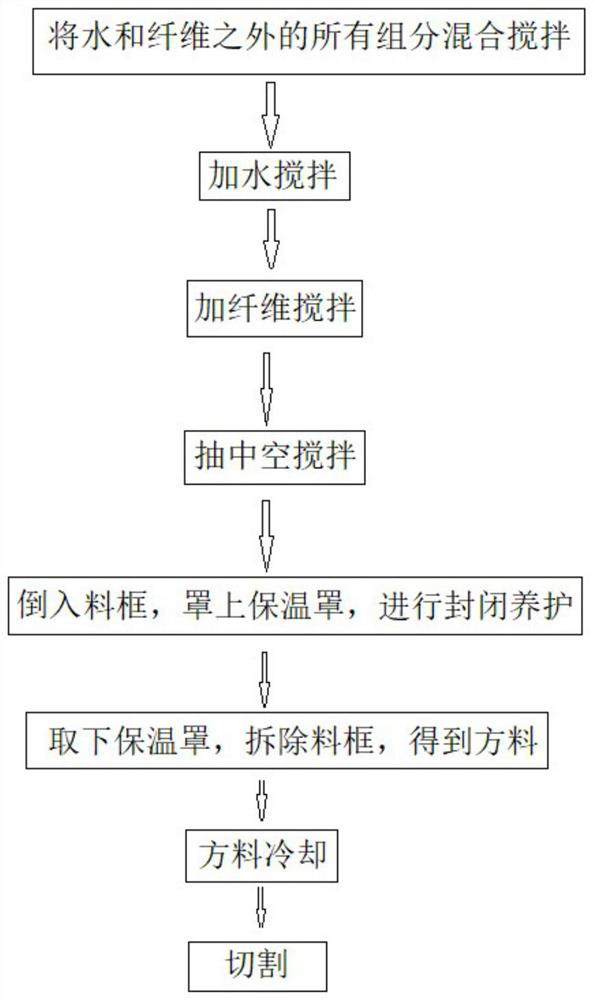

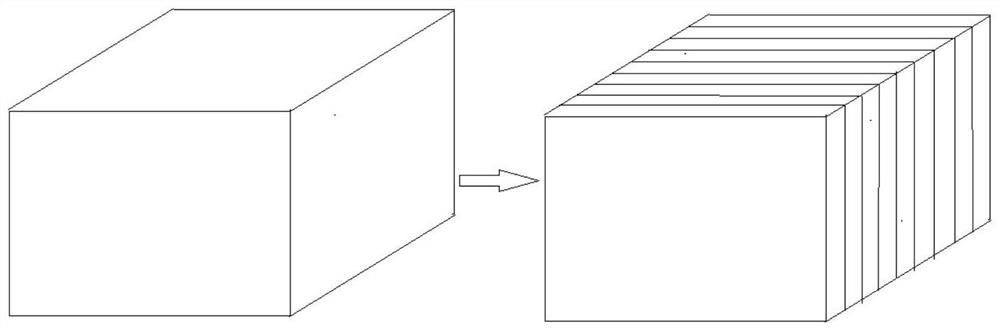

Production process and formula of fiber reinforced cement board based on square stock cutting method

A technology of fiber reinforcement and production process, which is applied in the field of production technology and formulation of fiber reinforced cement board, can solve the problems of fast expansion at the edge of fiber reinforced cement board, broken edge of fiber cement board, and reduced quality of fiber cement board, etc. Achieve the effect of reducing the loss of water and cement hydration heat, avoiding shrinkage and deformation, and avoiding product cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a fiber-reinforced cement board, which includes, in parts by weight, 180 parts of water, 590.45 parts of cement, 45.2 parts of high ground, 410.66 parts of heavy calcium powder, 1219 parts of calcium carbonate sand, 28 parts of fiber, and a water reducer. 6 parts, 1 part of defoamer, and 0.4 part of retarder, among which, the volume of cement slurry other than calcium carbonate sand and fibers accounts for 52%.

[0048] Among them, the cement is the cement with the grade of 42.5 or higher. The median particle size D50 of the high territory is between 600 mesh and 5000 mesh. The median particle size D50 of heavy calcium powder is between 200 mesh and 5000 mesh. The particle size range of the calcium carbonate sand is 4 meshes to 100 meshes. The fiber is one of polypropylene fiber, copolyformaldehyde fiber, ultra-high molecular weight polyethylene fiber, and polyvinyl alcohol fiber. The water reducing agent is a polycarboxylate water reducing a...

Embodiment 2

[0060] This embodiment provides a fiber-reinforced cement board, which includes, in parts by weight, 190 parts of water, 610.10 parts of cement, 42.3 parts of high ground, 350 parts of heavy calcium powder, 1155.56 parts of calcium carbonate sand, 18 parts of polypropylene fibers, 8 parts of water agent, 2 parts of defoamer, 0.6 part of retarder.

[0061] Among them, the cement is the cement with the grade of 42.5 or higher. The median particle size D50 of the high territory is between 2000 mesh and 4000 mesh. The median particle size D50 of heavy calcium powder is between 300 mesh and 1500 mesh. The median particle size D50 of calcium carbonate sand is between 40 mesh and 100 mesh. The fibers are in co-polyacetal fibers. The water reducing agent is a polycarboxylate water reducing agent. The defoamer is a silicone defoamer, and the retarder is sodium gluconate.

[0062] The above production process is the same as that of Example 1.

Embodiment 3

[0064] This embodiment provides a fiber-reinforced cement board, which includes, in parts by weight, 210 parts of water, 580.86 parts of cement, 55 parts of high ground, 434.77 parts of heavy calcium powder, 1273.28 parts of calcium carbonate sand, 12 parts of polypropylene fibers, 10 parts of water agent, 3 parts of defoamer, 0.3 part of retarder.

[0065] The specifications of the above raw materials are the same as in Example 1, and the production process is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com