Intelligent welding device for aloft work

A welding device and high-altitude operation technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of manual operation danger, inability to ensure personal safety, inconvenience, etc., and achieve the effect of avoiding personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

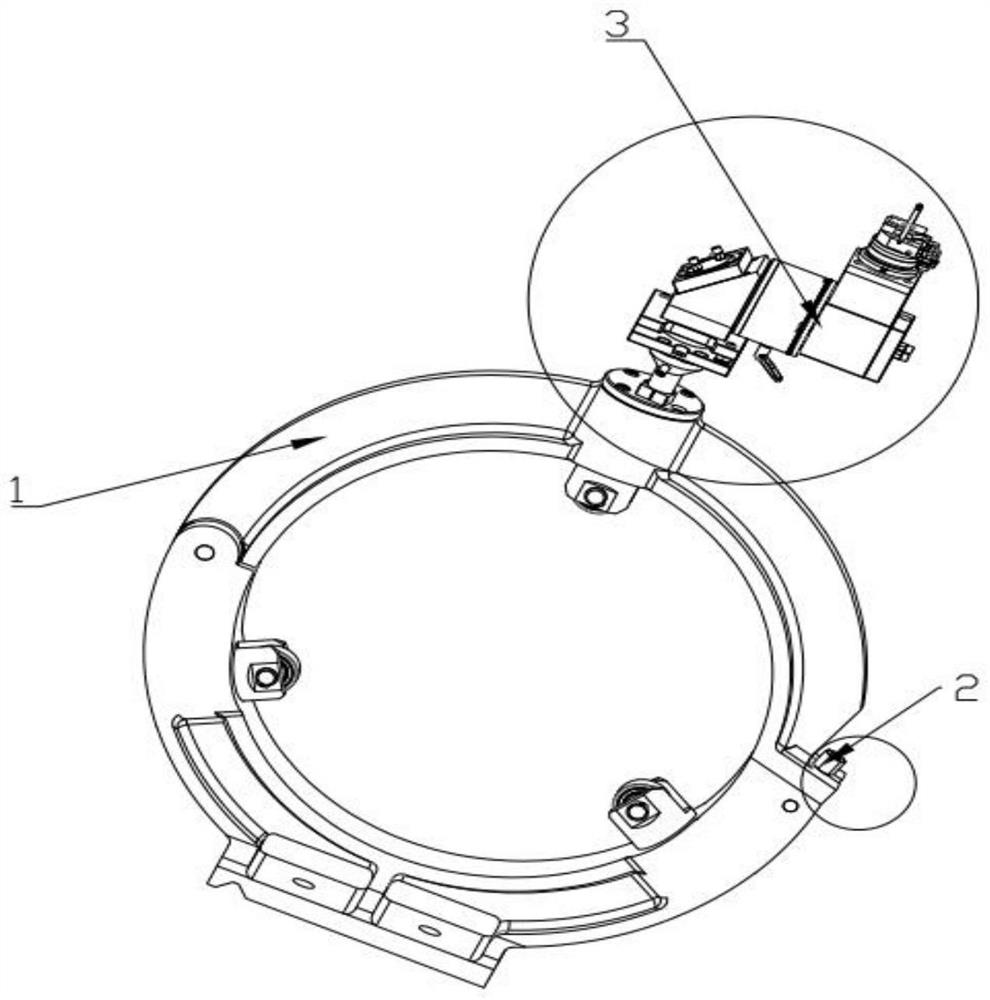

[0020] The intelligent welding device for aerial work proposed in this embodiment includes two components: a clamping part and a welding part 3 . The clamping part includes two components: a telescopic plate 1 and a locking device 2 . The telescopic plate 1 has a predetermined bending arc for wrapping and fixing the workpiece to be welded; the lock 202 device 2 is connected to the telescopic plate 1 for wrapping the telescopic plate 1 after the workpiece is wrapped. Lock and fix. The welding part 3 includes three parts: a bearing device, an adjusting device and a welding device; the bearing device is slidably connected with the telescopic plate 1 for the connection between the welding part 3 and the clamping part; the adjustment The device is connected with the bearing device, and is used for adjusting the working point of the overall welding operation of the welding part 3; the welding device is connected with the adjusting device, and is used for welding the workpiece. The...

