Power battery system, electric vehicle and design method

A technology of power battery and design method, which is applied in the direction of secondary battery, battery pack components, secondary battery repair/maintenance, etc., and can solve the problems of easy damage of battery cells, time-consuming and labor-intensive, affecting the weight and cost of the whole vehicle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

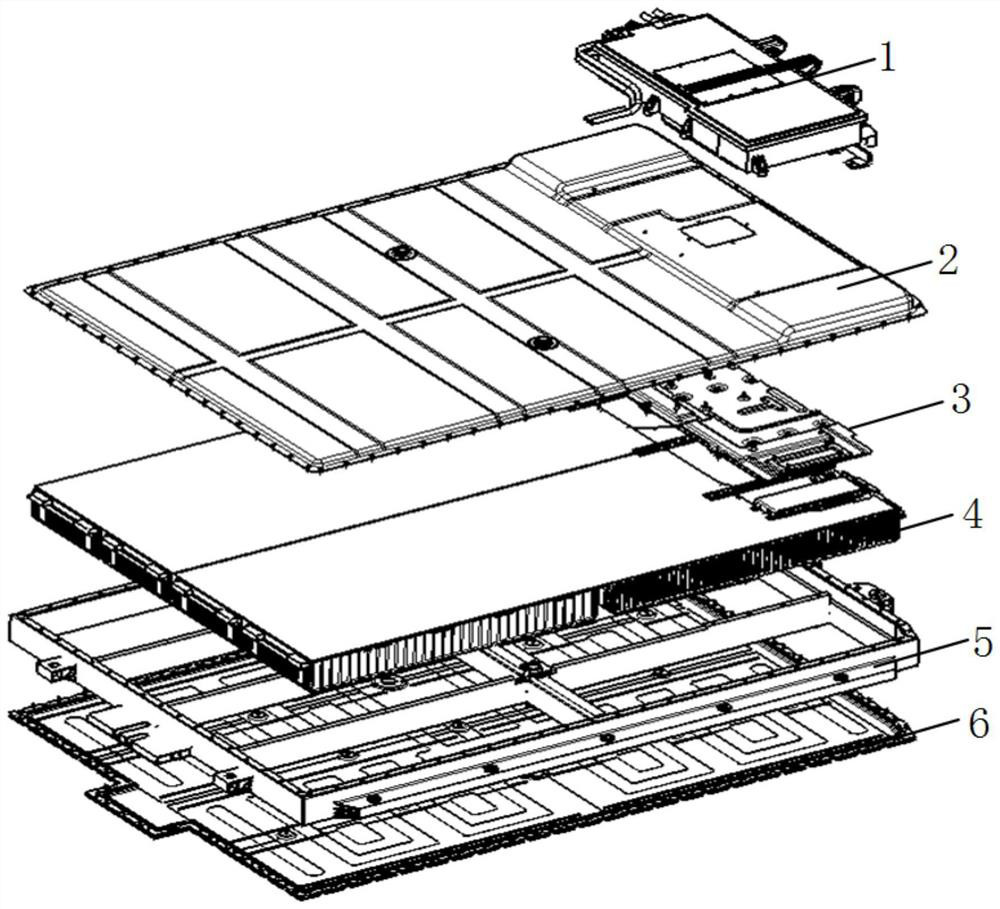

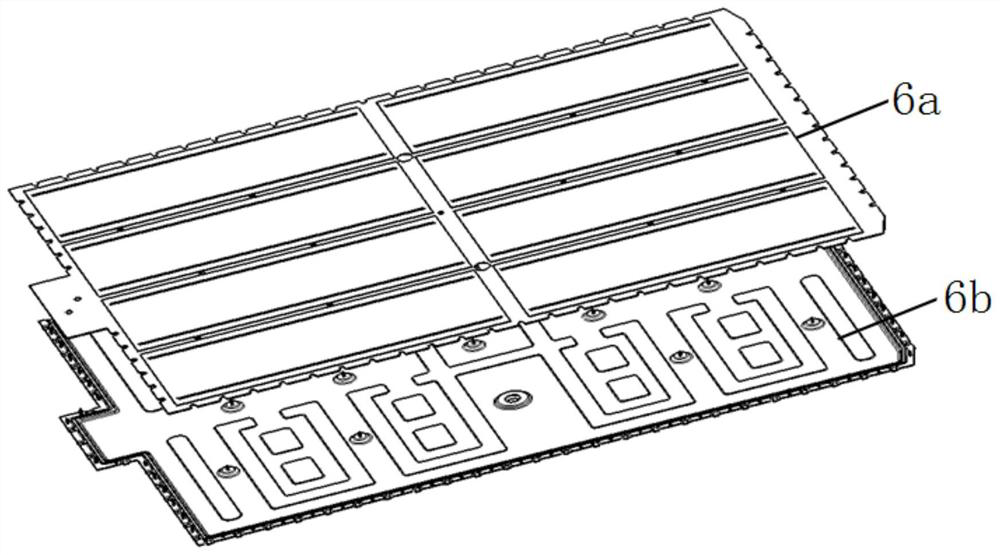

[0049] see Image 6 , a power battery system, including an energy management unit 1 and a power battery unit.

[0050] The energy management unit 1 includes a power supply device, a control device and a power distribution device.

[0051] The power battery unit includes an energy storage device, a thermal management device and a sampling device.

[0052] Through the integration of the energy management unit and the power battery unit, the high integration of the high-voltage system is realized, and the weight reduction and cost reduction at the vehicle level are realized.

[0053]The power distribution device is connected in series between the high-voltage interface of the power battery unit and the DC bus interface of the electrical device; the power distribution device and the control device are connected through a low-voltage wire harness; the control device provides an action signal of the power distribution device, and the power distribution The device action realizes o...

Embodiment 2

[0062] An electric vehicle includes a power battery system, that is, an energy management unit 1 and a power battery unit. The energy management unit 1 includes a power supply device, a control device and a power distribution device. The power battery unit includes an energy storage device, a thermal management device and a sampling device. The power distribution device is connected in series between the high-voltage interface of the power battery unit and the DC bus interface of the electrical device; the power distribution device and the control device are connected through a low-voltage wire harness; the control device provides an action signal of the power distribution device, and the power distribution The device action realizes opening and closing; the energy storage device is fixed on the thermal management device; the sampling device and the energy storage device are connected by a low-voltage wire harness to realize signal transmission. The electric vehicle including...

Embodiment 3

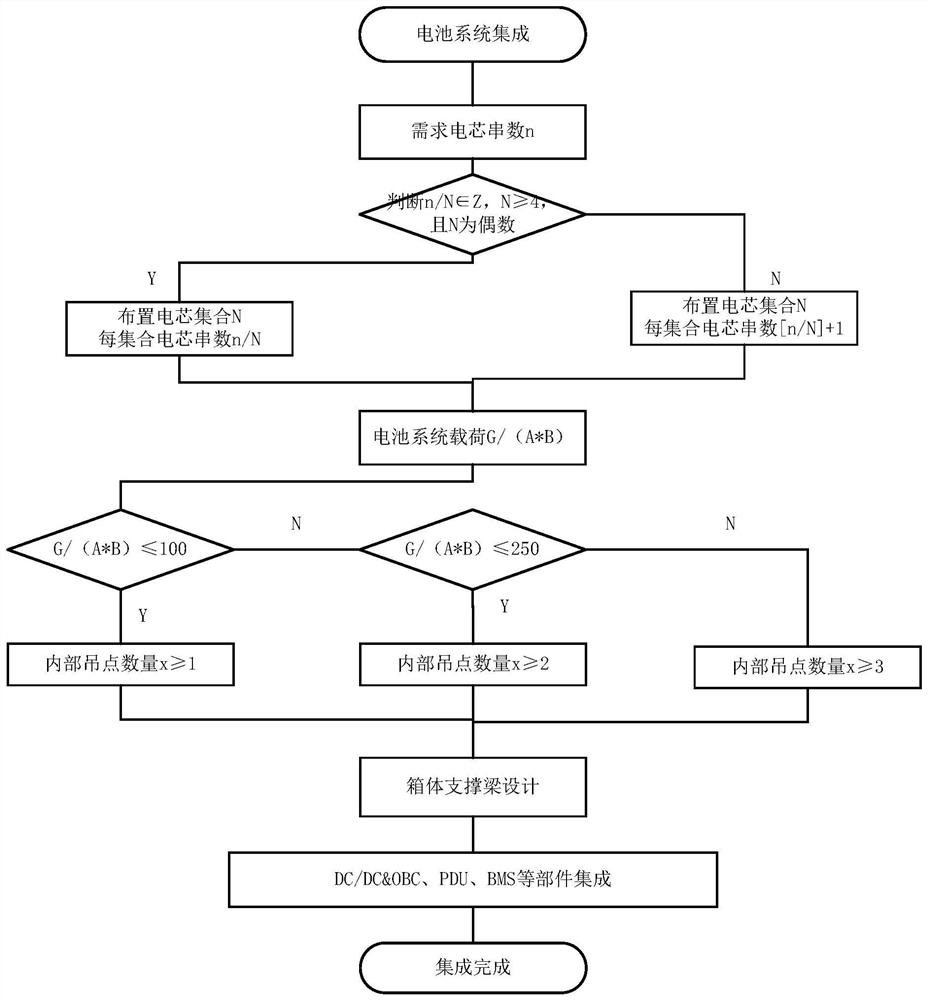

[0064] see image 3 , a design method of a power battery system for designing a power battery system, including the following steps:

[0065] Step 1, arranging the battery cell set 4 in the power battery unit;

[0066] see Figure 4 , the specific method of the step one is as follows:

[0067] Place the fuse on the output pole side of the DC bus, and set 1, 2, 3...N of battery cells to meet the following requirements:

[0068] U 1 +……+U N / 2 =U N / 2+1 +……+U N =U O / 2, where N is even and N≥4;

[0069] Among them, N is the number of cell sets; U N is the output terminal voltage of the cell set N; U O is the DC bus output voltage.

[0070] The battery cell set 4 includes a variety of battery cell forms such as square shell cells, soft-packed cells, and cylindrical cells.

[0071] The cell sets are arranged in 4 even-numbered columns, and fuses are connected in series between sets N / 2 and N / 2+1, including excitation fuses, intelligent fuses and other fuses that can inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com