Sodium-ion battery positive electrode material precursor and preparation method thereof

A technology for sodium ion batteries and cathode materials, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems of poor reversibility of material structure phase transition, slow sodium ion diffusion, and reduced deintercalation speed. Effect of rate capability, improved reversibility, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

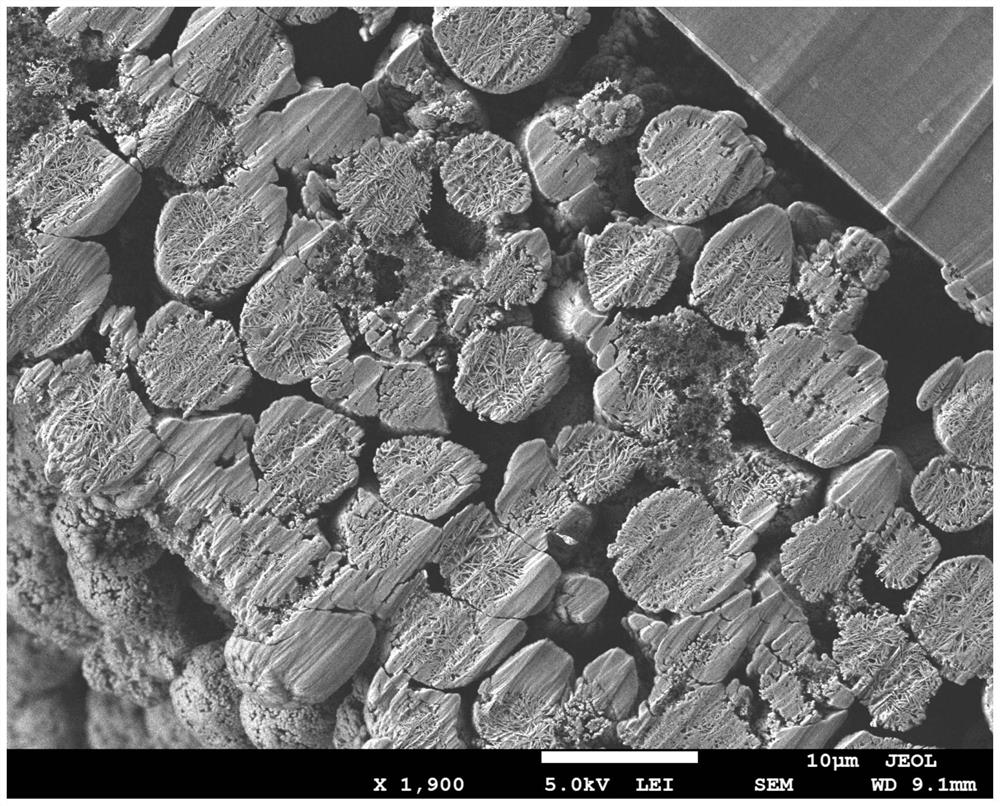

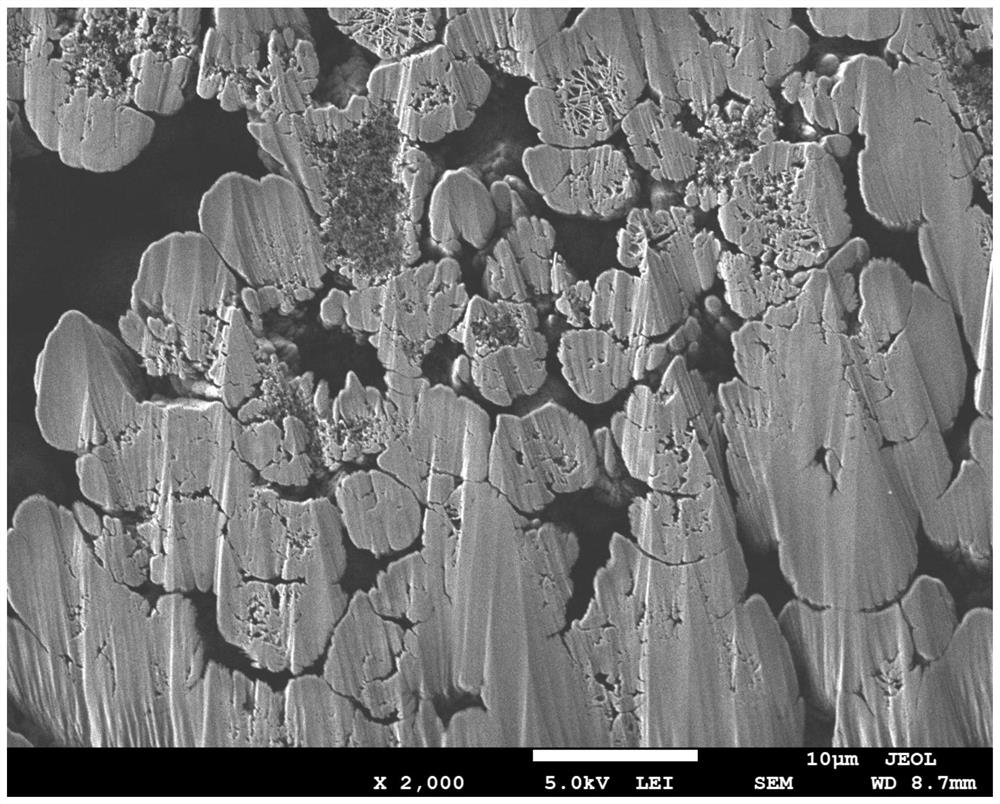

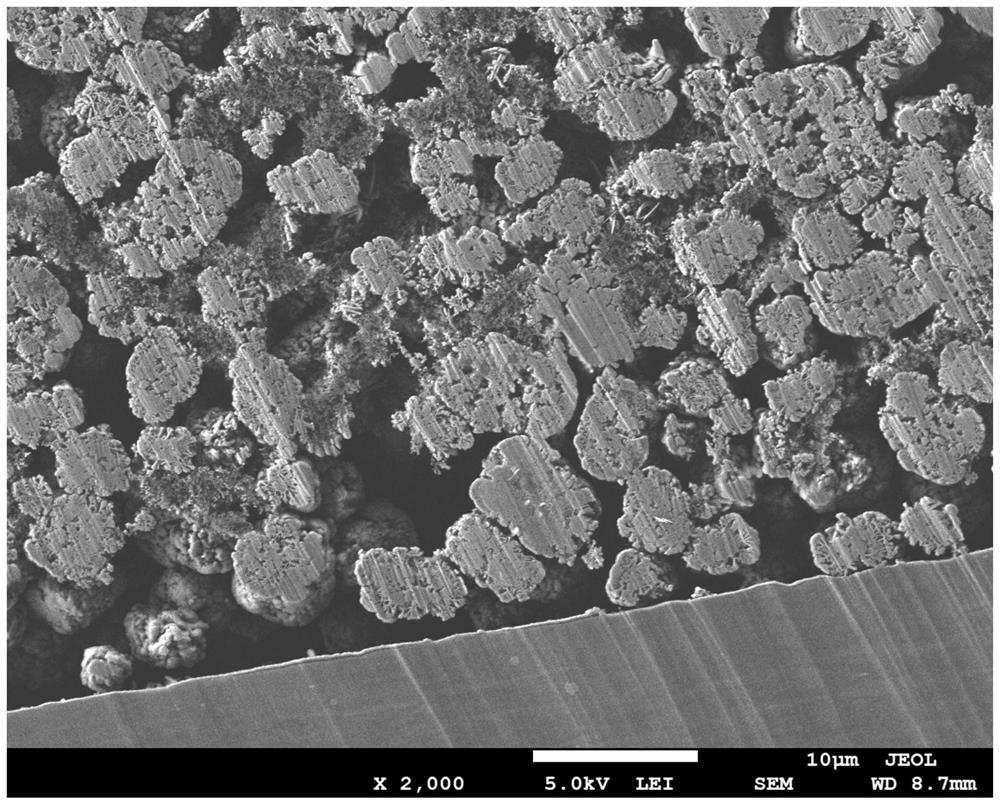

[0035] A method for preparing a cathode material precursor for a sodium ion battery, comprising:

[0036] Step 1: Prepare a mixed solution of Ni, Mn, and Cu salts, wherein the total molar concentration of Ni, Mn, and Cu in the mixed solution is 1.9 mol / L, and the molar ratio is 45:30:25;

[0037] The preparation molar concentration is 10mol / L sodium hydroxide or potassium hydroxide solution as precipitant;

[0038] Aqueous ammonia solution with a molar concentration of 2.5 mol / L was prepared as a complexing agent;

[0039] Step 2, adding pure water, the precipitating agent and the complexing agent to the closed reaction kettle to form a bottom liquid, the pH value of the bottom liquid is controlled by the precipitating agent to be 11.35-11.55, and the pH value of the bottom liquid is controlled by the complexing agent. The ammonia concentration is 0.08mol / L, and the temperature is maintained at 60℃;

[0040] Step 3, keep the stirring of the reactor open, feed the mixed gas o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com