Preparation method of Tibetan tea beer

A technology for beer and Tibetan tea, which is applied in beer fermentation methods, alcoholic beverage preparation, beer brewing, etc., can solve the problems of large adsorption degree and reduced foam retention, and achieves improved clarity, reduced dust pollution, and increased flavor. and functional ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

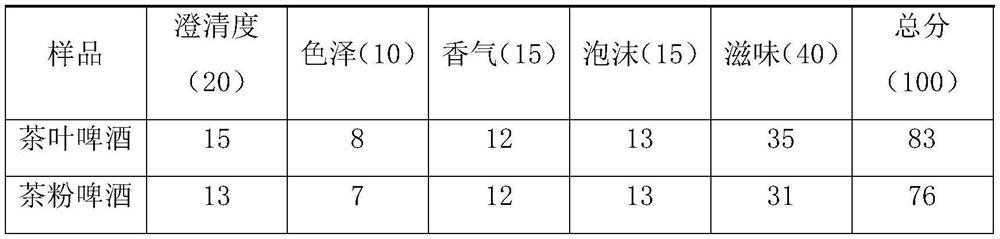

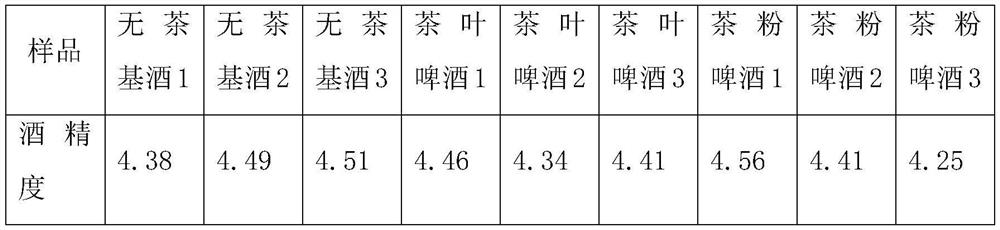

[0048] Example 1: The difference experiment of adding tea leaves and tea powder during wort saccharification

[0049] A Tibetan tea beer, the ingredients of which include by weight:

[0050] 3300 parts of water, 500 parts of malt, 10 parts of ultra-fine tea powder, 4 parts of hops, 1 part of yeast.

[0051] The preparation steps are as follows:

[0052] 1. Pulverized malt: Pulverize 500 parts of malt to 20 mesh with a pulverizer.

[0053] 2. Saccharification: put the crushed malt into the saccharification pot, add 1800 parts of hot water at 50°C for 10min, heat up to 62°C for 30min, then heat up to 68°C for 30min, and finally heat up to 78°C for 50min. If it is not blue, it indicates that the saccharification is completed, and the saccharification solution is obtained.

[0054] 3. Washing the dregs: wash the dregs with 1500 parts of hot water at 75-80°C, filter to obtain mash, and combine the mash in the washing tank with the saccharification solution obtained by saccharifi...

Embodiment 2

[0060] The process conditions and formula in Example 2 are the same as those in Example 1, and the difference is only in the superfine tea powder added in Example 1, which is tea leaves added in Example 2.

Embodiment 3

[0105] A preparation method of Tibetan tea beer, comprising the following steps:

[0106] Step (1) prepares raw material, raw material of the present invention is by weight:

[0107] 500 parts of malt; 10 parts of tea powder; 5 parts of hops; 1 part of yeast powder;

[0108] 2 parts of carrageenan; 6 parts of beer silica gel; 8 parts of PVPP clarifying agent;

[0109] The composition ratio of PVPP clarifying agent is: PVPP 100g, β-cyclodextrin 12g, gellan gum 6g; that is, 12g β-cyclodextrin and 6g gellan gum are added to each 100g PVPP.

[0110] Step (2) pulverizing malt to prepare saccharification solution;

[0111] Pulverize the malt to 20 mesh, put it in a mashing pot, add 1800 parts of water, heat it to 50°C for 12min; then heat it up to 65°C for 30min; finally heat it up to 80°C for 50min; filter after the constant temperature is over, and after filtration Add 80 ℃ of hot water to the malt grains to wash the grains, and combine the filtrates to obtain a saccharificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com