Lotus seed Maillard reactant, preparation method thereof and cigarette feed liquid

A Maillard reactant and Maillard reaction technology are applied in the preparation of tobacco, tobacco, application, etc., and can solve the problems of unsatisfactory extraction effect of active ingredients, waste of raw materials, production cost, and monotonous product aroma, and improve the comfort of cigarettes. The effect of reducing the smoke, reducing the fumes, and modifying the smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention provides a preparation method of lotus seed Maillard reactant for cigarettes, which comprises the following steps:

[0037] 1), carry out cleaning, drying and pulverizing successively by removing the core lotus seeds, obtain lotus seed powder;

[0038] 2), adopt ultrasonic-assisted extraction method, extract the water-soluble polysaccharide in described lotus seed powder, obtain lotus seed extract;

[0039] 3) using compound enzyme to carry out enzymolysis to the lotus seed extract;

[0040] 4), after enzymolysis, carry out successively de-enzyme, sterilization, primary filtration, concentration, secondary filtration, obtain lotus seed extract;

[0041] 5), add amino acid to described lotus seed extract, carry out Maillard reaction, obtain lotus seed Maillard reactant after reaction.

[0042]The above-mentioned step 1) is the process of carrying out lotus seed pretreatment. Since the lotus seed core contains a lot of bitter sub...

