Strip for circuits having rose gold contact pad and method for manufacturing the strip

A technology of electrical contact pads and strips, which is applied to record carriers, instruments, and calculations used by machines, and can solve problems such as doubtful quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A disclosed example of a circuit made from a strip according to the invention is described below. This example is taken from the field of smart cards, but those skilled in the art will be able to transfer this example to other circuit applications without involving inventive step. In particular, the present invention is particularly beneficial where the use of all pink conductive contacts or pink conductive traces may bring an aesthetic added value (for example to a connector for an SD memory card or a connector for a USB memory stick).

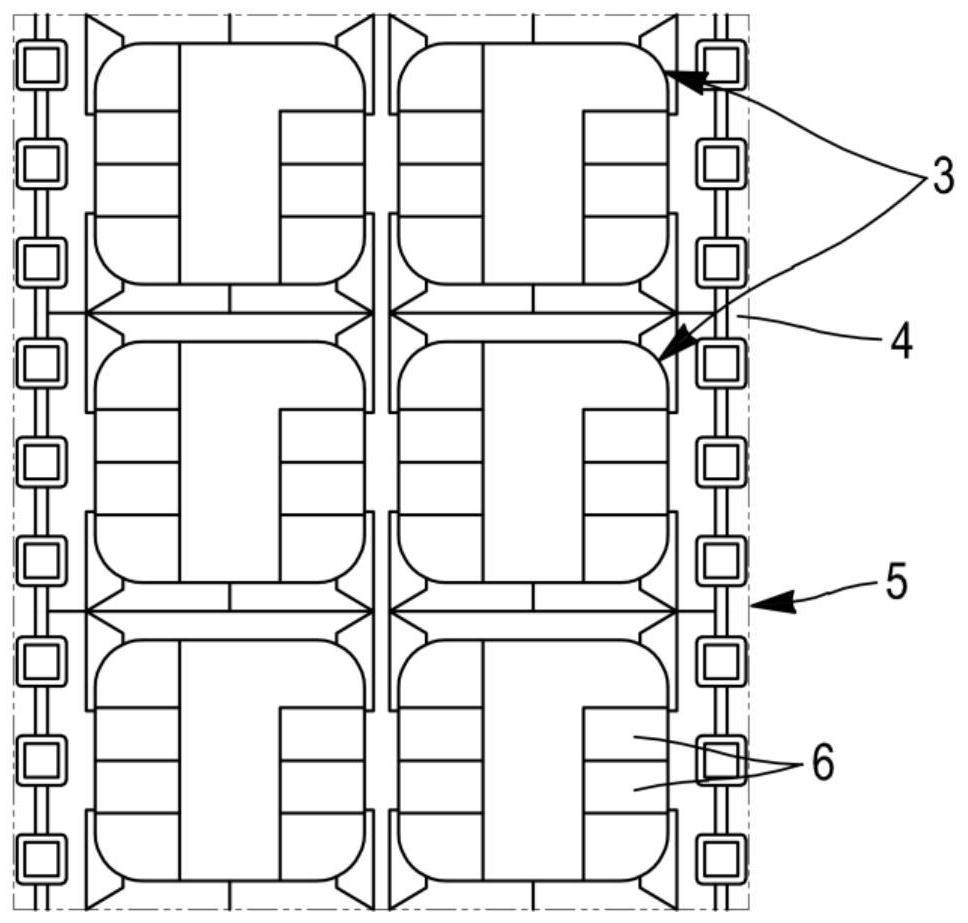

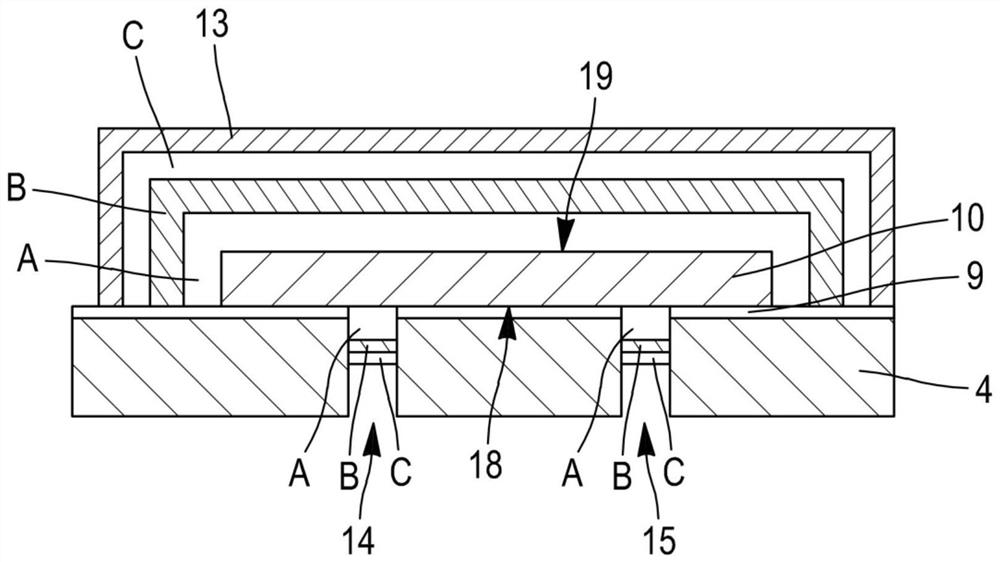

[0014] like figure 1 As shown, the smart card 1 comprises, for example, a module 2 with a connector 3 . The modules 2 are usually made in the form of individual elements cut from strips. This element is inserted into a cavity formed in the card 1 . The element comprises a substantially flexible substrate 4 made of polyethylene terephthalate (PET), glass-epoxy, etc. (see figure 2 ), a connector 3 is formed on the substrate 4, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap