Air purification adsorption material as well as preparation method and application thereof

An air purification and adsorption material technology, applied in chemical instruments and methods, separation methods, adsorbed water/sewage treatment, etc., can solve the problems of increasing adsorbent treatment costs, excessive adsorption, low adsorption efficiency, etc., to avoid uneven load. , to avoid clogging pores, high adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the air purification adsorption material provided in the embodiment of the present application includes:

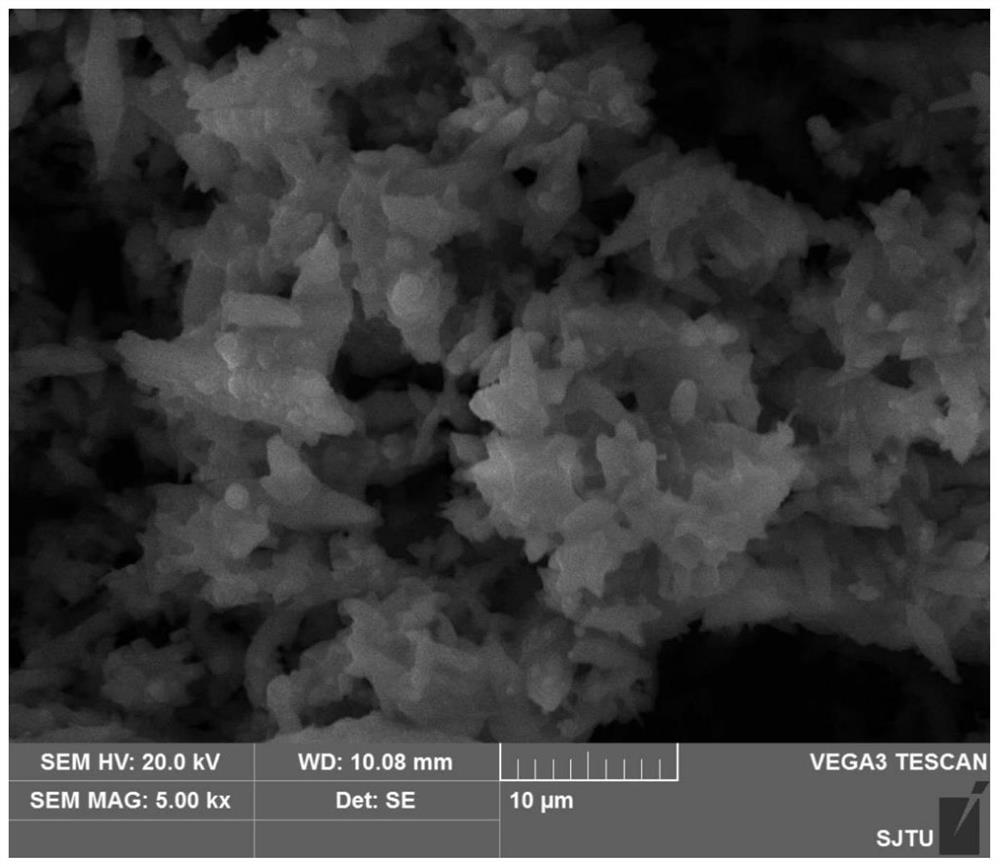

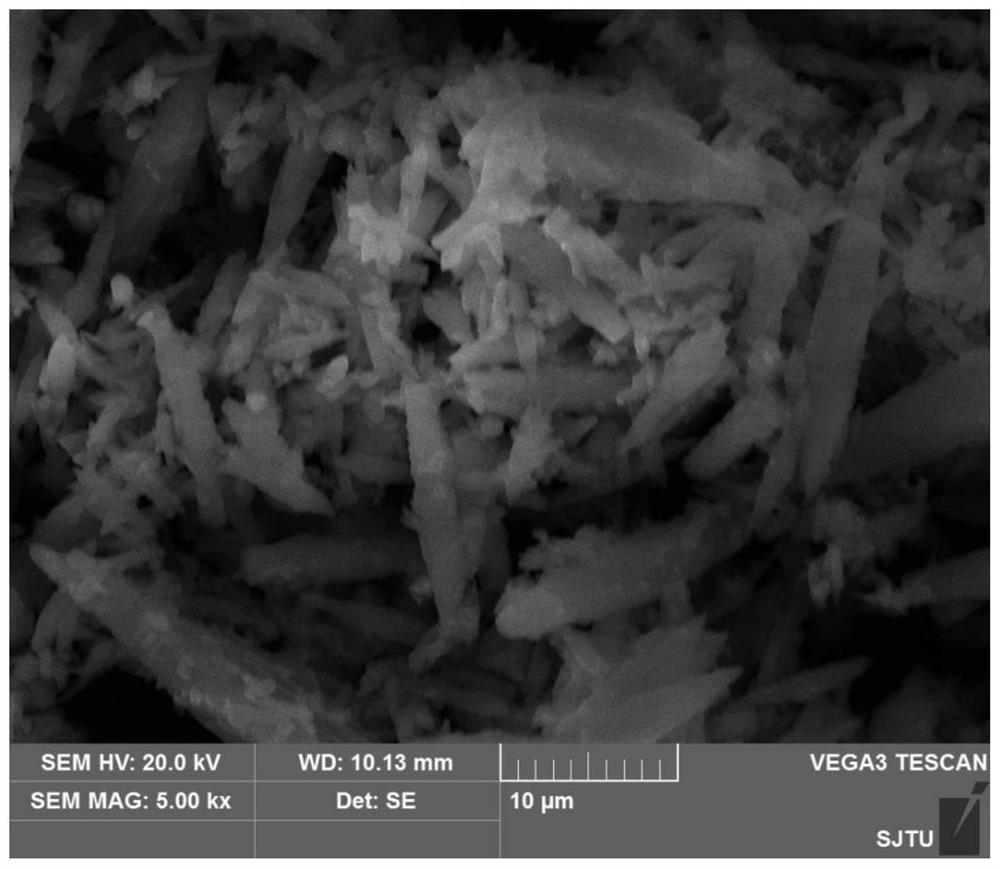

[0033] The raw materials of the following components are mixed and granulated by mass percentage: 20-40% activated alumina powder, 20-40% activated carbon powder, 25-35% magnesium oxide powder, 2.2-7% binder and 8-12.8% water, and granulation to obtain the first primary adsorption material;

[0034] Immerse the first primary adsorbent material in the active component solution, so that the active component is loaded on the first primary adsorbent material to obtain the second primary adsorbent material, and the active component solution contains thiosulfate with a concentration of 50-500g / L and the concentration is 50-500g / L potassium carbonate, and the thiosulfate includes at least one of sodium thiosulfate, potassium thiosulfate and magnesium thiosulfate.

