Phase-change nanocapsule composite material with enhanced heat conductivity as well as preparation method and application of phase-change nanocapsule composite material

A technology of nanocapsules and composite materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of unstirable rubber materials and uneven dispersion of polymers, and achieve reduced material hardness, high thermal conductivity, and large Effect of specific surface area on heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

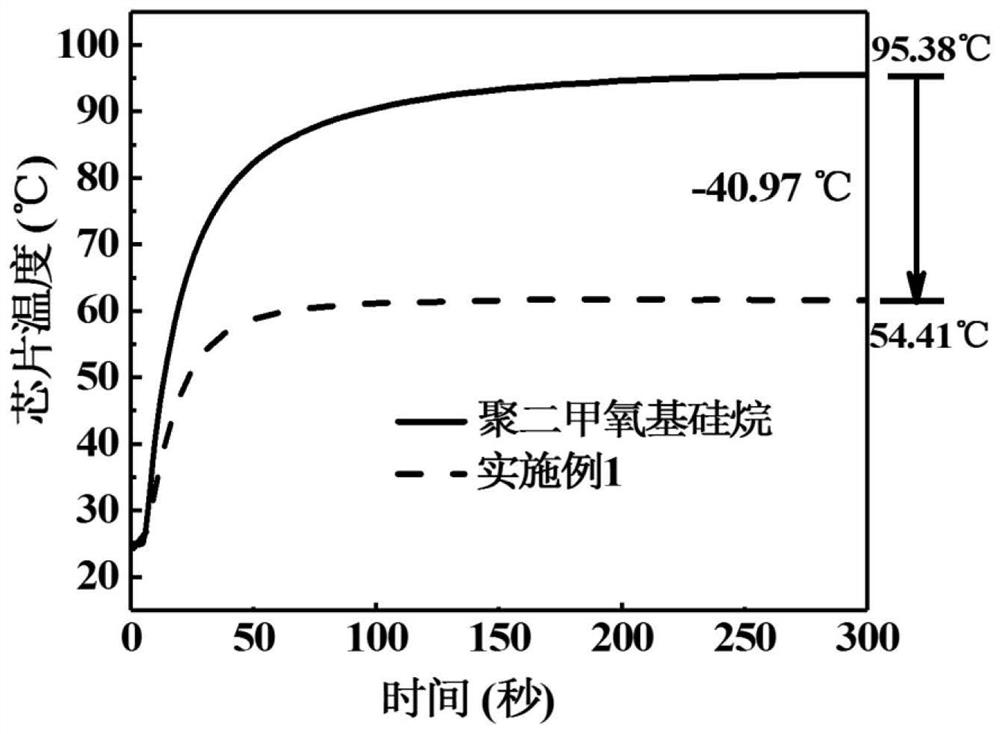

Embodiment 1

[0033] A thermal conductivity-enhanced phase-change nanocapsule composite material, calculated in mass fraction, is made from the following raw materials: inorganic shell phase-change nanocapsules 10.53%, high thermal conductivity filler boron nitride 31.58%, polydimethylsiloxane pre- Polymer 52.63% and hydrogen silicone oil 5.26%.