Embodiment 2

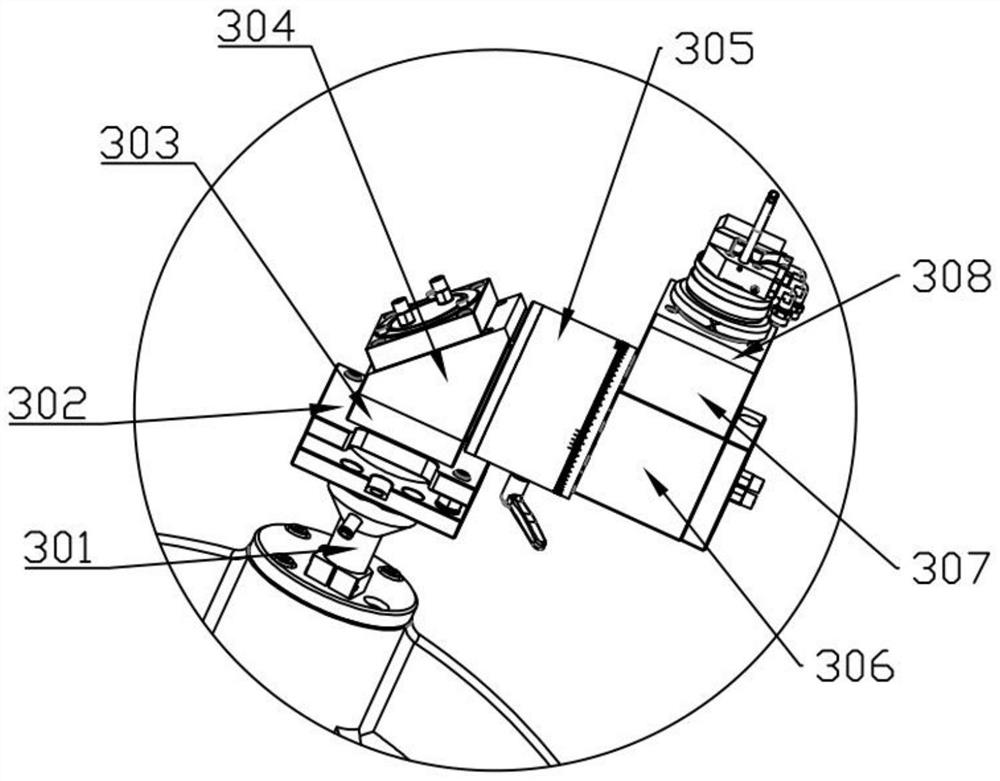

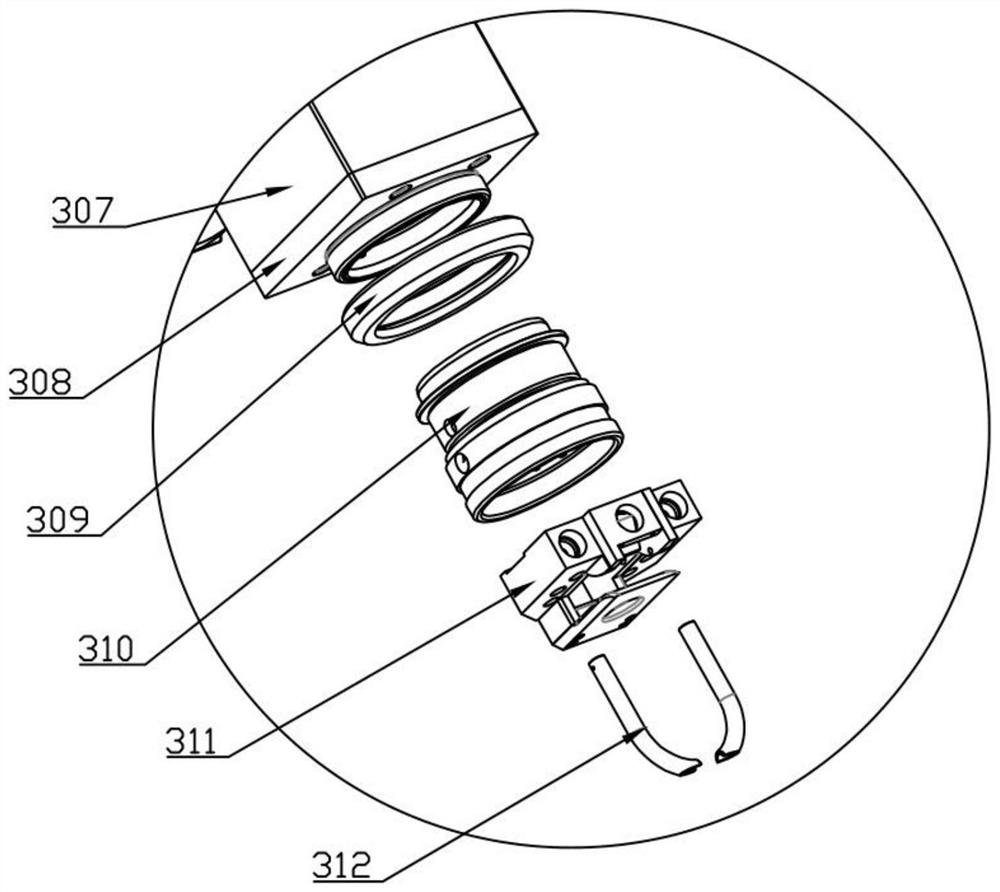

[0022] On the basis of the first embodiment, the bearing device includes three components: the sliding column 301 , the backing plate 302 and the connecting plate 303 . One end of the sliding column 301 is slidably connected with the telescopic plate 1, and has the flexibility of reciprocating sliding along the surface of the telescopic plate 1; The flexibility of the sliding column 301 to move; the connecting plate 303 is fixedly connected with the backing plate 302 on one side, and is used for the mutual connection between the bearing device and the adjusting device. The adjusting device includes three components: a base 304 , a rotating seat 305 and a rotating disk 306 . One side of the base 304 is fixedly connected with the connecting plate 303 for the overall positioning of the adjusting device; Sliding flexibility; the rotating disk 306 is pivotally connected to the other surface of the rotating base 305 , and has the flexibility to rotate in all directions around the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com