[0035] The preparation method provided in this application,

[0036] First, the ...

Embodiment 1

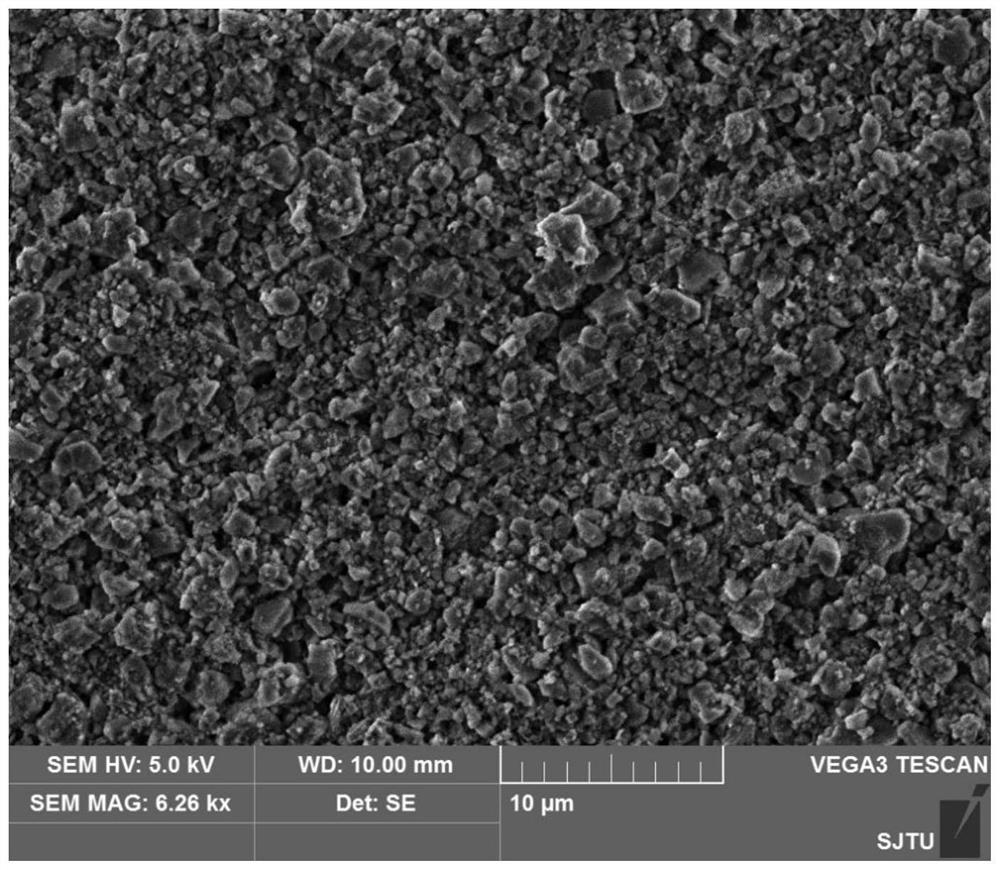

[0056] According to mass percentage, the following raw materials will be prepared: 25% activated alumina powder, 35% activated carbon powder, 25% magnesium oxide powder, 5% binder and 10% water. The specific surface area of activated carbon is about 1000-1200m 2 / g, the specific surface area of activated alumina powder is about 1000 ~ 1200m 2 / g.

[0057] Prepare a sufficient amount of active ingredient solution containing 250 / L thiosulfate and 250 g / L potassium carbonate.

[0058] The activated alumina powder, activated carbon powder, magnesium oxide powder, binder and water were placed in a mixer for mechanical stirring. The stirring speed was 500r / min and the stirring time was 5h. In order to ensure that the components could be mixed and dispersed more uniformly, During the stirring process, ultrasonic dispersion was performed, and the ultrasonic power was 1000W.

[0059] The mixed material obtained after mixing uniformly was placed in a disc granulator for granulati...

Embodiment 2-12

[0063] Examples 2-12 are basically the same as Example 1, except that the proportions and some operating parameters are different, and the specific settings are shown in Table 1.

[0064] Table 1 Specific Settings of Embodiments 2-12

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com