PEO-based solid-state electrolyte, preparation thereof and application of PEO-based solid-state electrolyte in solid-state lithium-sulfur battery

A solid electrolyte and lithium salt technology, which is applied to a polyoxyethylene solid electrolyte, a preparation method thereof, and an application field in a solid lithium-sulfur battery, can solve the problems of unfavorable battery stable cycle, polysulfide dissolution and shuttle, etc. Improved battery safety, uniform Li-ion flux, and loss-avoidance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Weigh 0.4344g lithium bistrifluoromethanesulfonimide (LiTFSI), 0.0050g Mg(TFSI) 2 and 0.1500g β-cyclodextrin were placed in a 100mL flat-bottomed flask, then 12.5000g of acetonitrile solvent (AN) was added, ultrasonicated for 10min at 25°C, stirred for 10min, and after a uniform suspension was formed, 1.0000g of polyethylene oxide ( PEO), stirred at room temperature for 12 hours to obtain a slurry; poured the obtained slurry into a mold, stood for 8 hours until the solvent was completely volatilized, and then transferred to a vacuum drying oven at 60 °C for 12 hours to obtain a magnesium salt as the Additive PEO-based composite solid electrolyte. It is then punched into a 19mm diameter disc for use.

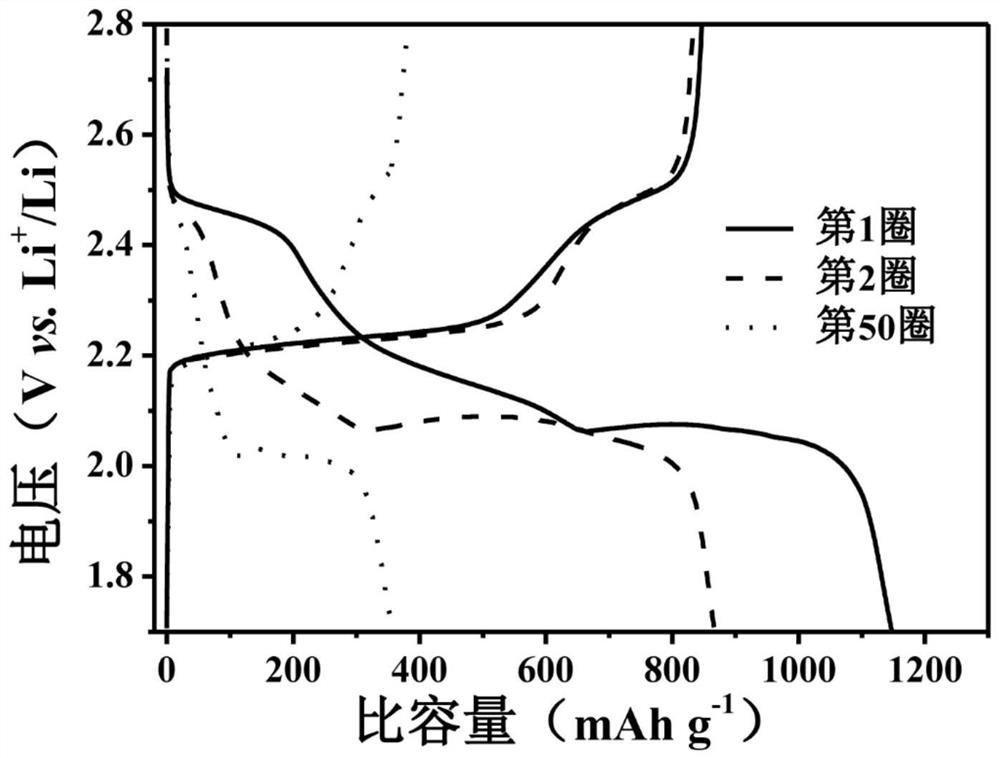

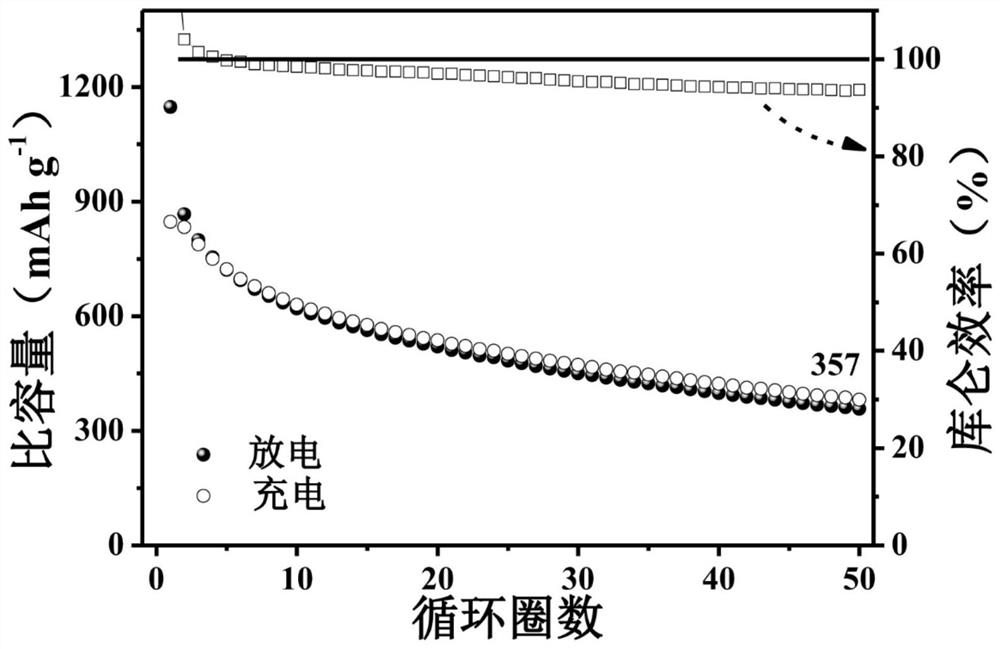

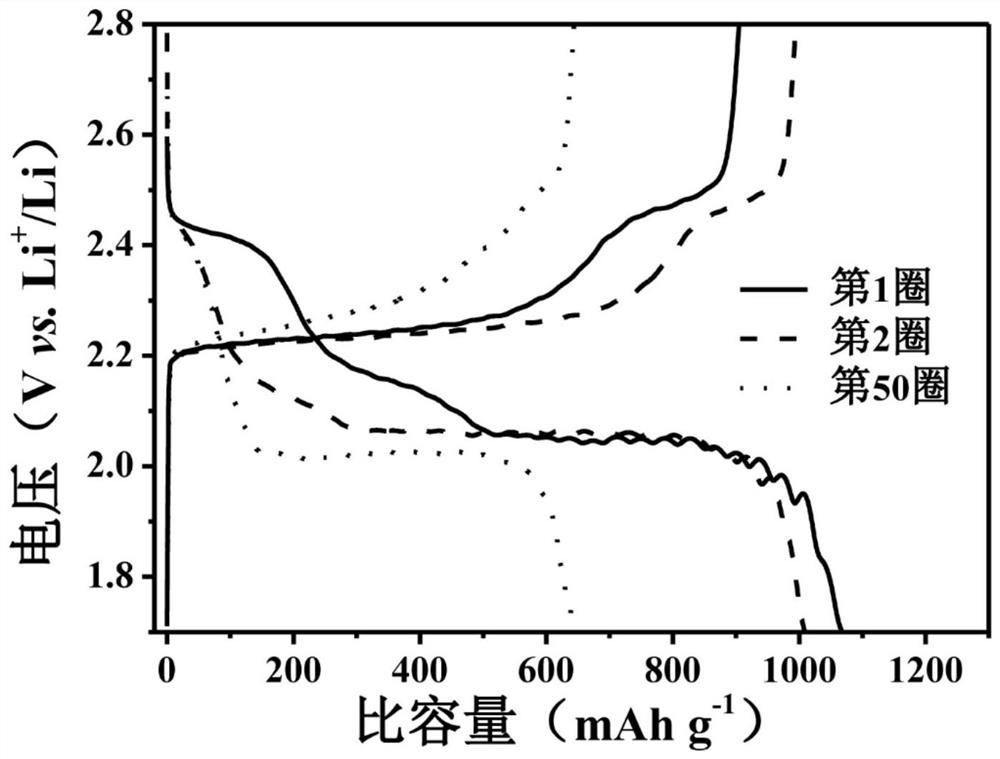

[0037](2) Assemble the sulfur / carbon positive electrode, the PEO-based composite solid-state electrolyte with magnesium salt as additive prepared in step (1), and the lithium metal foil negative electrode into an all-solid-state lithium-sulfur battery and conduct elec...

Embodiment 2

