Preparation method of semiconductor substrate layer and preparation method of solar cell

A semiconductor and substrate layer technology, applied in the field of solar cells, can solve the problem of high reflectivity of silicon substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

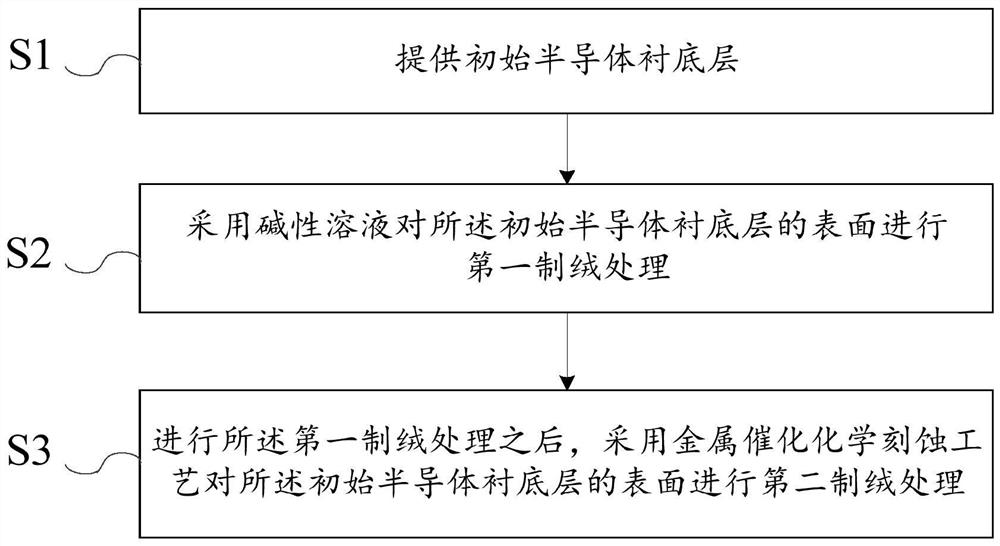

[0038] This embodiment provides a method for preparing a semiconductor substrate layer, such as figure 1 shown, including the following steps:

[0039] Step S1: providing an initial semiconductor substrate layer;

[0040] Step S2: using an alkaline solution to perform a first texturing treatment on the surface of the initial semiconductor substrate layer;

[0041] Step S3: After the first texturing treatment is performed, a second texturing treatment is performed on the surface of the initial semiconductor substrate layer by using a metal-catalyzed chemical etching process.

