Coated modified zinc powder and preparation method thereof

A zinc powder and modification technology, which is applied in coatings, anti-corrosion coatings, etc., can solve problems such as waste and coating service life not reaching the theoretical value, and achieve the effects of reducing activation energy, reducing over-activation, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

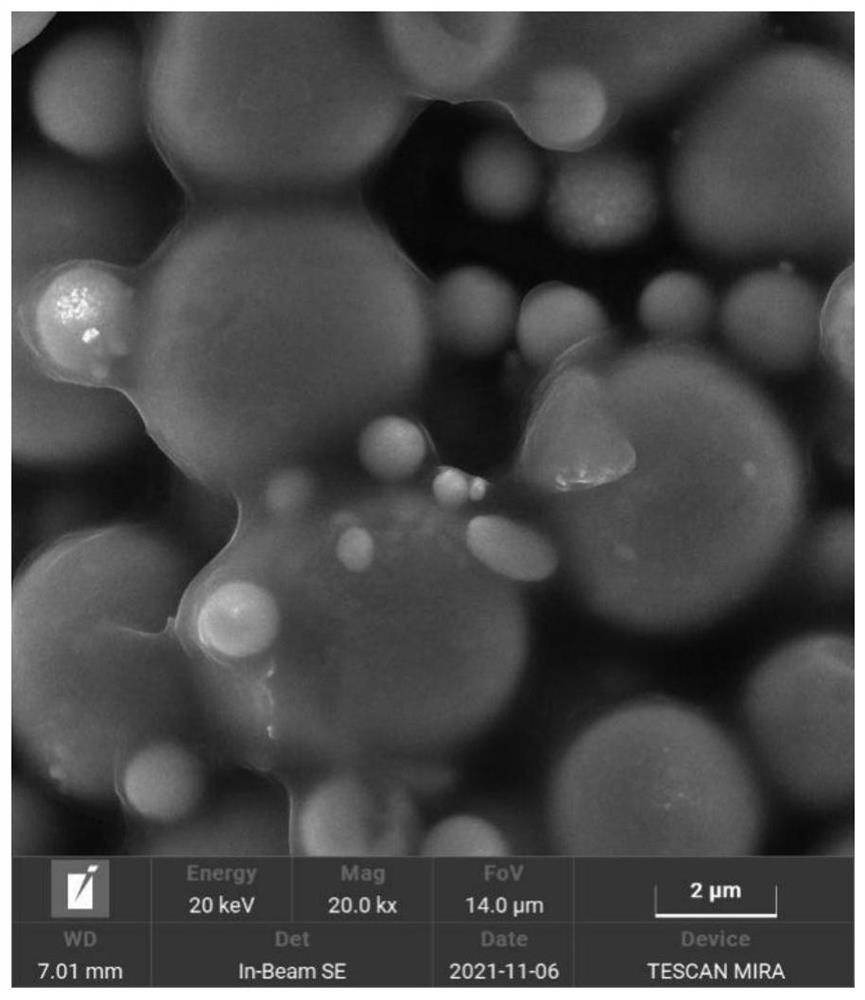

[0040] The coating modified zinc powder in this embodiment is a zinc powder coated with a nano zinc oxide film, the particle size of the zinc powder is 1200 mesh, and the thickness of the nano zinc oxide film is 10 nm. figure 1 The scanning electron microscope image of the coated modified zinc powder of the present embodiment, through figure 1 It can be seen that the zinc powder is covered by a zinc oxide shell with a thickness of 10 nm.

[0041] The preparation method of the present embodiment is as follows:

[0042] (1) 4g urea and 21g deionized water were prepared into urea solution, and 5g zinc nitrate (containing 3.45g zinc ion) and 20g deionized water were prepared into zinc ion solution;

[0043] (2) Add 0.5 g of surfactant OP-10 into the urea solution, and after stirring evenly, put the urea solution containing the surfactant into the three-necked flask; connect the three-necked flask to the heating device and the vacuuming device; turn on the stirrer , the rotating ...

Embodiment 2

[0050] The coating-modified zinc powder in this embodiment is a zinc powder coated and modified by a nano-zinc oxide film, the particle size of the zinc powder is 1000 mesh, and the thickness of the nano-zinc oxide film is 15 nm.

[0051] The preparation method of the present embodiment is as follows:

[0052] (1) 6g urea and 24g deionized water were prepared into urea solution, and 8g zinc chloride (containing 3.84g zinc ion) and 22g deionized water were prepared into zinc ion solution;

[0053] (2) Add 0.5g of surfactant OE-20 to the urea solution, and after stirring evenly, put the urea solution containing the surfactant into the three-necked flask; connect the three-necked flask to the heating device and the vacuuming device; turn on the stirrer , the rotation speed is 500r / min, and the zinc ion solution is slowly added (the addition process takes 8min); the heating device is turned on, the stirring is continued, the temperature is raised to 90°C, and the reaction is maint...

Embodiment 3

[0057] The coated and modified zinc powder in this embodiment is a zinc powder coated and modified by a nano-zinc oxide film, the particle size of the zinc powder is 1500 mesh, and the thickness of the nano-zinc oxide film is 10 nm.

[0058] The preparation method of the present embodiment is as follows:

[0059] (1) 3.5g of urea and 24g of deionized water were prepared into a urea solution, and 4g of zinc chloride (containing 1.92g of zinc ions) and 22g of deionized water were prepared into a zinc ion solution;

[0060] (2) Add 0.5g of surfactant OE-20 to the urea solution, and after stirring evenly, put the urea solution containing the surfactant into the three-necked flask; connect the three-necked flask to the heating device and the vacuuming device; turn on the stirrer , the rotating speed is 450r / min, and the zinc ion solution is slowly added (the addition process takes 10min); the heating device is turned on, the stirring is continued, the temperature is raised to 80°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com