[0039] (1) Weigh 0.4344g lithium bistrifluoromethanesulfonimide (LiTFSI), 0.0200g Mg(TFSI) 2 and 0.1500g β-cyclodextrin were placed in a 100mL flat-bottomed flask, then 12.5000g of acetonitrile solvent (AN) was added, ultrasonicated for 10min at 25°C, stirred for 10min, and after a uniform suspension was formed, 1.0000g of polyethylene oxide ( PEO), stirred at room temperature for 12 hours to obtain a slurry; poured the obtained slurry into a mold, stood for 8 hours until the solvent was completely volatilized, and then transferred to a vacuum drying oven at 60 °C for 12 hours to obtain a magnesium salt as the Additive PEO-based composite solid electrolyte. It is then punched into a 19mm diameter disc for use.

[0040] (2) Assemble the sulfur / carbon positive electrode, the PEO-based composite solid-state electrolyte with magnesium salt as additive prepared in step (1), and the lithium metal foil negative electrode into an all-solid-state lithium-sulfur battery and conduct ele...

Embodiment 3

[0042] (1) Weigh 0.4344g lithium bistrifluoromethanesulfonimide (LiTFSI), 0.0300g Mg(TFSI) 2 and 0.1500g β-cyclodextrin were placed in a 100mL flat-bottomed flask, then 12.5000g of acetonitrile solvent (AN) was added, ultrasonicated for 10min at 25°C, stirred for 10min, and after a uniform suspension was formed, 1.0000g of polyethylene oxide ( PEO), stirred at room temperature for 12 hours to obtain a slurry; poured the obtained slurry into a mold, stood for 8 hours until the solvent was completely volatilized, and then transferred to a vacuum drying oven at 60 °C for 12 hours to obtain a magnesium salt as the Additive PEO-based composite solid electrolyte. It is then punched into a 19mm diameter disc for use.

[0043] (2) Assemble the sulfur / carbon positive electrode, the PEO-based composite solid-state electrolyte with magnesium salt as additive prepared in step (1), and the lithium metal foil negative electrode into an all-solid-state lithium-sulfur battery and conduct ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com