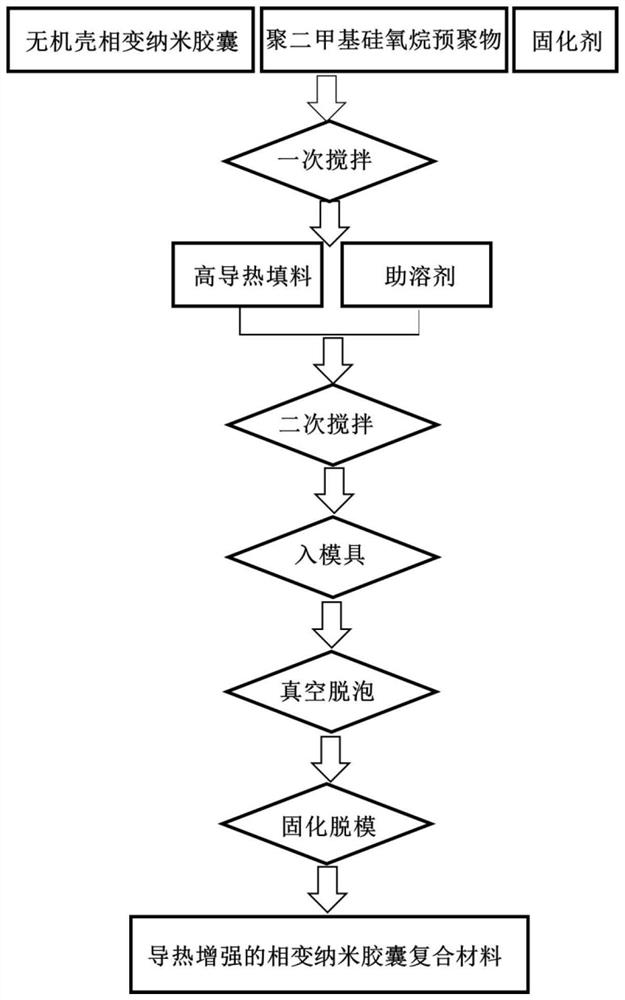

[0034]The preparation method of the phase-change nanocapsule composite material with enhanced thermal conductivity comprises the following steps:

[0035] (1) The phase-change nanocapsules with paraffin as the core material and silica as the shell material were prepared by the interfacial hydrolysis-polycondensation method: paraffin (15.0g), tetraethyl orthosilicate TEOS (7.5g) were placed in a 250mL three-necked flask with Stir and mix at 60°C to form a clear solution. Then, simultaneously, cetyltrimethylammonium bromide CTAB (0.82 g), deionized water (35.5 mL) and absolute ethanol (71.25 mL) were added to a 250 mL beaker and incubated to 60°C. ...

Embodiment 2

[0042] A thermal conductivity-enhanced phase-change nanocapsule composite material, calculated in mass fraction, is made from the following raw materials: inorganic shell phase-change nanocapsules 19.05%, high thermal conductivity filler boron nitride 28.57%, polydimethylsiloxane pre- Polymer 47.62% and hydrogen siloxane 4.76%.

[0043] The preparation method of the phase-change nanocapsule composite material with enhanced thermal conductivity comprises the following steps:

[0044] (1) The phase-change nanocapsules with paraffin as the core material and silica as the shell material were prepared by the interfacial hydrolysis-polycondensation method: paraffin (15.0g), tetraethyl orthosilicate TEOS (7.5g) were placed in a 250mL three-necked flask with Stir and mix at 60°C to form a clear solution. Then, simultaneously, cetyltrimethylammonium bromide CTAB (0.82 g), deionized water (35.5 mL) and absolute ethanol (71.25 mL) were added to a 250 mL beaker and incubated to 60°C. Th...

Embodiment 3

[0051] A thermal conductivity-enhanced phase-change nanocapsule composite material, calculated in mass fraction, is made from the following raw materials: inorganic shell phase-change nanocapsules 26.09%, high thermal conductivity filler boron nitride 26.09%, polydimethylsiloxane pre- Polymer 43.47% and methyl hydrogen silicone oil 4.35%.

[0052] The preparation method of the phase-change nanocapsule composite material with enhanced thermal conductivity comprises the following steps:

[0053] (1) The phase change nanocapsules with paraffin as the core material and silica as the shell material were prepared by the interfacial hydrolysis-polycondensation method: paraffin (15.0g), tetraethyl orthosilicate TEOS (7.5g) were placed in a 250mL three-neck flask with Stir and mix at 60°C to form a clear solution. Then, simultaneously, cetyltrimethylammonium bromide CTAB (0.82 g), deionized water (35.5 mL) and absolute ethanol (71.25 mL) were added to a 250 mL beaker and incubated to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com