Preparation method of aluminum alloy material for polished aluminum and aluminum alloy material thereof

An aluminum alloy material and alloy technology, applied in the field of aluminum alloy materials, can solve the problems of reduced material ductility, product surface damage, increased fracture incidence, etc., to reduce fracture incidence, excellent acid and alkali corrosion resistance, and excellent high temperature resistance. The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

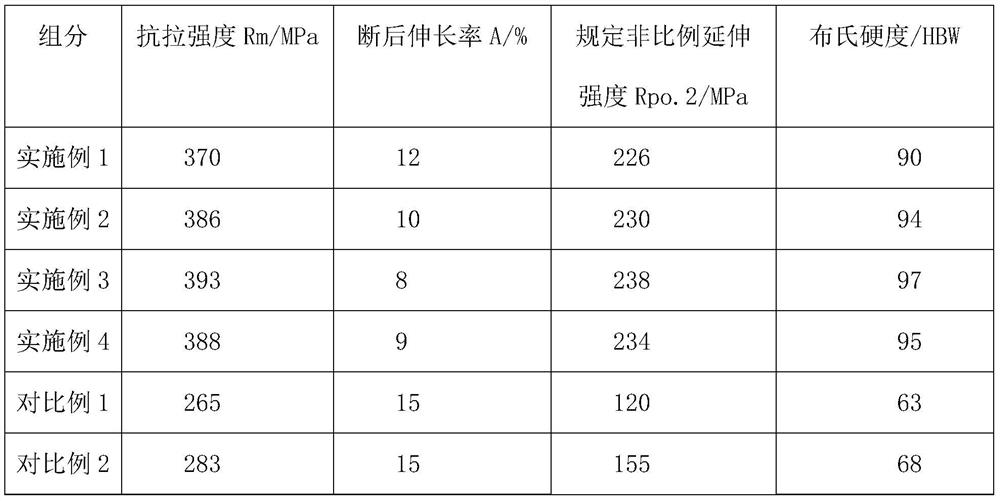

Examples

Embodiment 1

[0036] An aluminum alloy material for polishing aluminum is prepared by the following preparation method, comprising the following steps:

[0037] Step 1: Pretreatment: Mix Mg powder and Si powder into a high-energy ball mill for ball milling. The ball milling rate is 300 r / min. The ball milling medium is quenched steel balls. The ratio of ball to material is 18:1. 6.5mm, after ball milling for 1 hour under the protection of high-purity argon, adding reinforcing powder, and continuing ball milling for 1 hour to obtain Mg-Si composite powder; the reinforcing powder is composed of Fe powder, Cu powder, Mn powder, Cr powder, Ti powder, Zn powder With a mass ratio of 5:1:1:1:2:1, the content of reinforcing powder accounts for 0.1% of the total weight of the Mg-Si composite powder;

[0038]Step 2: Preparation of liquid alloy: Put the Mg-Si composite powder into the melting furnace to melt, smelt at 800°C, add Al powder after complete melting to obtain an alloy system, and keep the ...

Embodiment 2

[0048] An aluminum alloy material used for polishing aluminum is prepared by the following preparation method, comprising the following steps:

[0049] Step 1: Pretreatment: Mix Mg powder and Si powder into a high-energy ball mill for ball milling. The ball milling rate is 320 r / min. The ball milling medium is quenched steel balls. The ratio of ball to material is 16:1. The diameter of the quenched steel ball is 6.5mm, after ball-milling for 1h under the protection of high-purity argon gas, adding reinforcing powder and continuing ball-milling for 1h to obtain Mg-Si composite powder; the reinforcing powder is composed of Fe powder, Cu powder, Mn powder, Cr powder, Ti powder, Zn powder With a mass ratio of 3:1:1:1:1:1, the content of reinforcing powder accounts for 0.2% of the total weight of the Mg-Si composite powder;

[0050] Step 2: Preparation of liquid alloy: put the Mg-Si composite powder into the melting furnace to melt, smelt at 800°C, add Al powder after complete melt...

Embodiment 3

[0060] An aluminum alloy material used for polishing aluminum is prepared by the following preparation method, comprising the following steps:

[0061] Step 1: Pretreatment: Mix Mg powder and Si powder into a high-energy ball mill for ball milling. The ball milling rate is 350 r / min. The ball milling medium is quenched steel balls. The ratio of ball to material is 15:1. The diameter of the quenched steel ball is 6.5mm, after ball-milling for 1h under the protection of high-purity argon gas, adding reinforcing powder and continuing ball-milling for 1h to obtain Mg-Si composite powder; the reinforcing powder is composed of Fe powder, Cu powder, Mn powder, Cr powder, Ti powder, Zn powder With a mass ratio of 10:1:1:1:2:1, the content of reinforcing powder accounts for 0.08% of the total weight of the Mg-Si composite powder;

[0062] Step 2: Preparation of liquid alloy: put the Mg-Si composite powder into the melting furnace to melt, smelt at 800°C, add Al powder after complete me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com