Method and system for producing gasoline blend oil by using C5 raffinate oil

A technology for raffinate oil and blended oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc. It can solve the problem of single processing route of ethylene carbon five raffinate oil, achieve rich processing methods, save investment and operating costs , the effect of low sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

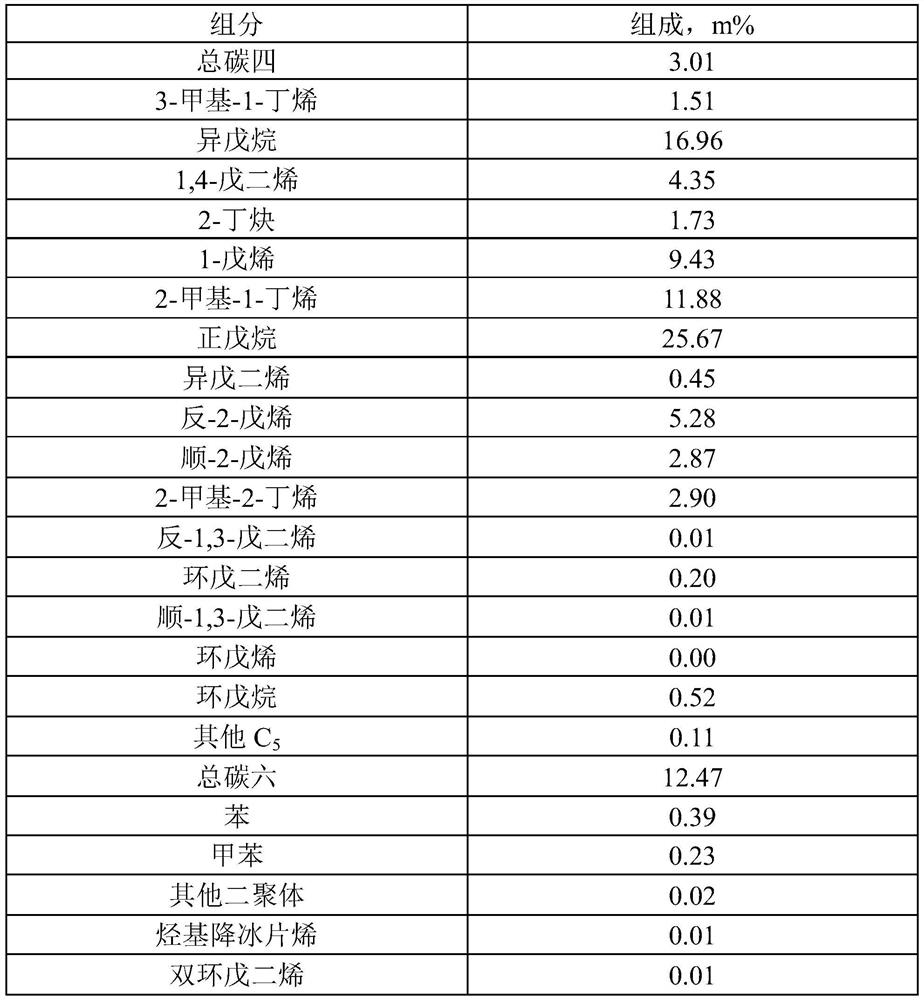

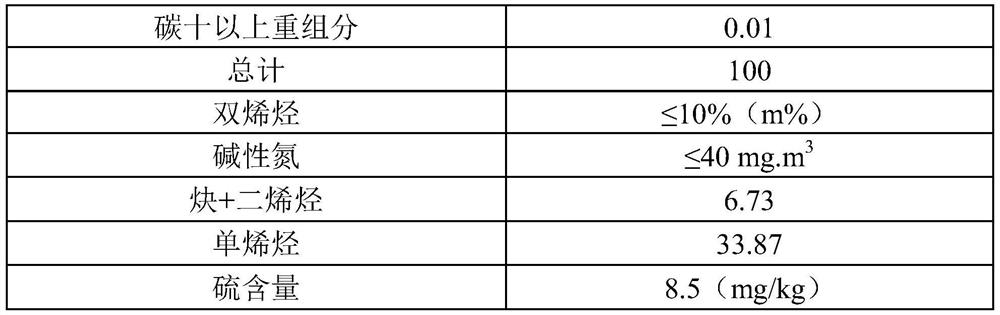

[0071] This example is used to illustrate the method for producing gasoline blend oil using C5 raffinate provided by the present invention