Embodiment 1

[0068] 【Preparation of lotus seed Maillard reactant】

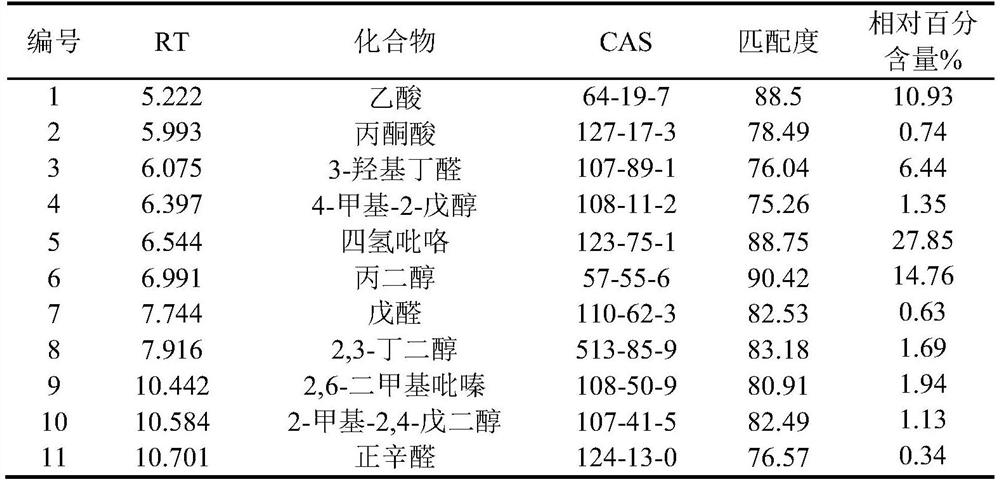

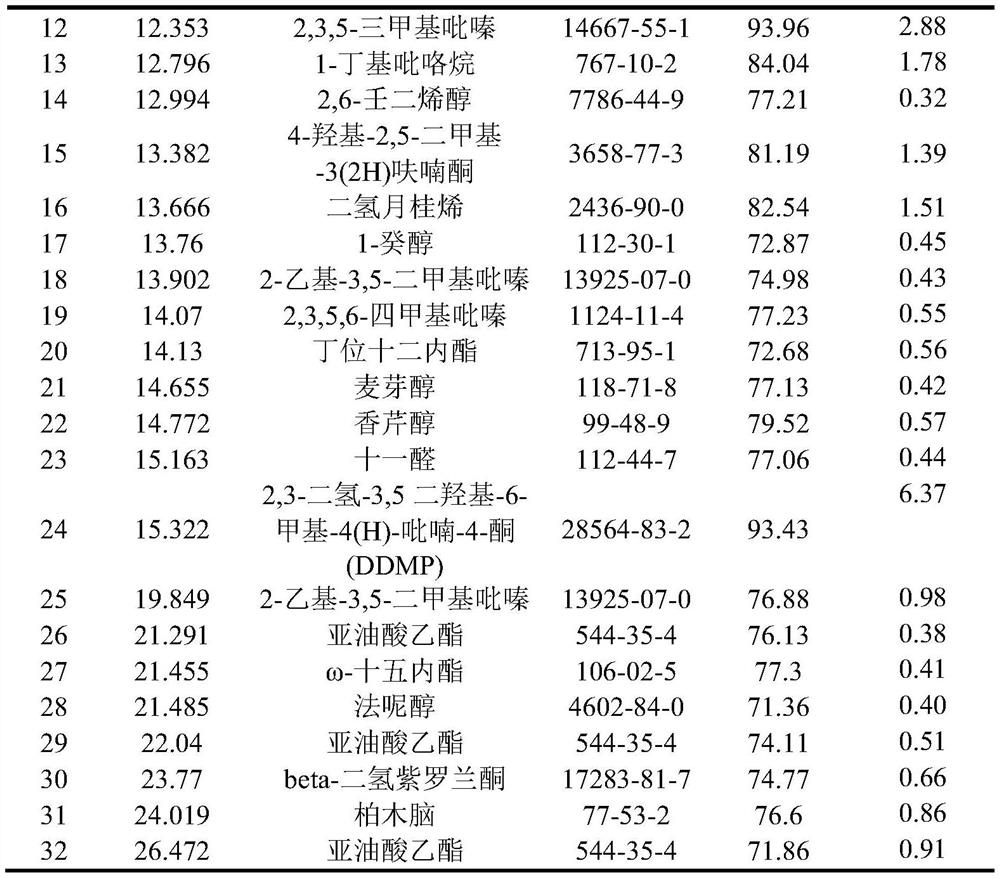

[0069] The lotus seeds were removed from the core, dried in an oven at 50° C. for 3 hours, and crushed to 60 mesh by a pulverizer to obtain lotus seed powder. Take 100g lotus seed powder, add 20 times the volume of citric acid buffer solution, and extract by ultrasonic at 150kw at 25°C for 60min. After the sample was cooled to room temperature, the pH was adjusted to 5, and a composite enzyme consisting of α-amylase, saccharification enzyme, cellulase, and hemicellulase was added, and the amount added was 24wt% of lotus seed powder: 30wt%: 18wt%: 18wt% %, enzymatically hydrolyzed at 60 °C for 8 hours, and the measured sugar rate after enzymatic hydrolysis was 61.46%. Subsequently, the enzyme was inactivated and sterilized in a 100° C. boiling water bath, and then returned to normal temperature, and then centrifuged at 4000 rpm for 30 min. The supernatant was concentrated under reduced pressure, the temperature of the con...

Embodiment 2

[0089] 【Preparation of lotus seed Maillard reactant】

[0090] The lotus seeds were removed from the core, dried in an oven at 45°C for 4 hours, and crushed to 20 mesh by a pulverizer to obtain lotus seed powder. Take 100g lotus seed powder, add 10 times the volume of citric acid buffer solution, and extract by ultrasonic at 100kw at 40°C for 20min. After the sample was cooled to room temperature, the pH was adjusted to 4, and a composite enzyme composed of α-amylase, saccharification enzyme, cellulase, and hemicellulase was added, and the addition amount was 24wt% of lotus seed powder: 30wt%: 18wt%: 18wt% %, enzymatically hydrolyzed for 2 hours at 40 °C, and the sugar rate was 55.58% after enzymatic hydrolysis. Subsequently, the enzyme was inactivated and sterilized in a 100°C boiling water bath, and then returned to normal temperature, and then centrifuged at 10,000 rpm for 15 min. The supernatant was concentrated under reduced pressure, the temperature of the concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com