Low-warpage reinforced PBT/ASA material and preparation method thereof

A low-warpage, ASA resin technology, applied in the field of polymer materials, to achieve the effect of convenient use and easy procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

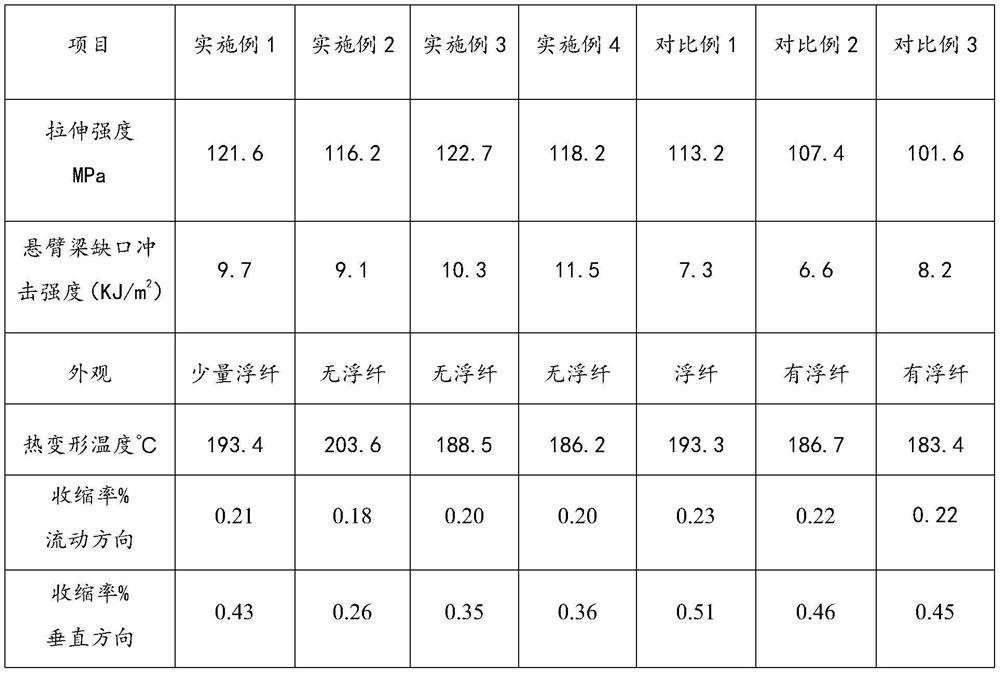

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below with reference to specific embodiments. The examples are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0019] The methods adopted in the present invention are conventional methods unless otherwise specified, and the raw materials used in the present invention are all domestic commercial products. Specifically, the PBT resin is starester1072 produced by Nantong Xingchen Company by the PTA method; the PET resin is SB500 of Yizheng Chemical Fiber, the AS in the ASA resin is Ningbo Taihua NF2200, the high rubber powder is Shanghai Muyan 600; the compatibilizer is Jiaxing Huawen The HW320 and HW330 produced; the round chopped glass fiber is ECS10-3-T436H of Taishan Company and the flat is ECS301HP-3-M4 of Chongqing International Composite Materials; the toughening agent is Nengzhiguang E515, and the auxiliary agent including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com