An anti-oxidation silver-plated nylon fiber with protective film

A nylon fiber, anti-oxidation technology, applied in the field of fiber manufacturing, can solve the problems of short service life, poor protection effect, reaction between human sweat and oxidative substances in the air, etc., and achieve the effect of preventing sweat and air erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

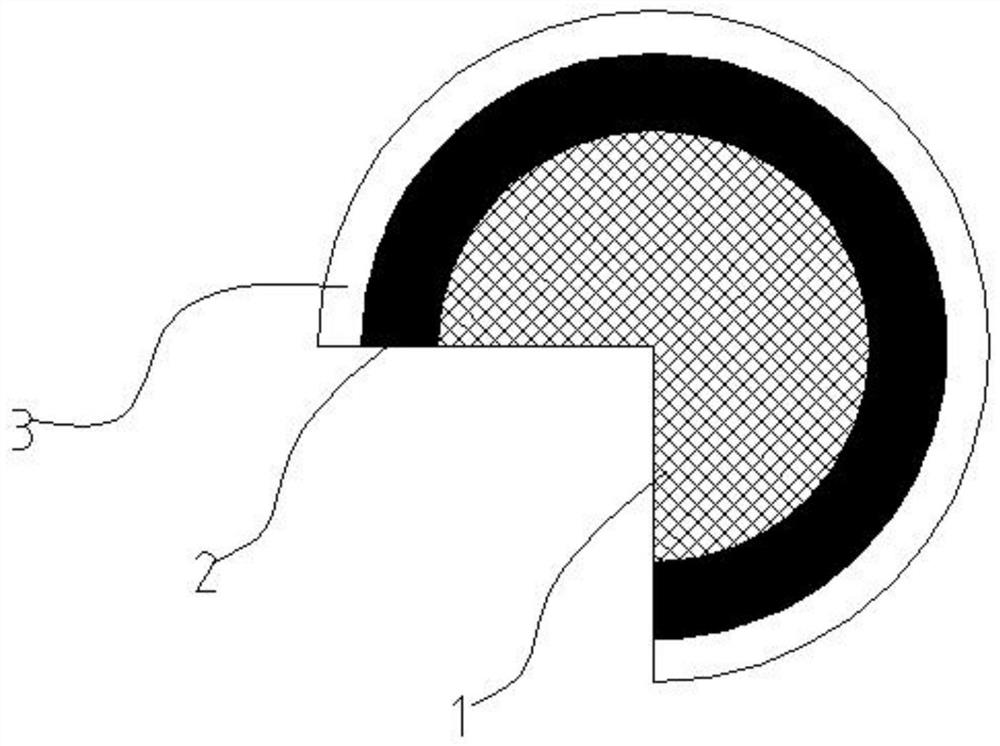

Image

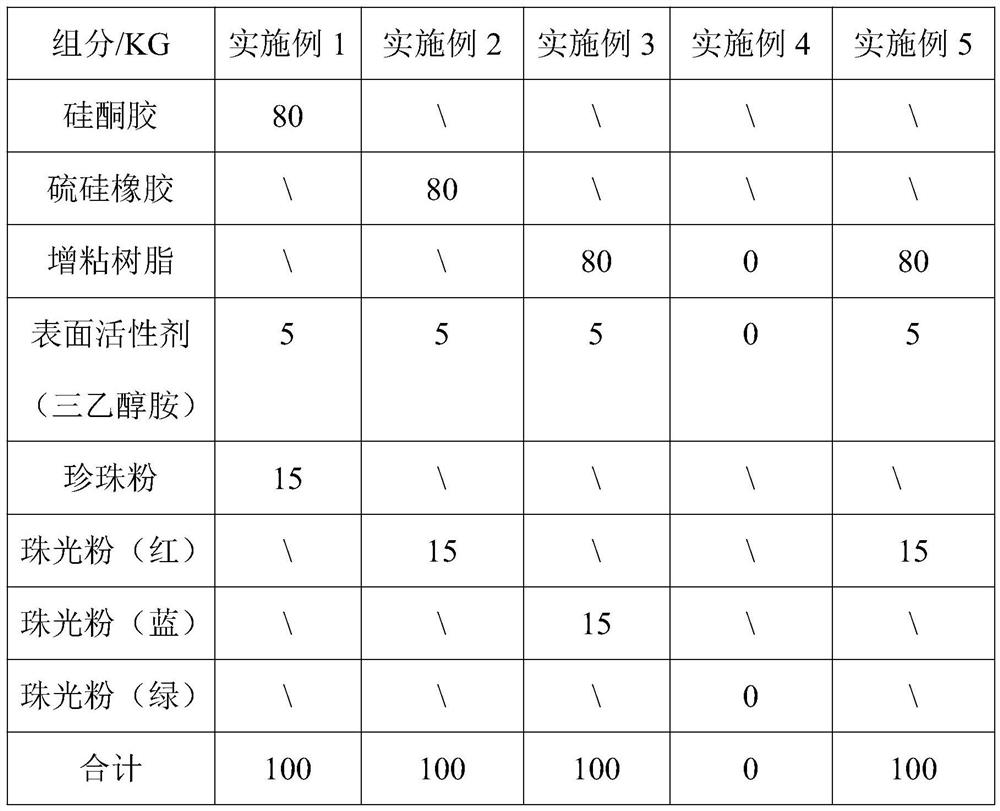

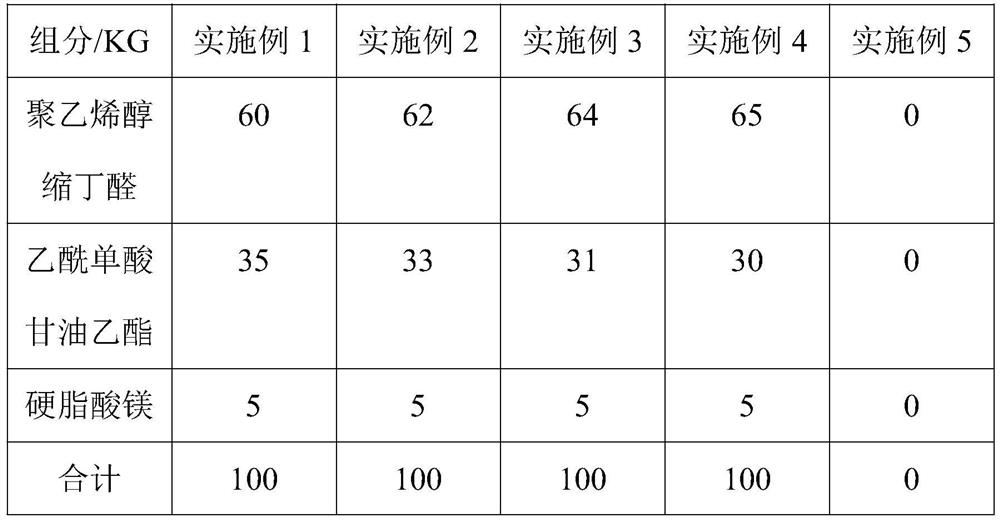

Examples

Embodiment 6

[0036] In embodiment 6, the manufacture method of described oxidation-resistant silver-plated nylon fiber:

[0037]In a vacuum environment at 10 degrees Celsius, the nylon fiber with a diameter of 0.16 cm is soaked in sodium hydroxide solution for pretreatment. After washing with water and drying with hot air, the nylon fiber is placed in the silver ammonia solution for 45 minutes. Ultrasonic equipment with a frequency between 40 Hz and a power of 350 watts assists in coating. After a chemical reaction, the silver precipitate is adsorbed on the surface of the nylon fiber, and then taken out and dried to obtain a silver-plated nylon fiber;

Embodiment 4

[0038] Embodiment 4 is that silver-plated nylon fibers are coated with a protective layer material, without adhesive layer adhesion;

Embodiment 5

[0039] Embodiment 5 is coated with adhesive layer material outside the silver-plated nylon fiber, without protective layer film;

[0040] Embodiment 6 is pure silver-plated nylon fiber, and the outer layer does not cover other materials;

[0041] A. Test method: antibacterial cleaning ability test,

[0042] The test includes placing each example product of the anti-oxidation silver-plated nylon fiber with a protective film that filters the bacteria liquid into 100mL of sterile water, seals and soaks it, and after rinsing for 24 hours, this is called washing liquid, and the antibacterial ability is then It is to calculate the difference in the number of bacteria between the original bacterial liquid and the washing liquid, and the percentage of the number of residual bacteria in the original bacterial liquid,

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com