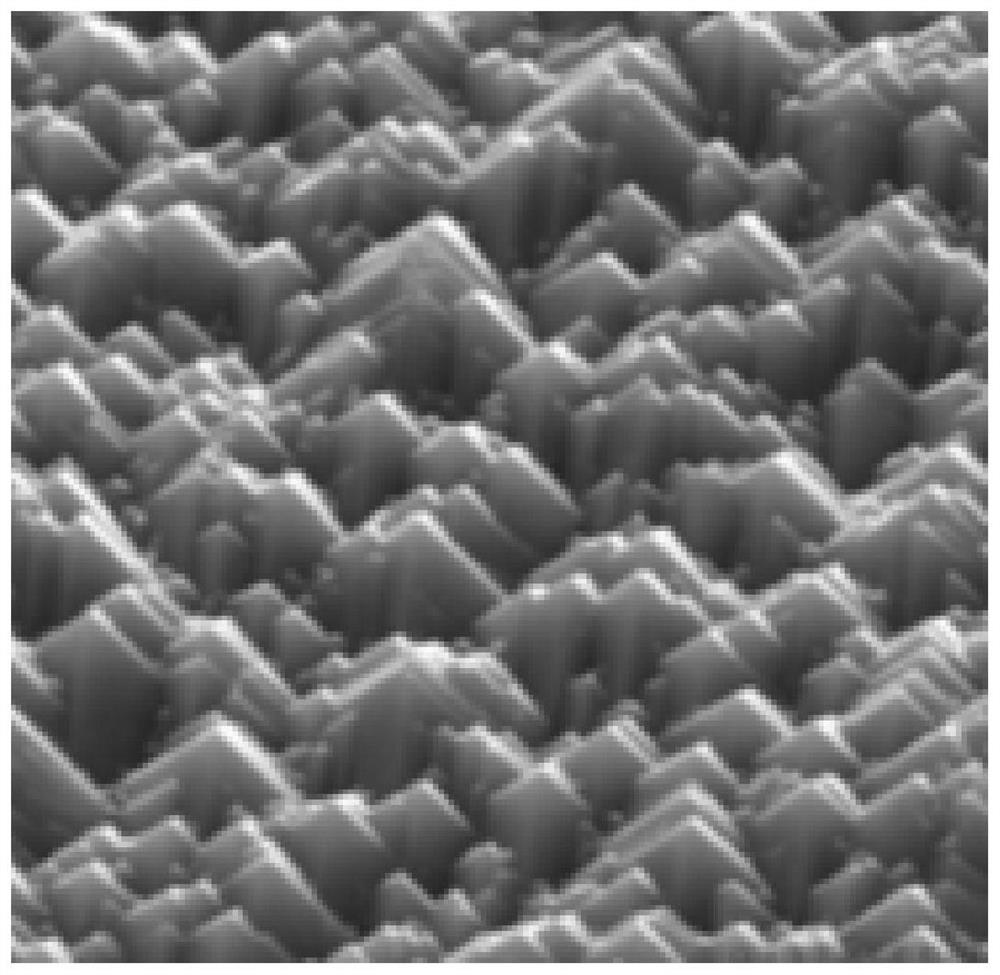

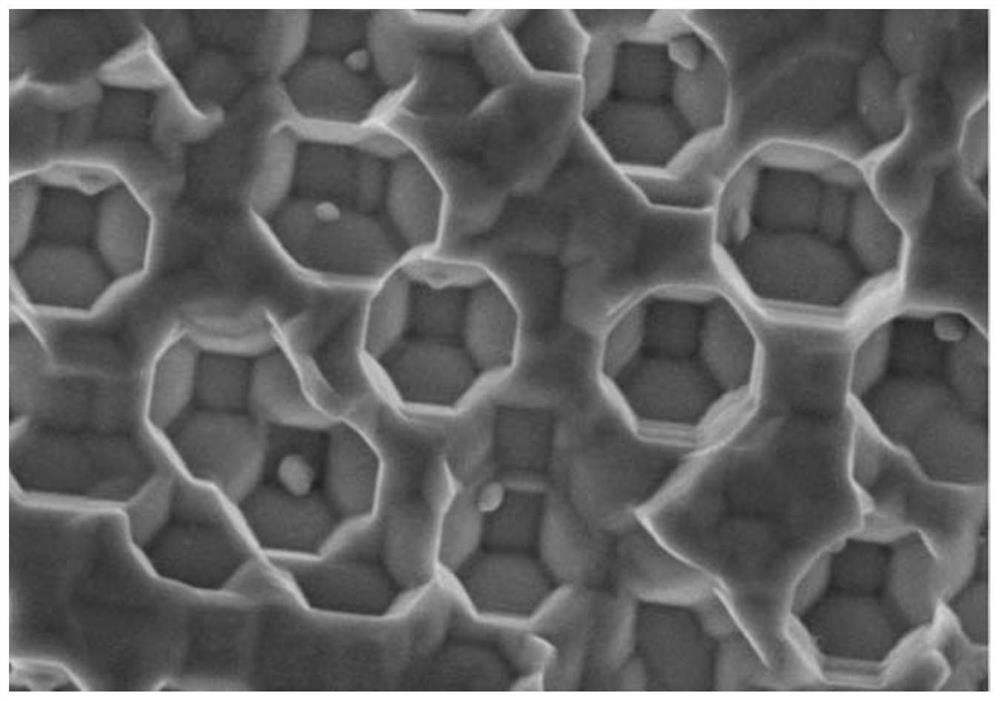

[0042]If a conventional method is used to form a textured surface directly on the semiconductor substrate layer by a metal-catalyzed chemical etching process, the reflectivity of the textured surface will be relatively high, which is not conducive to the entry of light into the solar cell, resulting in a decrease in the current density of the solar cell. In the present invention, the surface of the init...

Embodiment 2

[0056] This embodiment provides a method for fabricating a solar cell, including: forming a semiconductor substrate layer, where the semiconductor substrate layer is formed by using the method for fabricating a semiconductor substrate layer. A textured structure is formed on the surface of the semiconductor substrate layer, and the textured structure is in the micrometer scale and is only a very thin part of the layered structure of the solar cell. Generally, the thickness dimension of the solar cell is 10,000 times to 100,000 times the thickness dimension of the textured structure.

[0057] Optionally, it further includes: forming a first intrinsic passivation layer on one side surface of the semiconductor substrate layer; forming a second intrinsic passivation layer on the other side surface of the semiconductor substrate layer; A first doped semiconductor layer is formed on a surface of an intrinsic passivation layer away from the semiconductor substrate layer; a second dop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com