Efficient automatic cleaning device for distillation passage of U-shaped titanium sponge reactor

An automatic cleaning and sponge titanium technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult control of cleaning smoke and dust, impact on product quality, air intake of sponge titanium, etc., and achieve air isolation effect Easy to lift, install and lift, and ensure airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

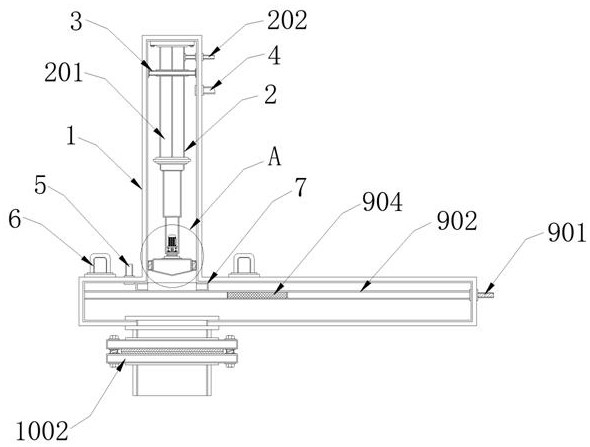

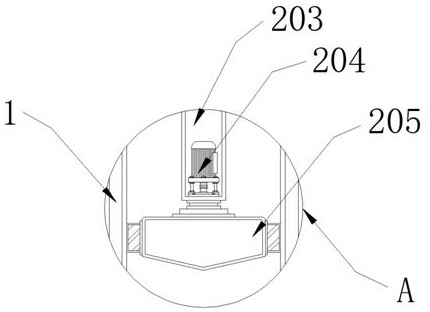

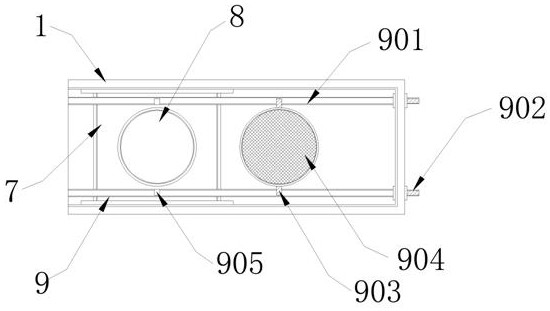

[0026] see Figure 1-4 , the present invention provides a technical solution: a high-efficiency automatic cleaning device for the distillation aisle of a U-shaped titanium sponge reactor, comprising a casing 1, a cleaning assembly 2 and a partition assembly 9, the inner top of the casing 1 is arranged with a cleaning assembly 2, and the cleaning assembly 2. It includes a hydraulic cylinder 201, a first hydraulic connection valve 202, a push-out rod 203, a motor 204 and a high-strength drill bit 205. The outer end of the hydraulic cylinder 201 is connected with a first hydraulic connection valve 202, and the inner side of the hydraulic cylinder 201 is provided with a push-out rod 203, the inner front end of the push rod 203 is connected with a motor 204, and the output end of the motor 204 is provided with a high-strength drill bit 205, the outer middle end of the hydraulic cylinder 201 is connected with a sealing plate 3, and the top middle end of the housing 1 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com