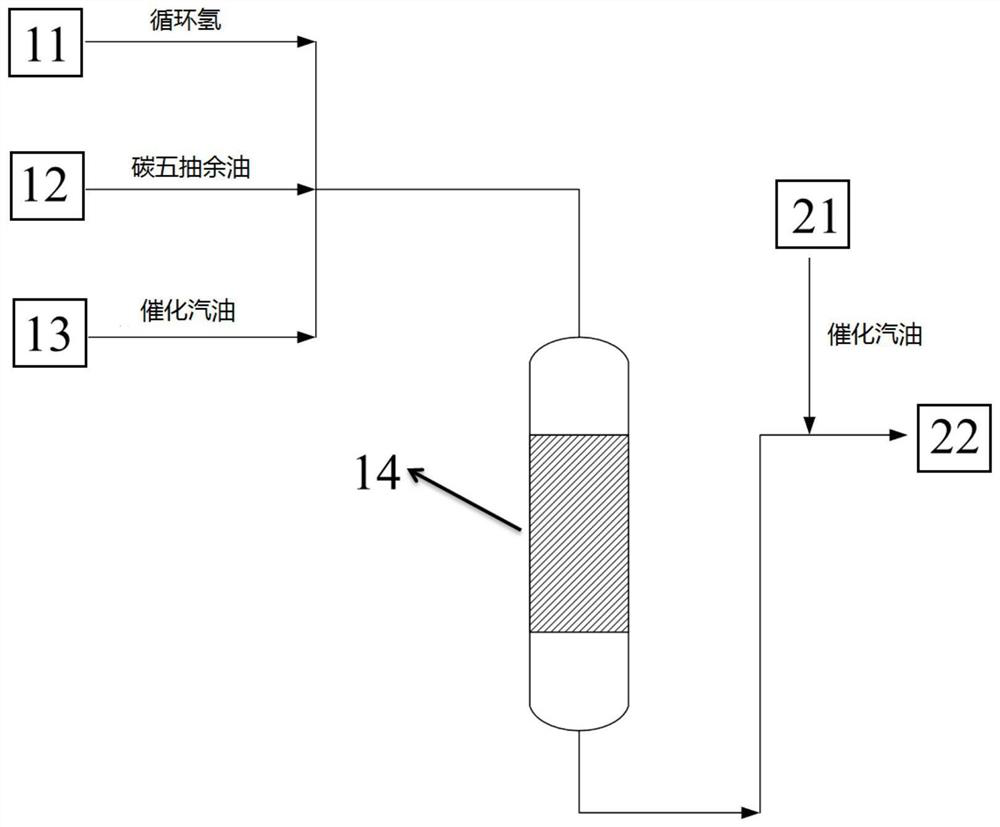

[0072] According to the setting in Table 4, one route of circulating hydrogen is drawn from the S Zorb device, mixed with the C5 raffinate and part of the catalytic gasoline raw material, and then enters the pre-hydrogenation reactor to carry out the pre-hydrogenation reaction. The properties of the pre-hydrogenated material are as follows: As shown in Table 6, after the diolefins are converted into monoolefins, they are mixed with the remaining catalytic gasoline feedstock into the S Zorb unit for adsorption and desulfurization to obtain high-standard gasoline. The sulfur content, octane number, sulfur removal rate and Table 7 shows the refined gasoline octane loss relative to the catalytic gasoline feedstock.

[0073] The output of the above-mentioned pre-hydrorefined materials after mixing is about 600,000 tons / year, and then enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap