Methylsiloxane cracking tail gas purification treatment system and treatment method

A methylsiloxane and tail gas purification technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of vacuum pump operation influence, gas VOC exceeding the standard, etc., and achieve improved operation stability, extended life, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

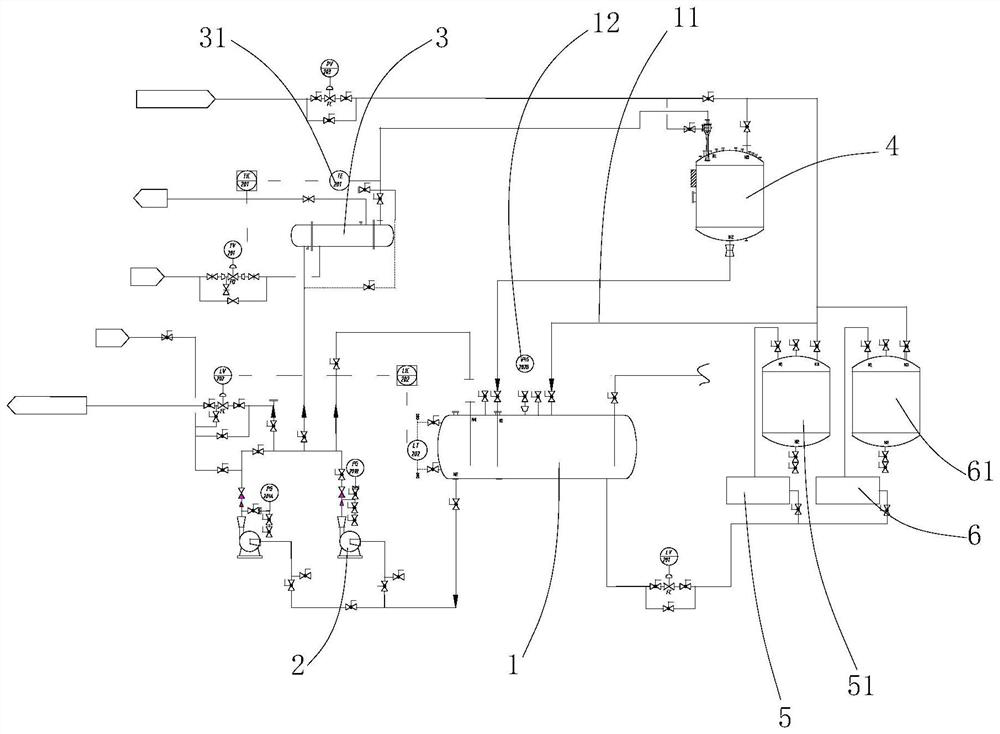

[0028] like figure 1 As shown, this embodiment provides a methylsiloxane pyrolysis tail gas purification treatment system, including an absorption liquid buffer tank 1, an absorption liquid circulation pump 2, an absorption liquid condenser 3, a gas-liquid separator 4 and a first vacuum pump 5 , the absorption liquid buffer tank 1, the absorption liquid circulating pump 2, the absorption liquid condenser 3 and the gas-liquid separator 4 are connected in turn to form a closed loop, the absorption liquid buffer tank 1 and the first vacuum pump 5 form a circulation loop, and the first vacuum pump 5 and the absorption liquid A first vacuum pump buffer tank 51 is arranged between the liquid buffer tank 1, a balance pipe 11 is arranged between the absorption liquid buffer tank 1 and the first vacuum pump 5, and also includes a second vacuum pump 6, the second vacuum pump 6 and the first vacuum pump 5 In parallel, a second vacuum pump buffer tank 61 is arranged between the second vac...

Embodiment 2

[0030] This embodiment provides a method for purifying and treating methylsiloxane cracking tail gas, that is, a method for using the methylsiloxane cracking tail gas purification and treatment system provided in Example 1, as follows:

[0031] In the process of use, it is necessary to inject the absorption liquid (D in the absorption liquid) into the absorption liquid buffer tank in advance. 5 When the liquid level of the absorption liquid buffer tank reaches 60%, start the absorption liquid circulation pump to circulate the system, and the absorption liquid flows through the absorption liquid condenser and gas-liquid separator, and finally returns to the absorption liquid liquid buffer tank. After normal circulation, the pressure of the absorption liquid buffer tank is pumped to a negative pressure of more than 70kPa through the balance pipe at the top of the absorption liquid buffer tank. After the pressure reaches the condition, the vacuum line of the methylsiloxane cracki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com