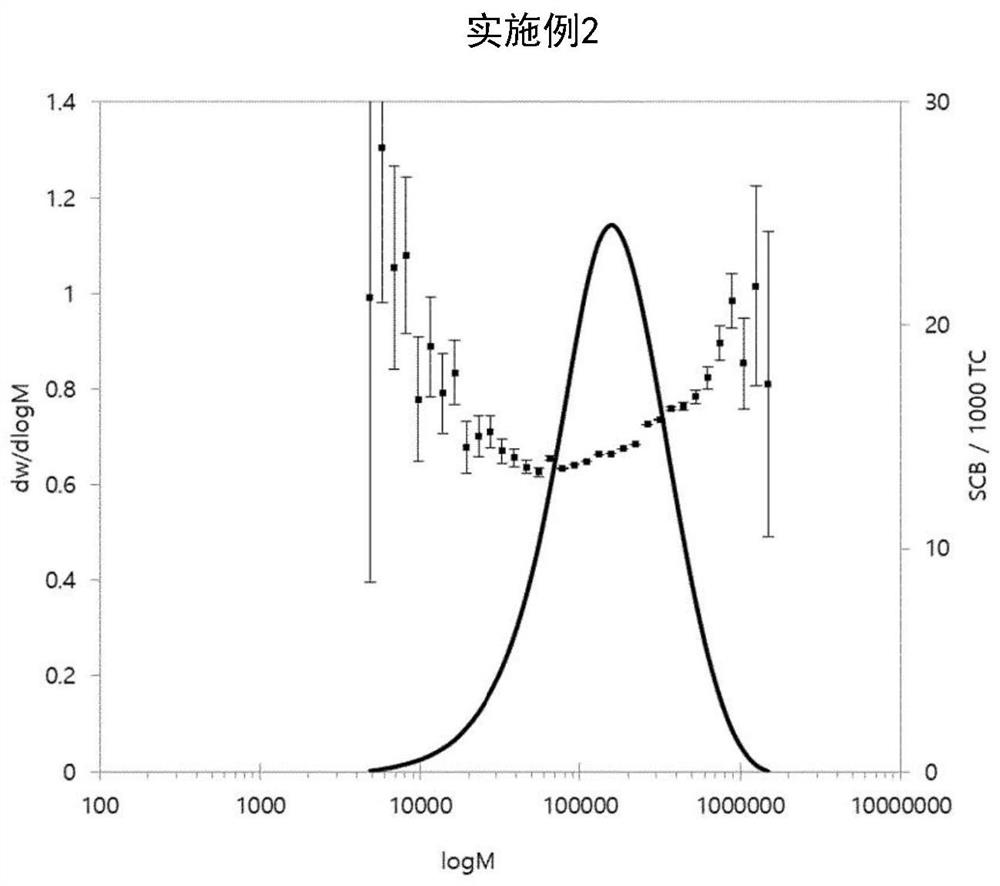

Examples

preparation example Construction

[0126] Preparation method of olefin polymer film

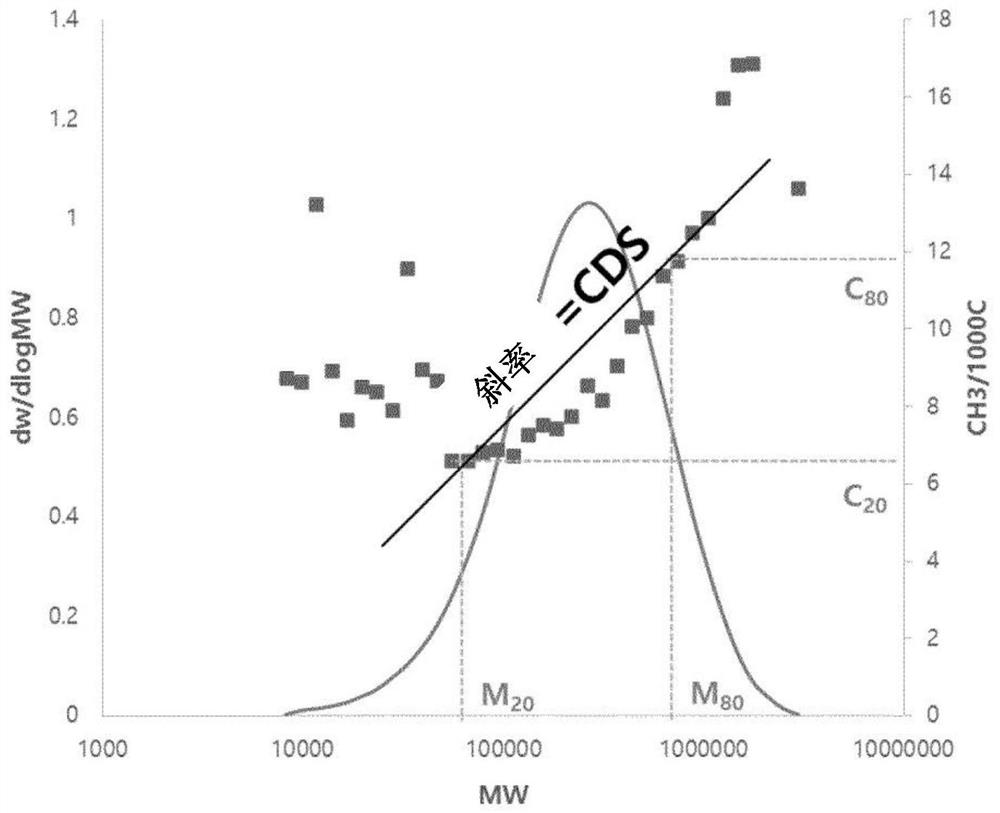

[0127] In a specific embodiment, the present invention provides a method for preparing an olefin polymer film, the method comprising: step (a), in a process comprising at least one transition metal compound represented by the following Chemical Formula 1 and at least one co-catalyst In the presence of the catalyst of the compound, the olefin monomer is polymerized to obtain an olefin polymer; and in step (b), the olefin polymer is formed to obtain a film, wherein the olefin polymer satisfies: (1) a density of 0.910 g / cm 3 to 0.940g / cm 3 , preferably 0.910g / cm 3 to 0.920g / cm 3 ; (2) Melt index (I 21.6 ) and the melt index (I 2.16 ) ratio (MFR) of 10 to 60, preferably 20 to 40; and (3) a comonomer distribution slope (CDS) defined by the following Mathematical formula 1 of 1 or more, preferably 2 to 5, the olefin polymer The film has a heat seal strength of 90 gf / 2.5cm or more, preferably 90 to 200 gf / 2.5cm, measured at 0....

preparation Embodiment 1

[0139][Preparation Example 1] bis[(2-trimethylsilylmethylallyl)cyclopentadienyl]hafnium dichloride (bis[(2-trimethylsilylmethylallyl)cyclopentadienyl]hafnium dichloride; chemical formula 1- 9) Preparation

[0140] 2-(trimethylsilylmethyl)-2-propen-1-ol (2-(trimethylsilylmethyl)-2-propen- 1-ol) preparation

[0141] To a solution prepared by dissolving 2-(trimethylsilylmethyl)allylacetate (2-(trimethylsilylmethyl)allylacetate; 2.69 g, 14.4 mmol) in methanol (22 mL), potassium carbonate ( K 2 CO 3 ) in water (6.6 M, 14.4 mmol). After the addition was complete, it was stirred at room temperature for 4 hours. After stirring, water was added thereto to terminate the reaction. After the organic layer was extracted with diethyl ether, the organic layer was extracted with magnesium sulfate (MgSO 4 ) to remove residual water. All solvents were removed under vacuum to obtain 1.51 g (72%) of a pale yellow oil compound.

[0142] 1 H-NMR (CDCl 3 , 300MHz): δ4.90-4.88(m, 1H), 4...

preparation Embodiment 2

[0159] [Preparation Example 2] dimethyl bis[(2-trimethylsilylmethylallyl)cyclopentadienyl]hafnium (dimethyl bis[(2-trimethyl silylmethylallyl)cyclopentadienyl]hafnium; chemical formula 1- 10) Preparation

[0160] To the mixture obtained by diluting bis[2-(trimethylsilylmethyl)allyl]cyclopentadienyl hafnium dichloride (2.4 g, 3.79 mmole) prepared in Preparation Example 1 in toluene To the solution, MeMgBr (3.0 M in diethyl ether, 11.4 mmole) was slowly added at -30°C, then the temperature was slowly raised to room temperature and stirred for 12 hours. When the reaction was complete, extraction was performed with toluene and filtration, and the solvent of the filtrate was dried under vacuum. The resulting solid was washed with hexane and dried to obtain 2.08 g (93%) of a white solid compound.

[0161] Using 3.87 g of the compound represented by Chemical Formula 1-10, 200 g of a supported catalyst was prepared in the same manner as in Preparation Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com